Performing Vibration Measurements: Pipe Stress Assessment

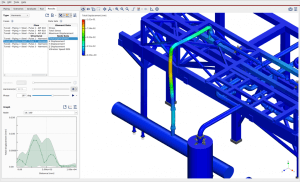

Training Courses Performing Vibration Measurements: Pipe Stress Assessment Download Brochure About The Course This course teaches you all the fundamentals required for performing vibration measurements