PV-Elite

Training Courses PV-Elite About The Course Whether you are designing a pressure vessel according to the ASME VIII, PD5500 or EN 13445, PV-Elite offers you

Cultivate expertise in the EN13445 design code, the essential standard for unfired pressure vessel design compliant with the Pressure Equipment Directive (2014/68/EU). In an era where automated software often obscures the calculation process, this course restores clarity by elucidating the foundational equations and principles that underpin these design rules.

Explore critical questions such as the area replacement rule, the application of the Taylor and Forge method, and the inner-stiffener distance required to prevent vacuum-induced collapse. Gain insights into distinguishing between primary and secondary stresses and their evaluation within the code.

This course extends beyond rote application, challenging participants to understand the rationale behind each rule’s formulation. Moreover, it highlights key distinctions compared to the ASME BPVC Section VIII Division 1 code.

Welcome to the course

Your instructors

Live session schedule

How to use this course & join the live sessions

Personal Certificate requirements

Introduction

Scope

Materials

Brittle failure & creep

Module 1, Exercise 1

Welds and discontinuities

Fatigue analysis

Wall thickness & corrosion

Hydrostatic test pressure

A sample of the first module is available for free, so you can learn more about the teaching style and understand if the course fits your needs.

Intro: Stress definitions

Stress/Strain relationships

Stress/Strain relationships

Load cases

Maximum design stress

Module 2, Exercise 1

Intro: Shell design

Cylindrical shells

Spherical shells

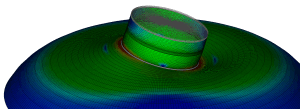

Formed ends

Cones and conical sections

Cone to cylinder transition

Module 3, Exercise 1

Intro: Shell design

Cylindrical shells

Cylinder with Stiffeners

Module 4, Exercise 1

Cones

Shell ends

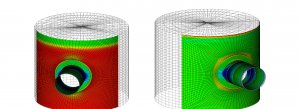

Intro: Vessel openings

Pressure area method

Analysis of a set-on nozzle

Adjacent openings

Special cases

Module 5, Exercise 1

Intro: Flat ends & flanges

Clause 10: Flat Ends

Flange types

Taylor-Forge flange check

Pressure rating method

Flange analysis

Module 6, Exercise 1

Intro design-by-analysis

What is design-by-analysis?

The equivalent stress

Module 7, Exercise 1

Stress Decomposition

Stress assessment

Stress decomposition

Instability & Buckling

Module 7, Exercise 2

Intro: Fatigue assessment

Simplified fatigue check

Detailed fatigue assessment

Fatigue safety factor

Comparing fatigue checks

Module 8, Exercise 1

Intro: Heat exchangers

Types of heat exchangers

Tubesheet thickness

Module 9, Exercise 1

Alternative methods

Bellows & expansion joints

Rectangular vessels

Applied forces & moments

Lifting lugs

Saddle supports

Supports

Congratulations

Course evaluation survey

Your Personal Certificate

Rate this course

Related resources

Follow up

Self-Paced

This course is self-paced and is not subject to specific dates. The course contains 9 modules with a total of 7 hours of content which can be performed at your own pace. A personal certificate will be provided to you if you finish the course within the first month after purchase. This incentive aims to motivate you to perform the course in a timely manner, thereby improving your learning curve.

E-Hybrid

This course is scheduled regularly with a drip feed of modules becoming available to the participants throughout the program. The drip schedule aims to provide consistency to your learning experience and is designed to maintain participant concentration and provide adequate time to perform exercises between live instructor sessions where the instructor may answer any questions about the topic.

The dates of the course are organized upon inquiry.

Classroom

This course is scheduled over a duration of 2 work days. The dates of the course are organized upon inquiry.

This course is available in self-paced, hybrid, and classroom formats.

Prerequisites and level

Intended For

This course is designed for:

Access to the course

After your purchase is confirmed you receive an account to the EngineeringTrainer online learning portal, where you find the course in your dashboard. After opening the course you will be guided step-by-step through the different modules. You receive 1-year unlimited access to the course. This allows you to perform modules again if this is beneficial for your work projects.

Learn by doing

The course is mainly based on video content: video lectures and video software demonstrations. English subtitles is available and videos can be viewed as many times as desired. The video lectures help you to grasp the important technical concepts and in the video demonstrations the instructor uses the software and discusses all the steps and actions. You are recommended to follow the steps of the instructor in the software to optimize your learning curve.

Exercises are available in the form of multiple choice quizzes to help you grasp technical concepts and in the form of .pdf-files with instructions to build and analyze different models and answer related questions. Video demonstrations of the exercises are available.

Participants of the self-paced and E-hybrid courses receive a personal digital certificate if they meet the following requirements:

Participants of the classroom course receive a personal physical certificate upon the completion of the course.

Example certificate:

After this course, participants are expected to:

Video lectures

Video demonstrations

PDF exercises

Exercise answers by demonstrations (video)

Multiple choice questions that help understand technical concepts

The majority of training material are videos. These are not available for download, but can be accessed directly with your account on the portal. Apart from quizzes the exercise files can be downloaded. These can include .pdf files with the exercise questions, software models or other file types. You receive 1-year unlimited access to the course. This allows you to watch content again if this is beneficial for your work projects.

We encourage participants to submit feedback and questions. These form the basis for new, future videos that will be added to the online course, but they will not be answered to the student directly.

Participants receive 1-year unlimited access to the course including new videos that are added during this year. Participants receive an email notification upon addition of new course videos.

No software is used for this course or will be distributed.

Yes, this course qualifies for PDH hours as per the NCEES CPC Guidelines.

Training Courses PV-Elite About The Course Whether you are designing a pressure vessel according to the ASME VIII, PD5500 or EN 13445, PV-Elite offers you

Training Courses NozzlePRO Essentials Free Course Preview Download Brochure About The Course This self-paced course teaches you all the fundamentals, and much more, about working

Training Courses FEPipe Essentials Free Course Preview Download Brochure About The Course Enhance your proficiency with FEPipe software through a comprehensive training program. Suitable for

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV