Surge Analysis Simplified

The most intuitive and efficient tool for the analysis of surge, water hammer, and general flow conditions within piping systems.

BOSfluids enables you to perform surge analyses in an interactive and visual way, giving you lots of opportunities for exploring your problem space quickly and efficiently.

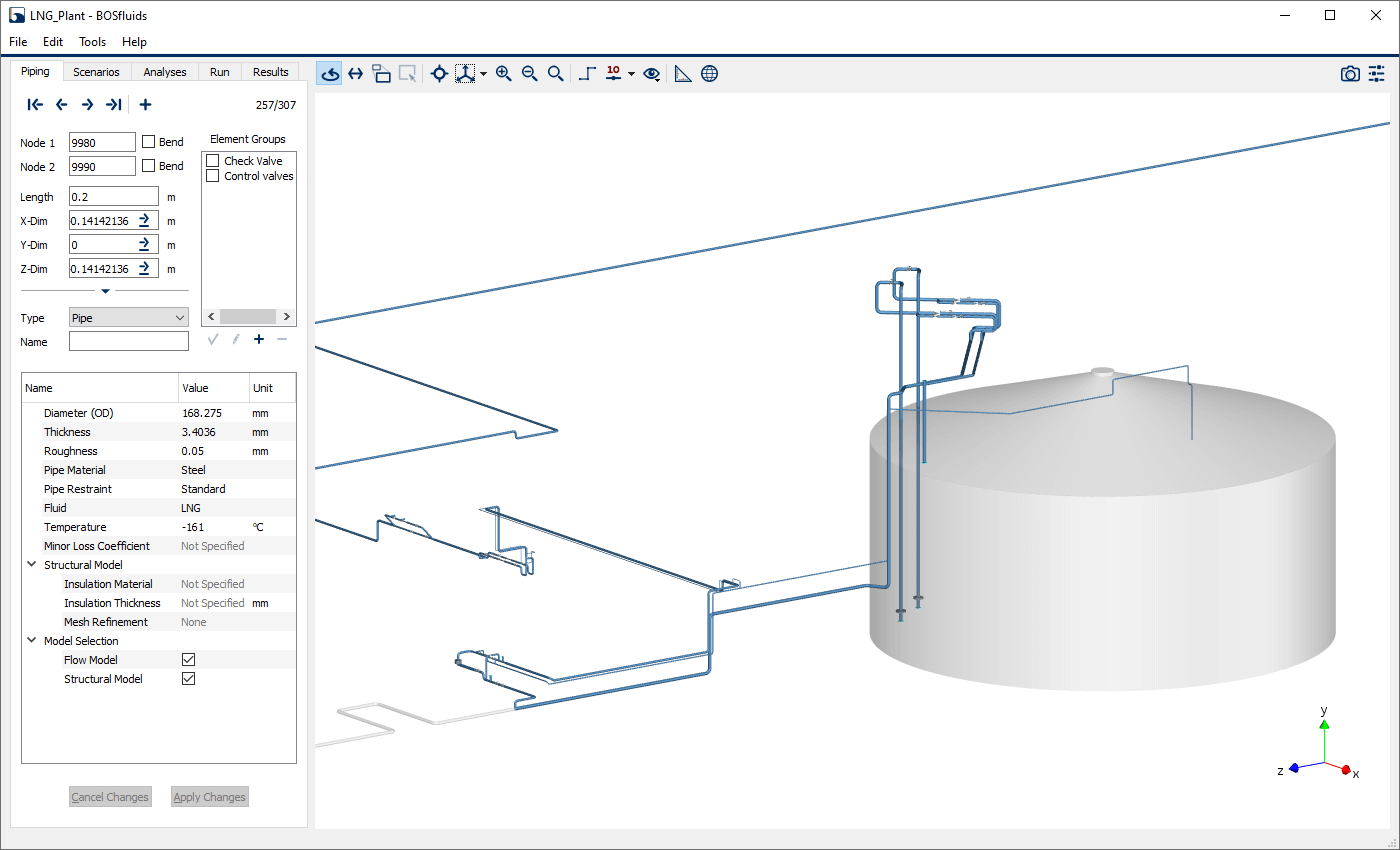

BOSfluids is more than a surge analysis tool as it can simulate general steady-state and transient flow conditions in piping systems, and help you perform coupled fluid-structure analyses.

Developed by engineers, for engineers

What You Can Do With BOSfluids

Define any model parameter as a symbolic parameter and observe how the variation of those symbolic parameters affects the steady-state process conditions. Combine this with the possibility to define custom data sets and find the optimum conditions according to the relevant criteria.

By using variation plots you can graphically correlate orifice dimensions with the flow conditions at any point in a piping system. This not only enables you to select the optimal orifice dimensions but also enables you to understand the effect of an orifice plate on the flow conditions.

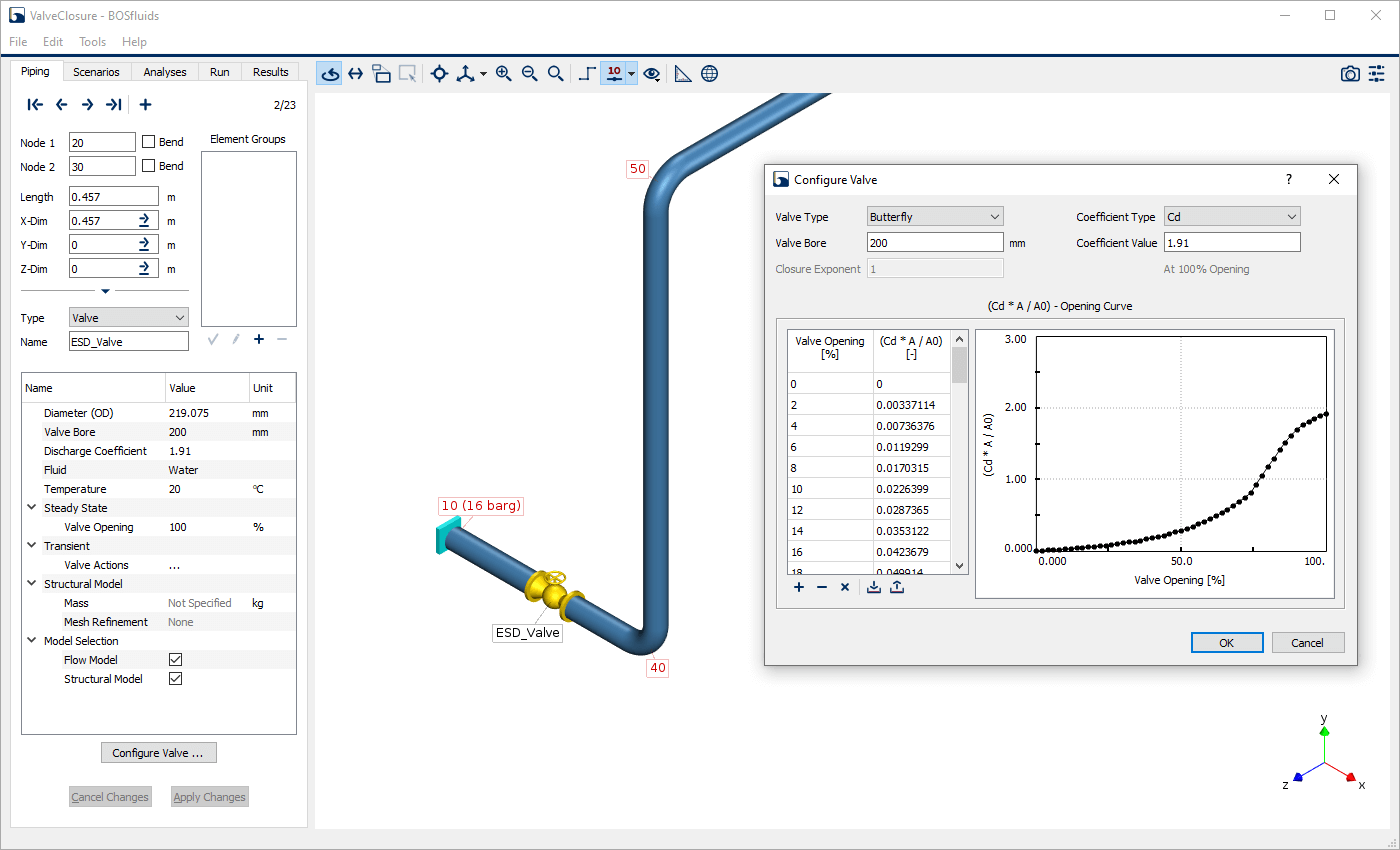

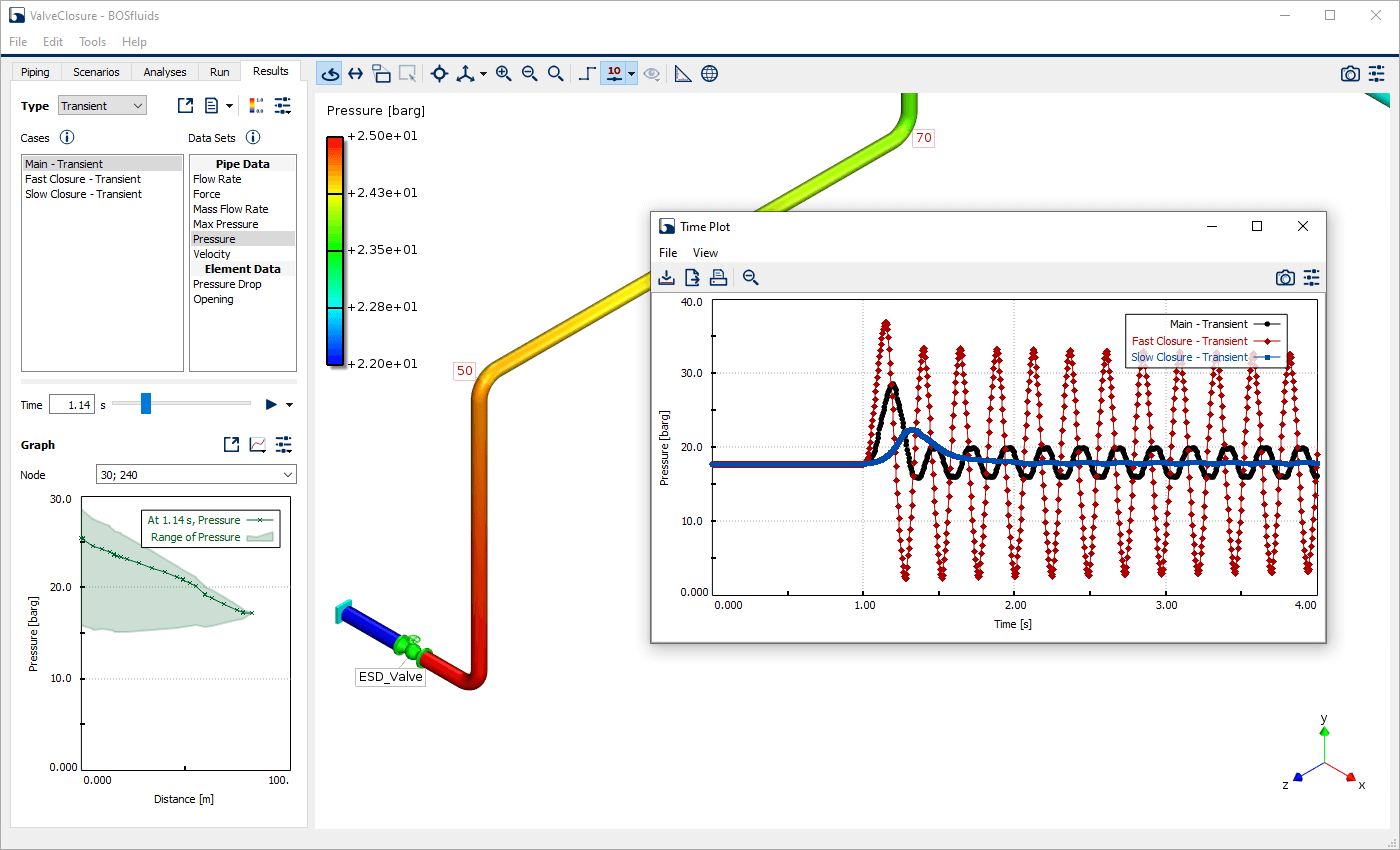

Emergency shutdown procedures, and any situations involving rapid valve closures, can lead to high pressures and loads on a piping system. With BOSfluids you can efficiently assess the impact of valve closure times and determine how a piping system can be protected from unsafe situations.

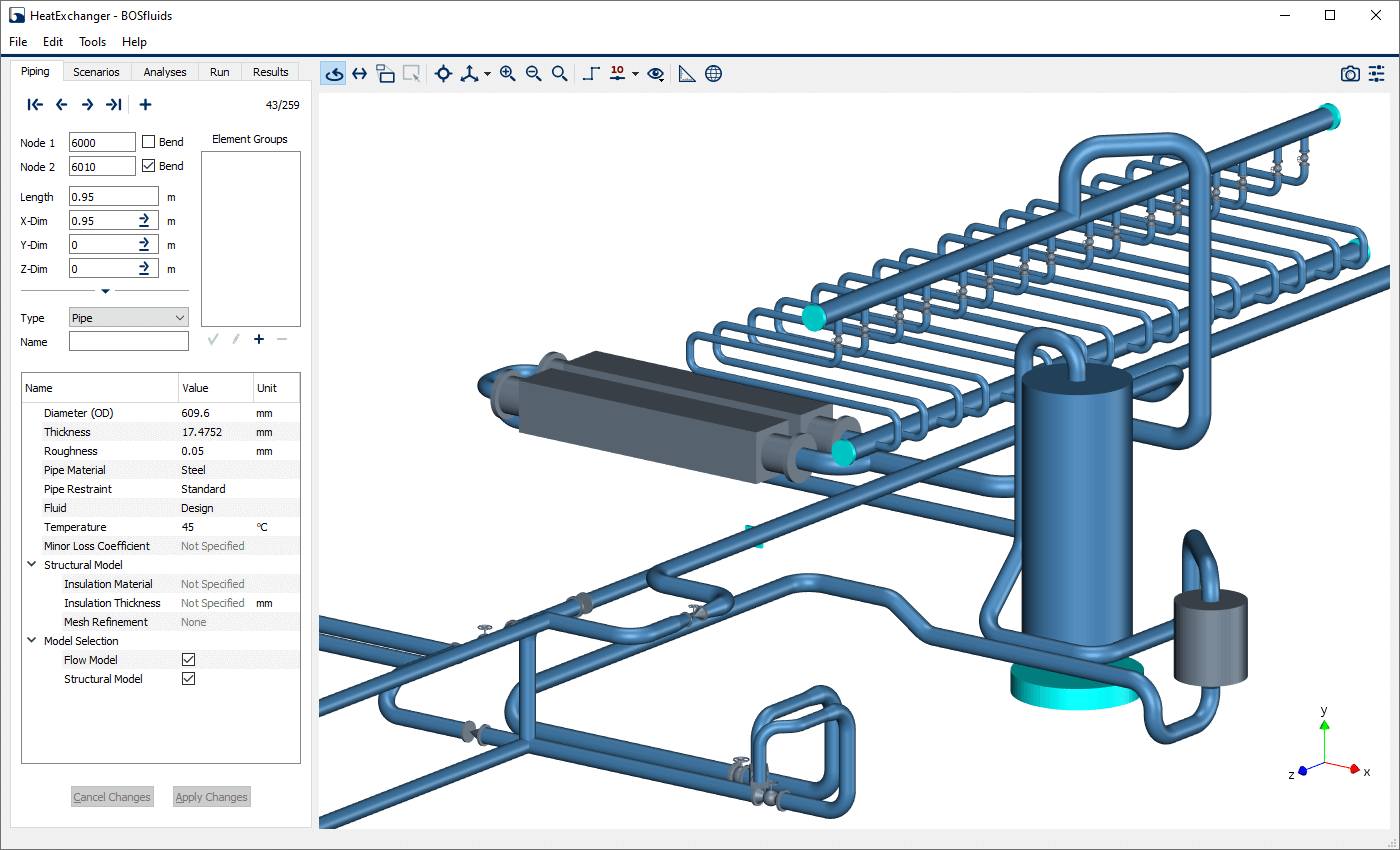

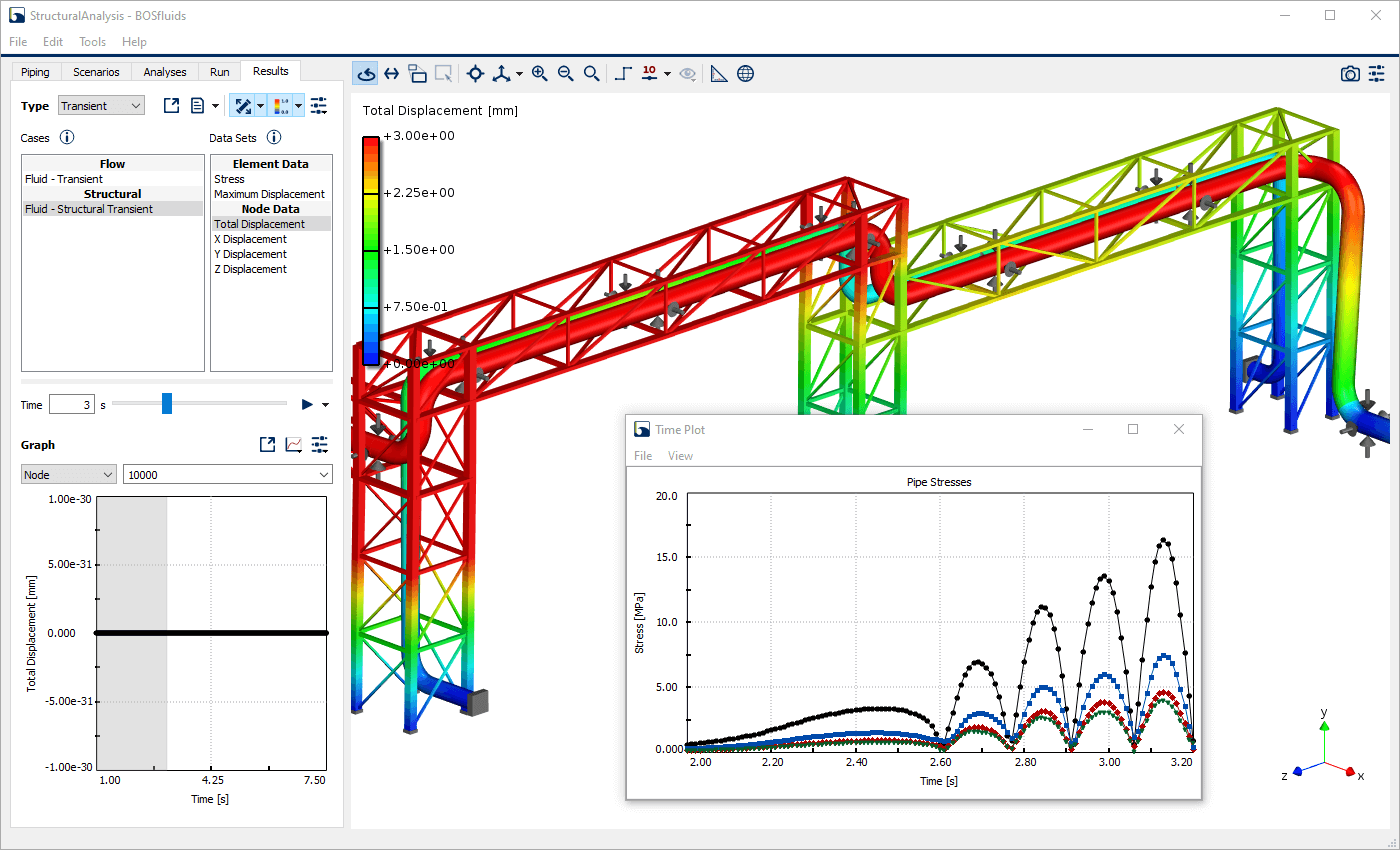

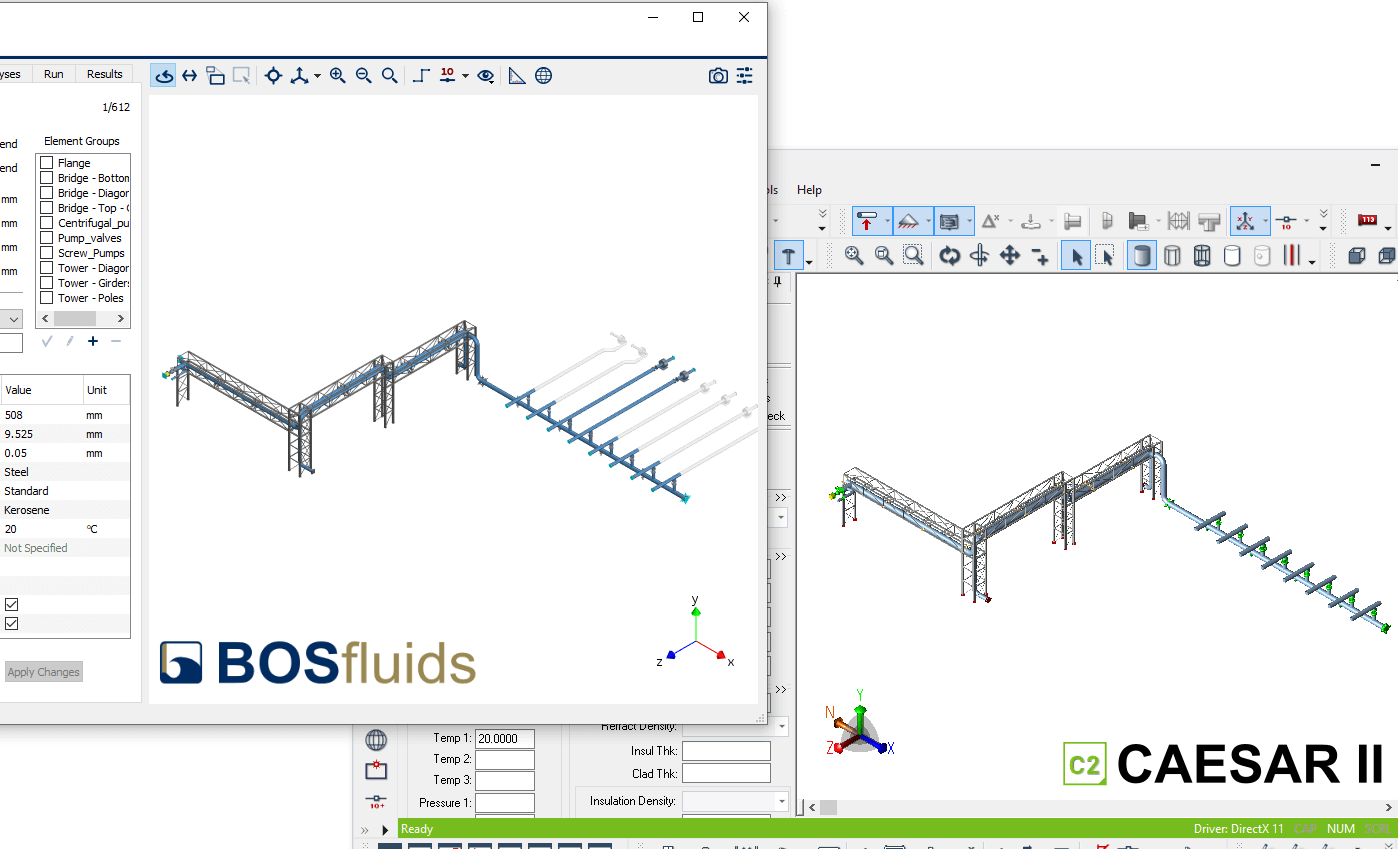

Transient pressure waves can lead to significant fluid-induced forces acting on a piping system. Because of the unique support for working with 3-D piping models, BOSfluids integrates very well with various pipe stress solvers. This enables you to accurately predict the structural response of a piping system due to the fluid-induced forces.

By using the excellent Piping Component File interface in BOSfluids you can reduce the scope for modeling errors and save a large amount of time when setting up a piping model. With BOSfluids you can import large collections of Piping Component Files that are automatically assembled into a coherent piping model.

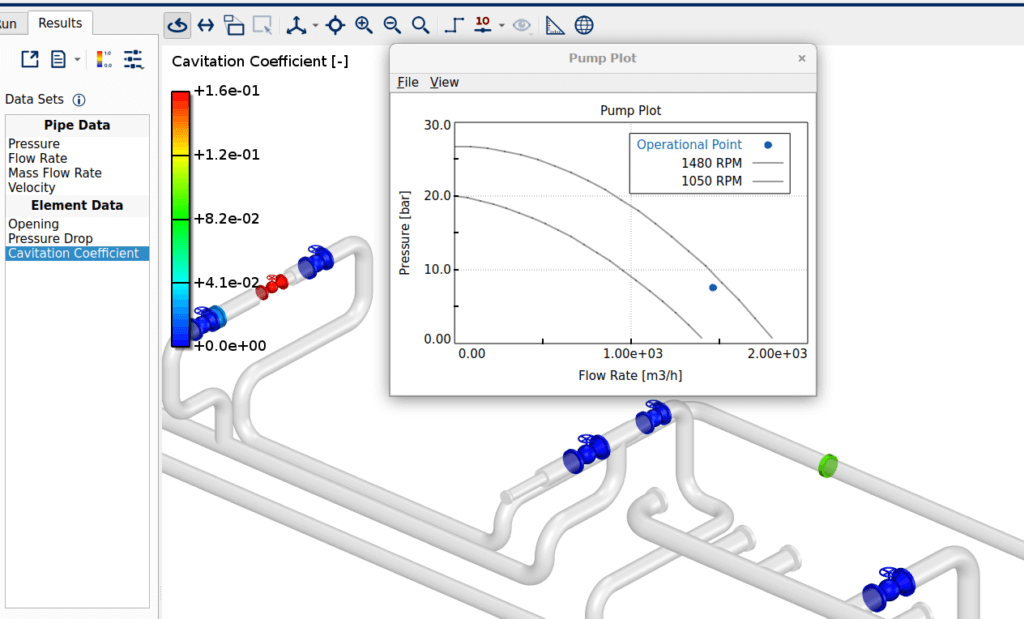

Pump startup and pump failure situations can lead to severe transient flow conditions in piping systems. With a robust and versatile pump model, BOSfluids enables you to simulate and assess these situations efficiently, even when little data on a pump is available.

BOSfluids provides extensive support for implementing and simulating control systems, ranging from simple switches to full PID control systems. A programmable interface allows you to integrate the output from multiple sensors to determine the speed of a pump or the opening of a control valve.

BOSfluids implements a robust, fast, and accurate two-phase flow model with which you can simulate the rapid filling of fire water systems. This model also enables you to perform vessel blow-down simulations and to simulate the draining of fuel systems.

Using the tube rupture model provided by BOSfluids, you can accurately simulate a wide range of scenarios involving the rupture of one or more tubes in a heat exchanger. The tube rupture model provides support for tubes filled with a gas or a liquid. It also supports the flashing of a liquid, both within a tube and at the rupture.

See BOSfluids In Action

BOSfluids Capabilities

Single-phase flow

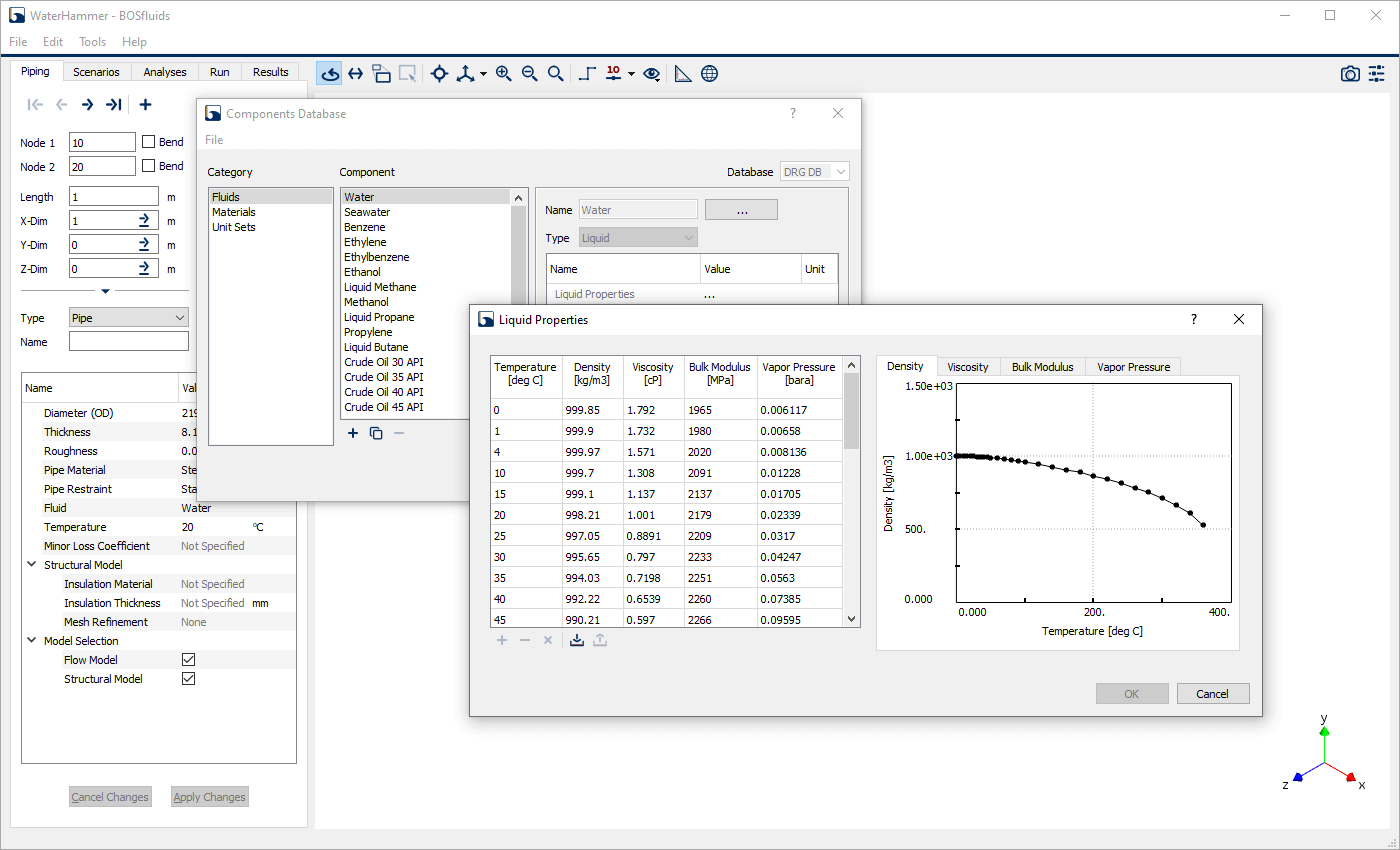

BOSfluids simulates single-phase fluid flow through piping systems, assuming the fluid properties are homogeneous and that the flow conditions are uniform over any cross-section of the This produces accurate results over a wide range of piping and fluid flow applications.

Two-phase liquid/gas flow

BOSfluids also simulates two-phase liquid-gas flow conditions where it is reasonable to assume a clearly defined liquid-gas interface perpendicular to the axis of the pipe. This supports simulation of rapid filling of an empty firewater system or the draining of a fuel system.

Cavitation formation and collapse

Both the single-phase and two-phase flow models can be combined with a cavitation model to simulate the pressure waves resulting from the collapse of vapor and gaseous cavities. All cavitation models in BOSpulse have been extended so that they can handle cavities larger than the calculation cell size.

Modeling elements

BOSfluids supports the modeling of most real-world piping systems through a collection of special flow elements, including: reducers, orifices, valves, check valves, air valves (vacuum breakers), safety relief valves, regulator valves, pumps, surge vessels, storage tanks.

BOSfluids also offers a special flow element for simulating tube rupture in heat exchangers.

BOSfluids includes a flexible framework for implementing control systems. Through the user-defined coupling of sensors, transfer functions, and controllers, BOSfluids can simulate control systems from simple switches to sophisticated PID controllers.

Solvers

The BOSfluids steady state solver is based on a non-linear, implicit solution method that takes the compressibility of gases into account.

The BOSfluids quasi-steady state solver essentially calculates a series of steady-state solutions to analyze slowly–evolving flow conditions over long periods of time.

The BOSfluids transient solver accurately analyzes fast-changing transient flow conditions involving the propagation of pressure waves. This solver uses the method of characteristics and a novel grid coarsening method to solve the time-dependent and non-linear flow equations in a robust and very efficient way.

Both the steady state and the transient solver can handle piping systems involving fluid properties that vary in space.

Key Features Of BOSfluids

BOSfluids provides a robust platform for analyzing various flow conditions in piping systems, accommodating both steady state and transient scenarios for gases or liquids in systems of any size.

Its steady-state capabilities accurately model pressure losses and flow rates in complex piping systems, automatically refining models for precise results. The transient solver quickly evaluates time-dependent conditions like startups, emergencies, and operational changes, employing advanced techniques for accuracy without demanding expertise.

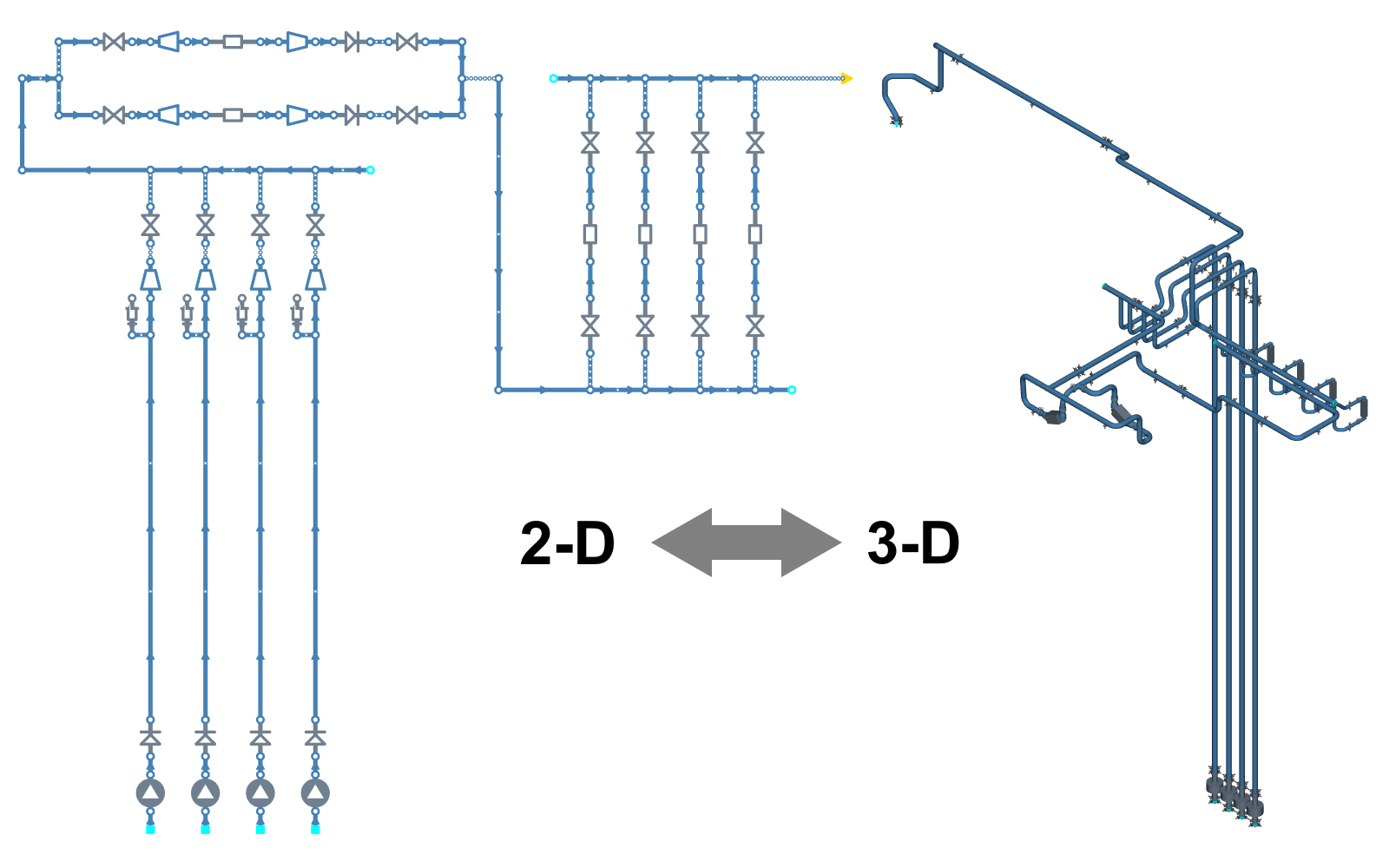

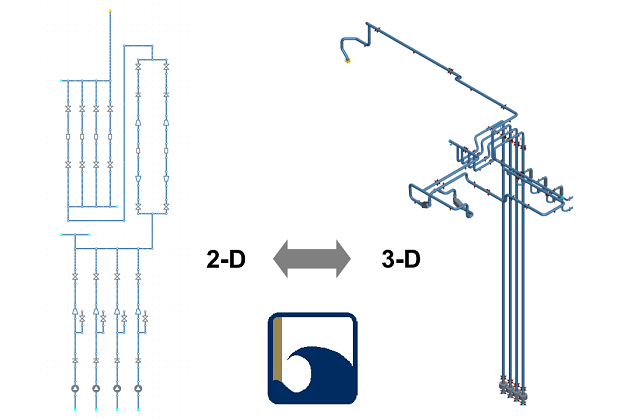

Notably, it supports both 2-D network and 3-D piping models, integrating well with CAD systems. Additionally, it allows symbolic parameter specification, facilitating parameter studies for understanding flow condition dependencies and template creation with adjustable parameters.

BOSfluids introduces a two-phase flood and drain model, vital for predicting liquid forces in piping systems. It can simulate the rapid filling of empty or gas-filled pipes, crucial for firewater systems.

The flood and drain model can be used, among others, to simulate the flooding of dry firewater systems and the draining of fuel systems by flushing them with gas.

The flood and drain model handles complex pipe layouts efficiently, considering interactions with deluge nozzles and air valves. It extends BOSfluids’ capabilities from single-phase to two-phase flow scenarios like slug loads and vessel blow-downs.

This model ensures computational efficiency, enabling analyses of large systems in a timeframe similar to single-phase simulations.

BOSfluids is a comprehensive tool for simulating flow conditions in piping systems, accounting for various elements like fittings, valves, equipment, vessels, and control systems. It offers an extensive collection of flow element types to predict pressure losses and dynamic behaviors accurately

- Fittings such as elbows and reducers are accounted for with automatic minor loss coefficients.

- Valves, including check valves and relief valves, are modeled with options for pressure loss curves and dynamic behaviors.

- Equipment like pumps and compressors can be specified with detailed curves or generated automatically.

- Control systems can be used to adjust flow elements in response to changes in the flow conditions or to external events.

In a tube-and-shell heat exchanger, the rupture of a tube can cause overpressure, particularly if the tube-side fluid is a high-pressure gas or a liquid prone to rapid phase changes.

BOSfluids’ tube rupture model simulates high-pressure fluid discharge from ruptured tubes into a low-pressure shell, handling phase transitions and critical/sub-critical flows. It accommodates ruptures at the tube sheet or along tubes, treating flow as nozzle or open-end pipe, considering wall friction losses.

BOSfluids also provides relief valve and burst disk models that support flashing and critical flow. This makes BOSfluids a versatile tool for analyzing tube rupture scenarios, offering comprehensive solutions for industrial safety assessment.

Vapor cavity dynamics play a crucial role in piping system pressure evolution. BOSfluids offers comprehensive support for cavitation modeling via the Homogeneous Vapor Cavity Model (HVCM), Discrete Vapor Cavity Model (DVCM), and Discrete Gas Cavity Model (DGCM).

HVCM assumes homogeneous dispersion or collection of vapor cavities, while DVCM and DGCM consider cavities at flow grid points. HVCM needs no extra parameters and aligns well with experiments. DGCM suits scenarios in which the effects of entrained gas are significant.

All models accommodate multi-grid cell cavities, enabling precise simulation of large cavity behaviors, especially in vertical piping. They’re also compatible with the Flood & Drain model for enhanced functionality.

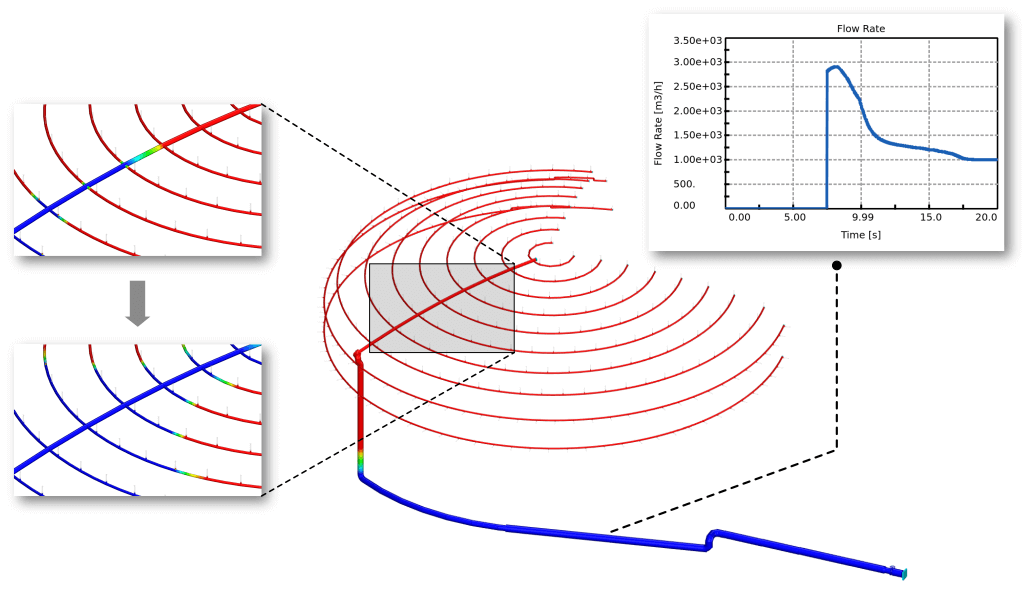

Fast-changing flow conditions can lead to lead to large pressure differences at opposite bends. The resulting loads can seriously affect the integrity of the piping system.

BOSfluids accurately predicts fluid-induced forces on pipes using 3-D models, predicting force magnitude, direction, and timing.

It enables fluid-structure analysis within its interface or via export to compatible tools like CAESAR II and Bentley AutoPIPE. With BOSfluids, a single model covers both flow and structural aspects, including the specification of supports, structural steel elements and stress intensification factors.

This integration streamlines analysis, eliminating the need for separate models in disparate software. This makes BOSfluids a robust solution for comprehensive, efficient analyses of fluid-structure interactions in piping systems.

BOSfluids offers robust flow solvers for steady state and transient analyses, handling complex piping models efficiently.

The steady-state solver uses nonlinear solution methods, optimized for speed with advanced linear algebra techniques.

The transient solver employs the method of characteristics in combination with a novel grid coarsening method to speed up transient analyses in a remarkable way. It automatically performs a convergence check to verify that the results do not depend significantly on the resolution of the underlying flow grid.

BOSfluids optimizes processor core usage, running user interface and simulations concurrently for faster results. Overall, it minimizes wait times, allowing you to focus more on problem solving.

