PV-Elite

Training Courses PV-Elite About The Course Whether you are designing a pressure vessel according to the ASME VIII, PD5500 or EN 13445, PV-Elite offers you

The ASME VIII-1 design code is the most widely used design code for pressure vessel design. Often the rules are applied using automated software packages such as Compress or PVElite and the engineer can lose the overview of the calculation being performed. This course aims to explain the fundamental equations and principles in the design by rules approach. For example: What is the area replacement rule? How is the Taylor and Forge method applied for flanges? What is the minimum ligament length between nozzles and why? What inter-stiffener distance is required to prevent collapse under vacuum?

Topics include many design features such as design of shells and heads under internal and external pressure, nozzles & openings, flange connections, heat exchanger, tubesheets, saddles and skirts.

As well as explaining the rules and how to apply them, you will be challenged on why a rule is formulated in a particular way.

The course consists of 8 online self-study modules. All training content is provided through your EngineeringTrainer account. This course is also available for E-hybrid and classroom based learning on request.

After the course you maintain 1-year unlimited access to the course and the discussions forum. This allows you to perform modules again when you need to refresh the knowledge for your projects.

Welcome to the course

Your instructors

How to use this course

Introduction and Agenda

ASME VIII-1 Code Coverage: Outline and Build-up

Materials Aspects and Codes

ASME Section 2 part D: Material Tables

Weld Joint Efficiency in ASME Section 8, division 1

Non Destructibe Testing related to Joint Efficiency Factor

Design Loads – Part 1, 2 & 3

U-stamping for Pressure Vessels

Code Design Stresses and Allowables

Fatique Design in ASME VIII-1

Brittle Fracture: Physical Concepts

Analyzing Brittle Fracture as per the ASME BPVC VIII-1

Module 1, Excercises 1: Weld Joint Efficiencies

Module 1, Excercise 2: Determining the MDMT

A sample of the first module is available for free, so you can learn more about the teaching style and understand if the course fits your needs

Stress-Strain Relationships and Concepts

Material Stresses for Cylindrical Shells

Load Cases and Failure Modes

Maximum Allowable Values for the Design Stress

Introduction and Agenda

Cylindrical Shells under Internal Pressure

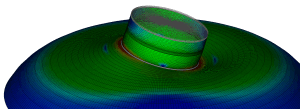

Spherical Shells and Formed Ends

Cones and Conical Sections under Internal Pressure

Introduction and Agenda

Introduction to Buckling for Pressure Vessels

Buckling Examples and Illustrations

Axial Compression Loads as per ASME VIII-1

Compressive Stress: Allowable Value

Cylindrical Shells under External Pressure

Thin Walled Shells: Buckling Evaluation

Buckling Critical Length as per ASME VIII-1

Thick walled Shells: Buckling Evaluation

What are Stiffener Rings?

Using Stiffener Rings as per ASME VIII-1

Vessel Heads under External Pressure – Part 1 & 2

Introduction and Agenda

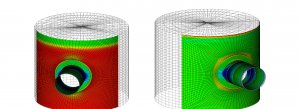

Shell Openings: An Introduction

Area Replacement Rule as per ASME VIII-1

Area Replacement Rule: Step 1, 2, 3 & 4

Ligament Efficiency Rules as per ASME VIII-1

Ligament Efficiency Rules: Diagonal Lines

Introduction and Agenda

Flat Plates, Covers, Flanges and Design Rules in ASME VIII-1

Bolted Connections as per ASME VIII-1

Gasket Selection for Flanges

Bolt Evaluations for Flanges

Design of Bolted Flanges and Associated Calculations

Calculation Steps for Bolted Connections – Part 1 & 2

Equivalent Pressure Rule for Flange Evaluation

Introduction and Agenda

Types of Heat Exchangers and Analysis Methods

Tubesheet Properties: Calculating Effective Values

Tubesheet Thickness and Related Calculations

Alternative Methodes for Tubesheet Design

Rectangular Vessels as per ASME VIII-1

Openings in Non-Circular Vessels

Half-Pipe Jackets as per ASME VIII-1

Congratulations

Course evaluation survey

Your Personal Certificate

Rate this course

Related resources & follow up

Self-Paced

This course is self-paced and is not subject to specific dates. The course contains 8 modules with a total of 6.5 hours of content which can be performed at your own pace. A personal certificate will be provided to you if you finish the course within the first month after purchase. This incentive aims to motivate you to perform the course in a timely manner, thereby improving your learning curve.

E-Hybrid & Classroom

This course is also available in E-Hybrid and classroom type formats on request.

This course is available in self-paced, hybrid, and classroom formats. The course is available for all

Prerequisites and level

Technical background

Level: Intermediate

Intended For

This course is designed for:

After your purchase is confirmed you receive an account to the EngineeringTrainer online learning portal, where you can find the course in your dashboard. After opening the course you will be guided step-by-step through the different modules. You receive 1-year unlimited access to the course, allowing for the repetition of modules as desired.

Learn by doing

The course is mainly based on video content: video lectures and video software demonstrations. English subtitles is available and videos can be viewed as many times as desired. The video lectures help you to grasp the important technical concepts and in the video demonstrations the instructor uses the software and discusses all the steps and actions. You are recommended to follow the steps of the instructor in the software to optimize your learning curve.

Exercises are available in the form of multiple choice quizzes to help you grasp technical concepts and in the form of .pdf-files with instructions to build and analyze different models and answer related questions. Video demonstrations of the exercises are available.

Participants of the course receive a personal digital certificate if they meet the following requirements:

Example certificate:

After this course, participants are expected to:

Video lectures,

Calculation exercises,

Instructor-led live sessions with lectures, group discussions, exercises and Q&A’s,

Discussion forum with other participants & instructor.

Exercise files can be downloaded, these can include .pdf files with the exercise questions or other file types. Videos will not be available for download, but can be accessed directly with your account on the portal. If slides are used in the videos or live sessions these can be viewed separately as well through the portal, but are not available for download.

You receive 12-months unlimited access to the course. This allows you to watch content again if this is beneficial for your work projects.

Yes, live sessions are included in this course that allow you to interact with the instructor and ask questions. Additionally, questions can be submitted in the learning portal by the participants which are addressed in the live sessions.

No software is required for participants of this course.

Self-paced Modules

If your computer and internet connection are able to play videos online and have MS Teams calls you will be able to follow the course. Note that almost all browsers are supported, except for Internet Explorer.

Live sessions

Live events are provided by means of Microsoft Teams. Hence it required to have an MS Teams account. Additionally, a webcam and microphone are mandatory for the live events. Separate earplugs are recommended as to avoid sound echo.

Yes, this course qualifies for PDH hours as per the NCEES CPC Guidelines.

Training Courses PV-Elite About The Course Whether you are designing a pressure vessel according to the ASME VIII, PD5500 or EN 13445, PV-Elite offers you

Training Courses NozzlePRO Essentials Free Course Preview Download Brochure About The Course This self-paced course teaches you all the fundamentals, and much more, about working

Training Courses FEPipe Essentials Free Course Preview Download Brochure About The Course Enhance your proficiency with FEPipe software through a comprehensive training program. Suitable for

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV