Mitigating Pressure Surge Impact In A Process Line At BASF Antwerp

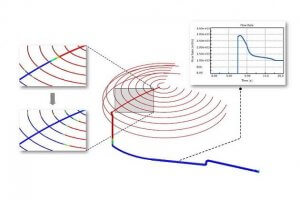

Pressure surges ocurr in piping systems whenever there are sudden changes in flow resistance from steady operation. Surges can cause significant damage, also at locations

Pressure surges ocurr in piping systems whenever there are sudden changes in flow resistance from steady operation. Surges can cause significant damage, also at locations

Hydrogen generation equipment has an inherent risk for internal explosions, posing an issue to safety. The hydrogen piping and equipment are required to withstand internal

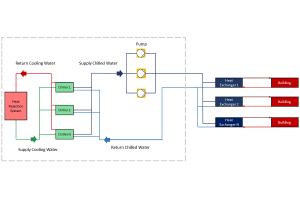

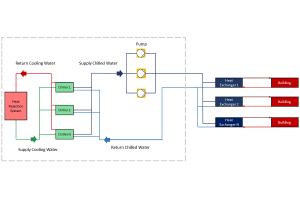

A District Cooling System (DCS) fits the sustainability challenges that our society is challenged with. It provides cooling capacity from a central facility; chilled water

Shell is building a biofuels facility at the Shell Energy and Chemicals Park Rotterdam, the Netherlands (Pernis Refinery) that will have an annual production capacity

Why Pay Attention to a Line Filling Process? During a start-up/line filling process a wave front of fluid progresses it’s way through the empty* parts

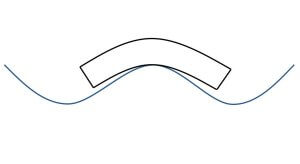

What is Hogging and Sagging and what are the effects on piping? When waves pass over the length of a ship, the ships profile rises

Shell is building a biofuels facility at the Shell Energy and Chemicals Park Rotterdam, the Netherlands (Pernis Refinery) that will have an annual production capacity

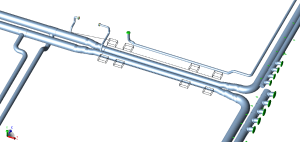

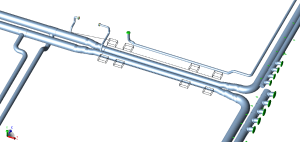

Dynaflow Research Group provided consultancy services to finalize the construction of cooling water (CW) system of a chemical plant in the Texas, USA. The construction

Combined Pressure Surge and Dynamic Stress Analysis Introduction In the harbor of Antwerp an unloading line was being commissioned for use with cyclohexane. This line

Pressure Surge Analysis Introduction An LNG-plant was planning to construct an additional LNG bunkering line that will be used to fuel ferry ships in Stavanger.

A District Cooling System (DCS) fits the sustainability challenges that our society is challenged with. It provides cooling capacity from a central facility; chilled water

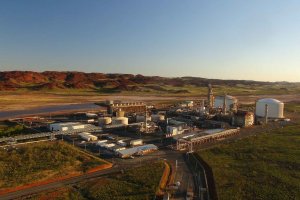

For an ammonia plant in Western Australia, cooling water is supplied by a Sea Cooling water (SCW) as well as a Fresh Cooling Water (FCW)

Dynaflow Research Group has performed a root-cause analysis for a cooling water system that had 3 recent leakages. The failures were in 10” pipe and

Dynaflow Research Group provided consultancy services to finalize the construction of cooling water (CW) system of a chemical plant in the Texas, USA. The construction

Pressure Surge Analysis Introduction An existing power plant of Essent will be extended with a new power plant. The new power plant is based on

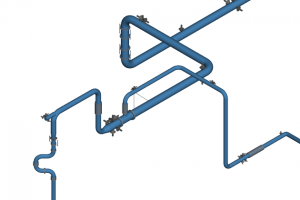

Feasibility Study Introduction A cooling water system consists of a large underground branched GRP piping system connecting to steel branch continuations at each U/G-A/G interface.

Shell is building a biofuels facility at the Shell Energy and Chemicals Park Rotterdam, the Netherlands (Pernis Refinery) that will have an annual production capacity

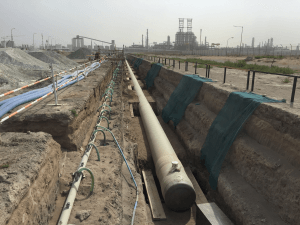

Air Liquide and BASF want to capture and store the CO2 of five factories at the BASF site in Antwerp. Dynaflow was requested to perform

The geothermal installation Trias Westaland, with presently 2 geothermal doublets, produces 40MW of sustainable thermal energy that is supplying heat to 54 greenhouses and several

What is Hogging and Sagging and what are the effects on piping? When waves pass over the length of a ship, the ships profile rises

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV