- Outline of latest info on the state of SIFs, k-factors, and SSIs.

- SIF/k/SSI changes and the impact on bends – and how they affect the pipe stress

- Collapse of straight pipe and desired changes

- Impact of pressure on SIFs and the contradictory results given by different solution methods in VIII-2 Part 5

- Optimizing Workflow and the pipe stress design process

- Allowable loads on pipe shoes – what affects allowable loads and how are they automatically reviewed

- API 661 header boxes, or rectangular constructions with nozzles attached.

- SIFs, k’s, SSIs, and allowable loads for all types of vessel connections.

- Multiple outputs and comparing results from any number of CAESAR model calculations.

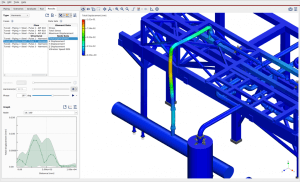

- Other Tools and Approaches (i.e. laser scanning, POD, AIV)

This course is scheduled over 2 work days. Course dates are organized upon inquiry.

This course is available in classroom formats.

Prerequisites and level

- Intermediate proficiency in the use of CAESAR II

- Level: Intermediate

Intended For

This course is designed for:

- Intermediate and advanced CAESAR II users

- Those looking for improved accuracy for critical systems

- Those wanting to stay on top of B31 code developments

- Owners of FEA Tools

- Those combining 3-D FEA with piping models

The classroom course is performed in person either on-site or in the Dynaflow Research Group office located in Rijswijk, The Netherlands. This course enables you to be face-to-face with the instructors with live examples provided. This course also provides all participants with a 1-year access to the self-paced course.

Exercises & software models associated with the content are available for download.

Participants of the classroom course receive a personal physical certificate upon the completion of the course.

Example certificate:

After this course, participants are expected to:

- Learn how to use the recently released FEATools software

- Staying on top of the latest developments in piping stress

- Gain a better understanding of the critical aspects of piping systems.

- Learn to see if an overstressed location is only a theoretical issue due to inaccurate SIFs and k’s

- Lots of examples and tutorials to gain proficiency