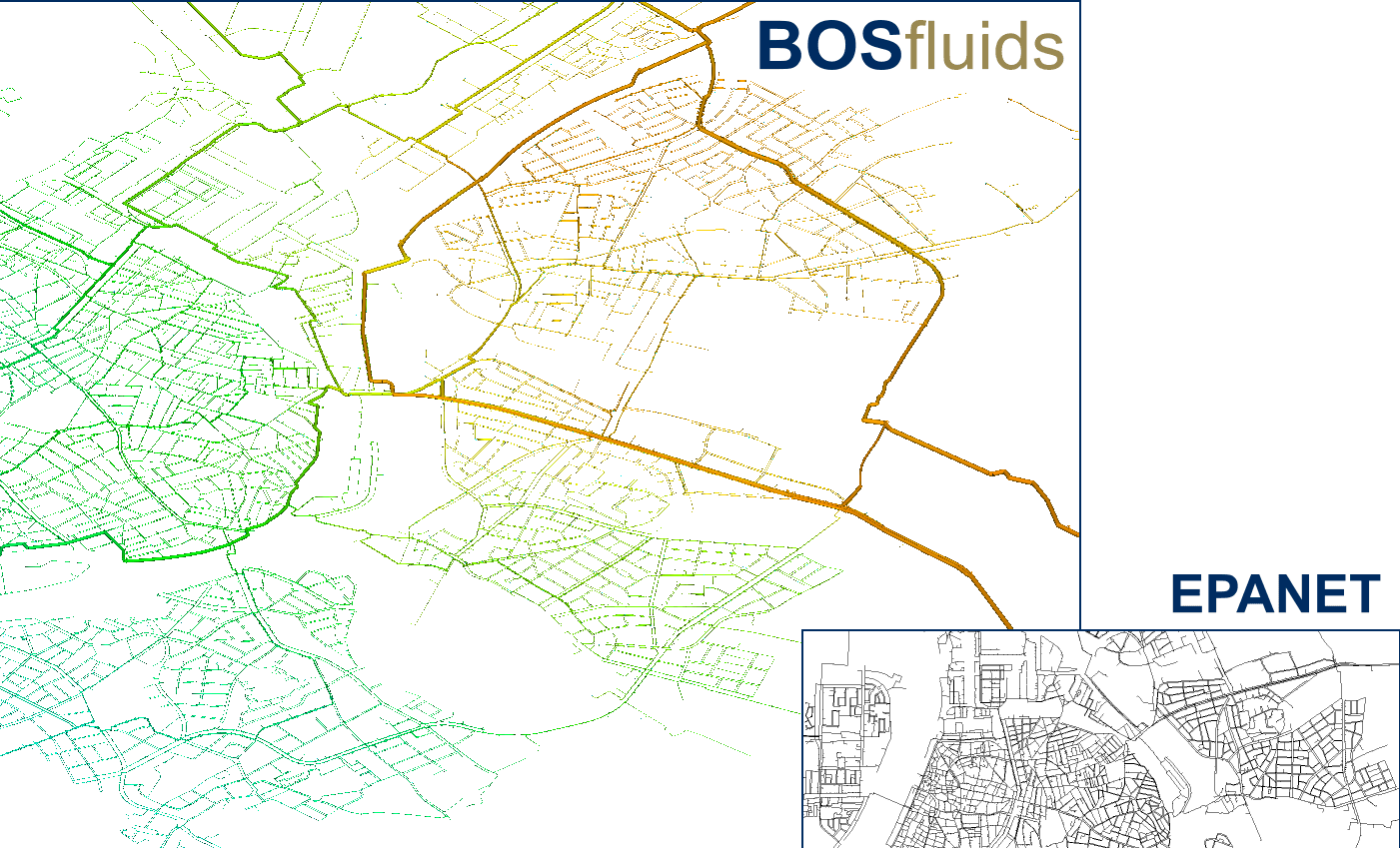

BOSfluids provides you with a wide range of options for building piping models. Not only can you construct intricate models within the software itself, but you can also import models from various file formats like Piping Component Files, CAESAR II neutral files, EPANET model files, and pipe profile spreadsheets.

Upon import, you can choose to replace, extend, or update the current model with the imported geometry, facilitating compatibility with other analysis tools. BOSfluids excels in importing Piping Component Files, where it automatically rectifies common issues like overlapping elements and disjoint piping sections. Because the PCF interface is very efficient it can smoothly process large collections of PCFs without noticeable delays.

BOSfluids allows for the creation of multiple scenarios within a single piping model, each defining specific parameters for analysis. These scenarios enable the examination of various conditions, such as different valve closure profiles, without altering the main model.

Changes made to the main scenario automatically affect all derived scenarios, while alterations to secondary scenarios remain isolated. The software supports an unlimited number of scenarios and efficiently manages differences between them, minimizing storage and processing requirements.

You can perform analyses for multiple scenarios in parallel and compare their results in different ways. This helps you to understand how model parameters affect the flow conditions, facilitating informed decisions for system modifications and design enhancements.

BOSfluids is a comprehensive tool for piping system design and analysis, integrating seamlessly with pipe stress and mechanical software. Its compatibility with 3-D piping models ensures consistency and facilitates data exchange with pipe stress analysis software, minimizing errors.

BOSfluids supports CAESAR II neutral files, enabling seamless import/export of piping components, supports, and structural elements. The “update geometry” function allows for effortless integration of changes made in external software while retaining fluid-related parameters unique to BOSfluids.

This interoperability streamlines workflows and enhances productivity when transitioning between different software tools, making BOSfluids a valuable asset in piping engineering.

BOSfluids offers a versatile user interface for analyzing piping models and presenting results through diverse visualization options like plots and reports. You can review results within the model viewer or via various plots such as min-max, profile, and time history plots.

Additionally, results can be exported to BOSview which can be downloaded and used for free. BOSview is not only capable of displaying BOSfluids models and results but can also display piping models that are stored in different file formats, including Piping Component Files.

Notably, BOSfluids prioritizes open formats for model and results storage, facilitating data access through Python and Matlab scripts. Even after license expiration, you can view, but not save, models or conduct new analyses.

Resources Available

Training Courses

Learn all about the effects of pressure surges on piping systems and how to perform a surge analysis using BOSfluids.

Webinars

See BOSfluids in action in one of our webinars where we explore the latest uses cases and applications.

Knowledge Base

Check out the latest product releases and articles that answer your technical questions.