Pipe Stress Analysis - Case Studies

Seawater Supply Header: Static Stress Analysis

The above-ground seawater supply header is designed to transport seawater from two tie-ins in a discharge manifold of the seawater pumps to AGA. A comprehensive static stress analysis was necessary to determine the stress levels within the Glass Reinforced Epoxy (GRE) line.

Verification of a Continuous Steam Generation System (SGS): Static Stress Assessment

This case study explores the static stress assessment of a continuous steam generation system (SGS) using finite element method analysis. The focus is on a small-diameter plant that utilizes molten salt to generate steam in a heat exchanger at a solar plant facility.

Sulphur Recovery Burners Assessment: Stress Analysis

DRG was engaged to conduct a stress analysis for two sulphur recovery burners, adhering to ASME VIII Division 1 Boiler and Pressure Vessel Code. This analysis involved traditional Division 1 calculations complemented by Finite Element Analysis (FEA) to evaluate the impact of nozzle loads on critical junctions.

Design Verification of a Thermal Energy Storage System (TESS): Static and Fatigue Assessment

A comprehensive finite element method (FEM) analysis was conducted on a molten salt/oil heat exchanger used in a solar plant facility. This heat exchanger is one of three identical units connected in series, operating under high pressures and temperatures with significant pressure and temperature cycling throughout day and night.

Stress Analysis of LNG Bunkering Line: Dynamic and Static Evaluations

This project involves the installation of new piping, which will be completed in multiple phases. This case study focuses on evaluating the material stresses, as well as the loads on restraints, nozzles, and flanges, in accordance with the relevant engineering codes.

Fatigue Analysis of Interconnecting Lines between Norit Vessels and Heat Exchangers

Since the early 1980s, cracks have been observed in the off-gas cleaning section of the ethylbenzene hydroperoxide (EBHP) reaction unit. To address environmental concerns, EBHP must be removed from the off-gas before flaring.

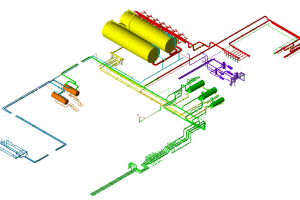

Pipe Stress Analysis for an Oil and Gas Extraction Facility

Dynaflow Research Group (DRG) conducted comprehensive pipe stress analyses for a large oil and gas extraction facility. This facility comprises three onshore flow stations, one offshore flow station, and a gas export compressor station.

Main Burner Stress Analysis Case Study

This case study examines a stress analysis conducted in accordance with ASME VIII Division 1 Boiler and Pressure Vessel Code for a main burner system. The burner in question features a vessel with an air inlet nozzle and connects to a “gun” with both a fuel gas inlet and an acid gas inlet.

Assessment of Vibrating Process Line: Fatigue Analysis and Recommendations

Large amplitude vibrations in a process line have resulted in damage to several pipe supports. DRG was engaged to identify the root cause of these vibrations, assess potential fatigue issues, and recommend remedial actions for the client

Double Burner-Chamber Assembly Stress Analysis

A comprehensive stress analysis was conducted on an assembly comprising two burners and two interconnected chambers. Each burner generates a substantial flame, which combusts waste gas within the chambers.

On-Skid and Off-Skid Air Combustion Lines Design

The combustion air system of an incinerator is a crucial component for its operation, consisting of a fan, two skids, interconnecting piping, and the incinerator itself. Dynaflow Research Group (DRG) was tasked with designing both the on-skid and off-skid piping systems, including those connecting the air fan and the incinerator.

GRE Firewater System for a Sea Jetty Under Seismic and Wave Loadings: Stress Analysis

During the design phase of a sea jetty for an oil terminal, Dynaflow Research Group (DRG) conducted a comprehensive stress analysis for the glass reinforced epoxy (GRE) firewater system.