Performing Vibration Measurements: Pipe Stress Assessment

Training Courses Performing Vibration Measurements: Pipe Stress Assessment Free Course Preview Download Brochure About The Course This course teaches you all the fundamentals required for

Fiberglass Reinforced Plastic (FRP) piping, or Glass Reinforced Plastic (GRP) piping, offers a cost-effective alternative to corrosion-prone metallic and non-reinforced thermoplastic pipes. However, designing FRP systems requires specialized knowledge due to fundamental differences from steel piping design.

This course provides comprehensive training in the fundamentals of designing and working with FRP piping systems. It equips you with a solid understanding of material properties and behaviors alongside their impact on designs, covers the engineering process, including pipe stress analysis, and offers numerous real-life field examples to illustrate critical aspects of FRP systems.

The course is comprised of 8 online video modules, with 1-year unlimited access to the course materials and discussion forum for ongoing knowledge refreshment in support of your projects.

Welcome & Your instructors

Content Overview

How to use this course

Questions Forum

FRP Materials and manufacturing

Material specifications of FRP

Manufacturing methods of GRP

GRP Application

Material limitations

Market range

Applications of GRP

A sample of the first module is available for free, so you can learn more about the teaching style and understand if the course fits your needs.

FRP Material properties

Bi-axial materials

Steel versus FRP

Short-term and long-term strenght

Qualification

GRP qualification tests

GRP codes

Overview of GRP codes

Philosophies in GRP standards

Piping code ISO 14692

Stress analysis of FRP systems

Pipe stress analysis

Constructing a stress envelope

Reducing material stress

Surge analysis and flange assessment

Surge analysis for FRP piping

Flange assessment

Buried FRP Piping

Pipe stress analysis

Ring strenght calculations

Material failure theories

GRP material strength

Failure criteria

Ultimate Elastic Wall Stress

Material qualification

Full qualification

Regression

1000 hrs survival test

FRP failure

Longitudinal vs. circumferential cracks

Joint strength and failure in FRP

Joint strength and failure

Flange failure

Failure due to design errors

Failure miscellaneous

Introduction to Fiberglass engineering

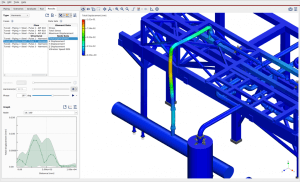

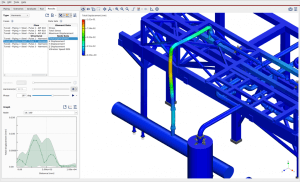

Introduction to Modeling Session

Agenda to Fiberglass engineering

Configuration editor in Caesar II

Special execution Parameters

Pipe vendor Engineering Guide Data

Material Properties Input

Pipe vendor Engineering Guide Proces

Pipe Stiffness Parameter Input

Stress Envelope Parameter Input

Pipe vendor input Hydrostatic Design Stress

Long-term Axial and Hoop Strength input

Modeling of Fittings

Pipe Support Span

Load case Set-up in ISO 14692

Interpretation of Results

Flange Check in Caesar II

Euler buckling for Aboveground Pipes

Shell Buckling

Course evaluation survey

Your Personal Certificate

Related resources

Self-Paced

This course is self-paced and is not subject to specific dates. The course contains 8 modules with a total of 9.5 hours of content which can be performed at your own pace. A personal certificate will be provided to you if you finish the course within the first month after purchase. This incentive aims to motivate you to perform the course on time, thereby improving your learning curve.

E-Hybrid

This course is privately scheduled for teams of a minimum of 4 people. A drip feed of modules becomes available to the participants throughout the program. The drip schedule aims to provide consistency to your learning experience and is designed to maintain participant concentration and provide adequate time to perform exercises between live instructor sessions where the instructor may answer any questions about the topic.

This course type is also available for a private schedule for teams of a minimum of 4 people.

Spring Program:

Classroom

This course is scheduled over 3 work days.

This course is available in self-paced, hybrid, and classroom formats.

Prerequisites and level

Intended For

This course is designed for:

Access to the self-paced course

After your purchase is confirmed you receive an account to the EngineeringTrainer online learning portal, where you can find the course in your dashboard. After opening the course you will be guided step-by-step through the different modules. You receive 1-year unlimited access to the course, allowing for the repetition of modules as desired.

Learn by doing

The self-paced and E-hybrid courses are mainly based on video content: video lectures and video software demonstrations. English subtitles are available and videos can be viewed as many times as desired. The video lectures help you to grasp the important technical concepts and in the video demonstrations the instructor uses the software and discusses all the steps and actions. You are recommended to follow the steps of the instructor in the software to optimize your learning curve.

The classroom course is performed in person either on-site or in the Dynaflow Research Group office located in Rijswijk, The Netherlands. This course enables you to be face-to-face with the instructors with live examples provided. This course also provides all participants with a 1-year access to the self-paced course.

Exercises & software models associated with the content are available for download.

Participants of the self-paced and E-hybrid courses receive a personal digital certificate if they meet the following requirements:

Participants of the classroom course receive a personal physical certificate upon the completion of the course.

Example certificate:

After this course, participants are expected to:

Video lectures

Video demonstrations

Discussions forum with other participants & instructor

The majority of training material are videos. These are not available for download, but can be accessed directly with your account on the portal.

You receive 1-year unlimited access to the course. This allows you to perform modules again when you need to refresh knowledge for your work projects.

We encourage participants to submit feedback and questions in the Discussions Forum of the course. These are either answered directly in the forum or form the basis for new videos that are added to the online course on a regular basis.

Participants receive 1-year unlimited access to the course including new videos that are added during this year. Participants receive an email notification upon addition of new course videos.

No technical software is used in this course.

If your computer and internet connection is able to play videos online (YouTube) you will be able to follow the course. Note that almost all browsers are supported, except for Internet Explorer.

Yes, this course qualifies for PDH hours as per the NCEES CPC Guidelines.

Training Courses Performing Vibration Measurements: Pipe Stress Assessment Free Course Preview Download Brochure About The Course This course teaches you all the fundamentals required for

Training Courses Piping: Structural Integrity About The Course Enhance your expertise in addressing technical challenges on a petrochemical plant. Join our introductory level ‘Piping Structural

Training Courses Pipe Stress Analysis Free Course Preview About The Course Pipe stress engineering is a broad area of expertise. To perform a pipe stress

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV