Piping Vibration Analysis - Case Studies

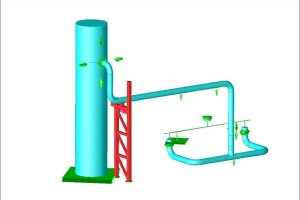

A 16” Line On A Chemical Plant

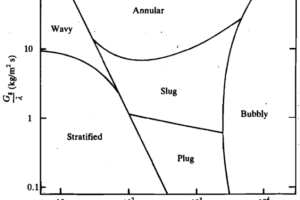

In this case study, we addressed a notable vibration issue observed in the main 16” line at a chemical plant, which was suspected to stem from slug flow. Specifically, the concern centered around the 16” pipe connection linking a low-temperature separator and a heat exchanger.

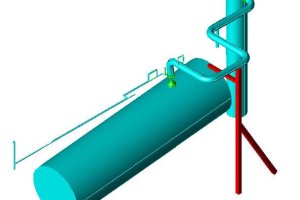

Vibration Reduction In A Process Piping Project

In this case study, the focal point was addressing the high vibration levels observed in the process piping extending from a heat exchanger to a separator.

Given space limitations, modifying the pipe support system or the separator vessel nozzle was deemed undesirable. Thus, the client sought solutions to mitigate the vibration levels without resorting to extensive modifications.

Vibration Enhancement In An Oil Wash Line

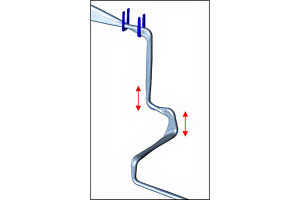

In this case study, we encountered undesirable vibrations in the downstream line of an angle control valve within a wash oil line.

Given these observations, DRG was engaged to investigate and mitigate the vibrations within the system.

Dynamic Stress And Vibration Analysis For A Gasoil Hydrofiner

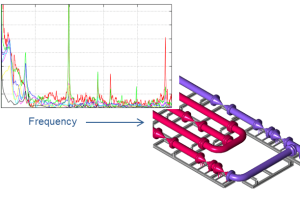

During the start-up and normal operation phases of a Gasoil Hydrofiner system, significant vibrations were observed in its piping. These vibrations, described as “large amplitude,” were particularly concerning. The unit’s piping was divided across four separate pipelines.

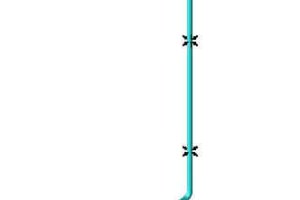

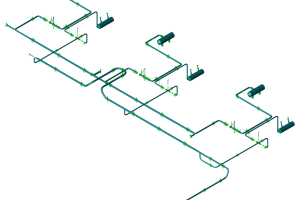

Vibration Analysis For Piping Connected To Hydrogen Compressors

In the past, visible vibrations were observed in the piping connected to hydrogen compressors. These vibrations were particularly noticeable in the small-bore pipes branching off from the main pipes. Over time, these small-bore pipes frequently developed cracks, likely due to fatigue.

Pulsation and Vibration Analysis of a Gas Compression Station

In this case study, we explored the pulsation and vibration phenomena at a gas compression station equipped with four centrifugal compressors. These compressors generate flow pulsations due to the action of the impellors, which can excite the system’s acoustic and mechanical natural frequencies.

Two-Phase Flow Analysis of Fuel Jetty Terminal

A fuel jetty terminal operator expressed concerns about potential two-phase flow issues during off-loading operations. The client indicated that trapped nitrogen used for purging lines could mix with the liquid being off-loaded when empty ship tanks were flushed with inert nitrogen.

Assessment of Vibrating Process Line

Large amplitude vibrations in a process line have resulted in damage to several pipe supports. DRG was engaged to identify the root cause of these vibrations, assess potential fatigue issues, and recommend remedial actions for the client.

Noise and Vibration Analysis of a Metering Skid

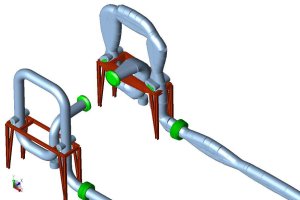

A gas metering skid is being designed for use in a flow station. DRG was commissioned by a client to conduct a comprehensive noise and vibration study of the metering skid to assess its vulnerability to fatigue failure.

Vibration Level Assessment: Resonance Models and Fatigue Check

This case study focuses on the vibration assessment of a pentane line, specifically evaluating vibration stresses and the risk of fatigue issues at the nozzle/shell interfaces.

Vibration Analysis of Hydrogen Cyanide (HCN) Line in Slug Flow Regime

A comprehensive vibration analysis was conducted on a water feed line operating in a slug flow regime. Slug flow, characterized by large intermittent fluid slugs within the pipeline, can exert significant dynamic forces on piping systems, potentially leading to structural failures.