Introduction

In this case study, we addressed a notable vibration issue observed in the main 16” line at a chemical plant, which was suspected to stem from slug flow. Specifically, the concern centered around the 16” pipe connection linking a low-temperature separator and a heat exchanger. Dynaflow Research Group was tasked with investigating this vibration phenomenon.

Analysis

Our analysis began with an examination of two-phase flow data, revealing indications of slug flow within the horizontal pipes of the system. We employed two distinct profiles for analysis: one with a 1-second interval between smaller slugs and another with a 10-second interval between somewhat larger slugs. These slug profiles served as the basis for evaluating the existing system’s performance under its current support configuration.

Upon conducting the analysis using the CAESAR II software package, it became evident that the original system’s nozzle 3 of the separator experienced excessive loads and moments due to the presence of slug flow. Particularly with the 10-second slug profile, stresses exceeded allowable limits at several points.

Results

To address these findings, we implemented several modifications to enhance the system’s support arrangement:

- Introduction of an axial stop, in addition to the existing guide and +Y- support, with a potential 20 mm gap.

- Addition of an extra vertical support on the header.

- Incorporation of a guide with a 1 mm gap and inclusion of a vertical hanger to alleviate static load on nozzle 3.

- Installation of a steel structure with side bracing, along with a snubber between the steel structure and the piping, to mitigate rapid dynamic movement.

Following the implementation of these modifications, all stresses within the system remained within acceptable limits, effectively addressing the vibration issue.

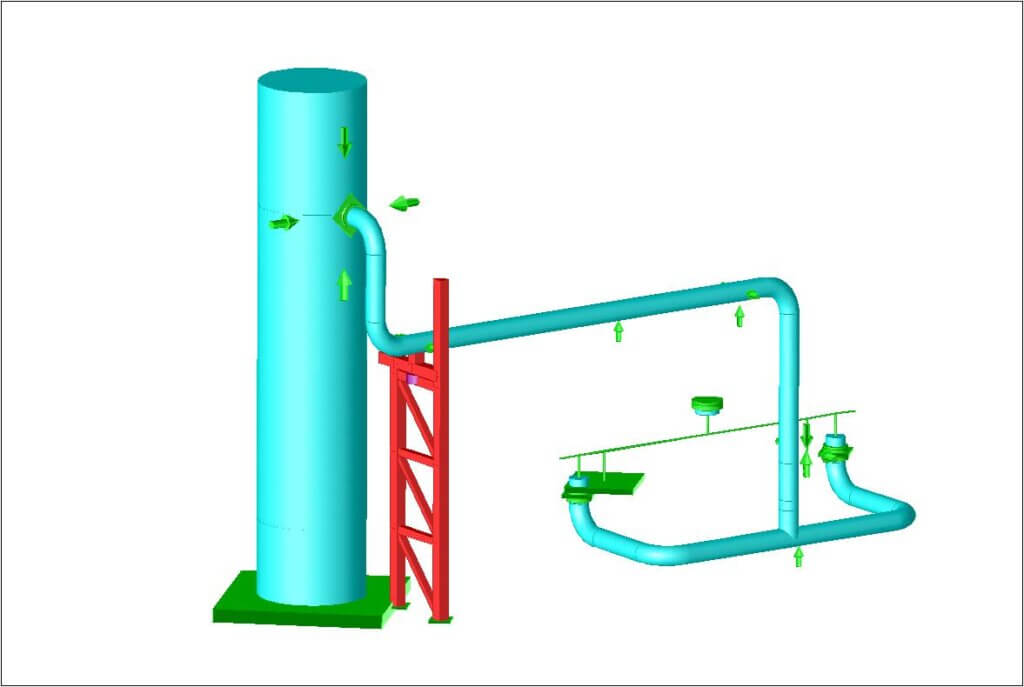

“A steel structure with side bracing was introduced.”

With these modifications applied to the system, all stresses remained within the allowable margins.