Vibrations & Dynamics Engineering

Vibrations and dynamic stresses can cause significant damage to your systems, leading to costly downtime, fatigue failure, and operational inefficiencies.

At Dynaflow Research Group, we specialize in identifying, analyzing, and mitigating vibration-related issues to help you maintain the safety, reliability, and performance of your systems. Our comprehensive services cover a range of vibration and fatigue assessments to ensure your system operates smoothly under all conditions.

FLOW DYNAMICS & VIBRATION EXPERTISE

Flow Dynamics and Vibration Solutions for Increased System Reliability

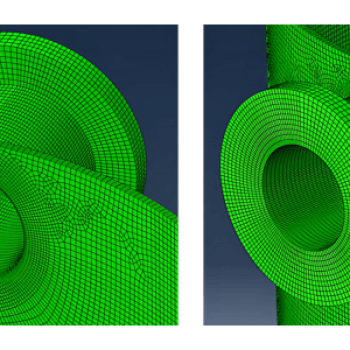

Vibration is a mechanical phenomenon that can result from reciprocating equipment, flow-induced pulsations, or acoustic energy. These oscillations can lead to fatigue failure, operational inefficiency, and even system failure. Our vibration analysis service focuses on identifying the sources of vibration through detailed measurements and simulations.

Benefits

- Early identification of potential vibration risks.

- Prevention of mechanical failure due to fatigue.

- Customized vibration mitigation strategies for design and operational phases.

Fatigue is a critical issue in piping systems subject to cyclic loading and vibrations. Over time, repeated stress can lead to the formation of cracks, compromising the structural integrity of pipelines and equipment. We evaluate the impact of operational loads on the lifespan of your system, ensuring long-term safety and reliability.

Benefits

- Accurate prediction of system lifespan based on operational conditions.

- Prevention of fatigue-induced failures through early detection.

- Optimized maintenance schedules to extend equipment life.

When unexpected failures occur, it is critical to identify the root cause to prevent recurrence. Whether caused by vibrations, fatigue, or other dynamic stresses, our team provides actionable insights to restore safe and efficient operations.

Benefits

- Detailed identification of failure causes, including material or design flaws.

- Implementation of corrective measures to prevent future failures.

- In-depth reporting and recommendations for system improvements.

Applications

Fluid Dynamics & Vibrations Project Examples

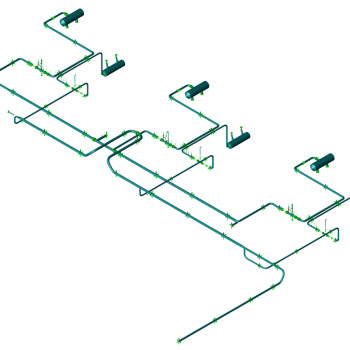

Vibration Anaysis for Piping Connected to Hydrogen Compressors

Vibration Level Assessment: Resonance Models and Fatigue Check

A vibration assessment of a pentane line identified mechanical resonance as the cause of fatigue risks at nozzle/shell interfaces. Modeling confirmed stress levels were within allowable limits, requiring no modifications.

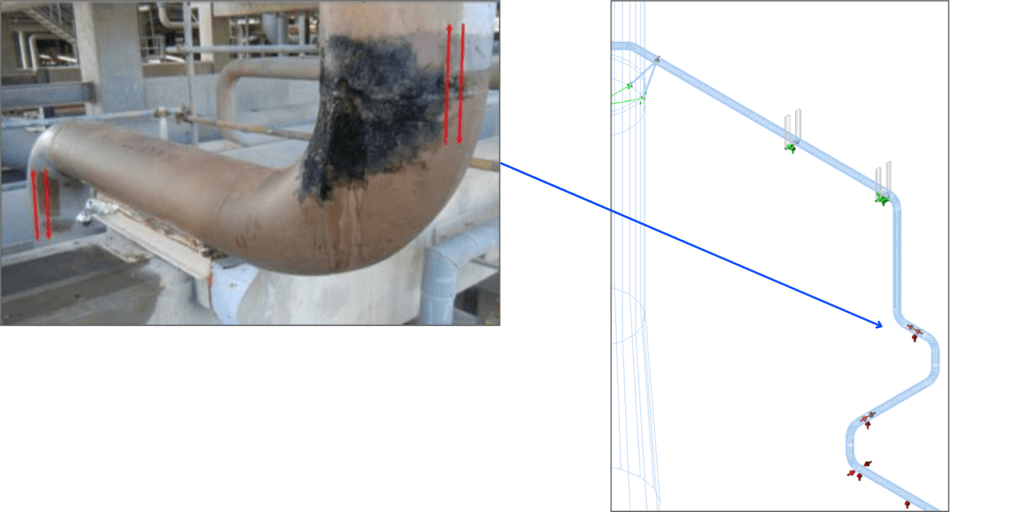

Failure in a Branch Connection: Natural Mode Analysis

A branch connection failure in a high-pressure steam system was caused by inadequate lateral restraints, leading to dynamic vibrations. Static and dynamic analyses identified excessive stresses and vibration modes. Support modifications were recommended to mitigate future failures effectively.

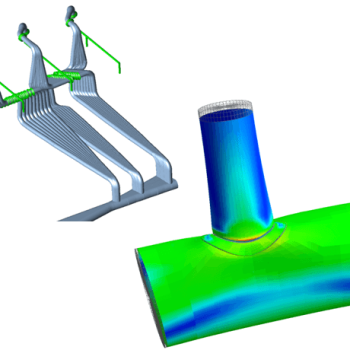

Assessment of Vibrating Process Line: Fatigue Analysis and Recommendations

Large process line vibrations caused by fluid density fluctuations damaged pipe supports, increasing fatigue risks. DRG recommended support repairs and axial stops to ensure system stability.

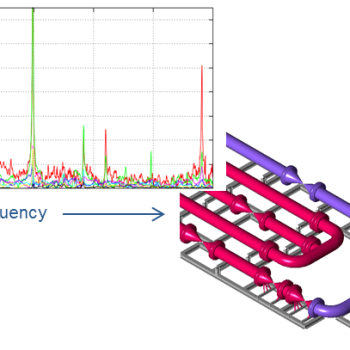

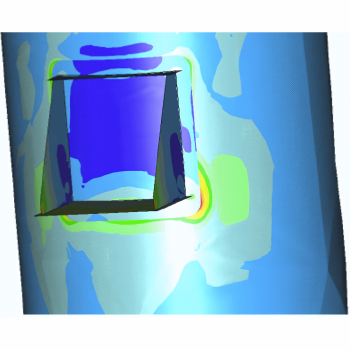

Noise and Vibration Analysis of a Metering Skid: An Acoustic and Mechanical Resonance Assessment

Dynaflow’s noise and vibration analysis of a gas metering skid identified potential fatigue risks from acoustic resonance and vortex shedding. Design recommendations ensured compliance and reliability.

Fatigue Analysis For A Reactor Feed Pressurization Drum

A fatigue analysis of a reactor feed pressurization drum confirmed stress levels below ASME VIII limits for 5+ million cycles, ensuring compliance and fatigue safety.

Fatigue Analysis of Interconnecting Lines between Norit Vessels and Heat Exchangers

Fatigue analysis of interconnecting lines between Norit vessels and heat exchangers identified cracking risks. Replacing pipe-to-pipe tees with welded tees extended service life to 100+ years.

Floating Head Heat Exchanger Fatigue Analysis

A fatigue analysis of a repurposed floating head heat exchanger identified insufficient fatigue capacity in shell-side nozzles. Adjusted nozzle loads ensured compliance with RToD standards.