Assessment of a Jetty Pipeline: Combined Pressure Surge and Dynamic Stress Analysis

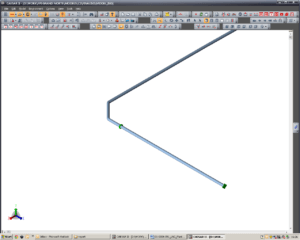

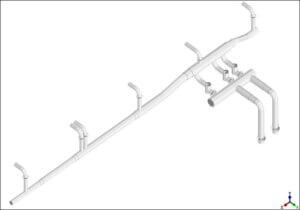

A steel pipeline was under construction for offloading naphtha from ships arriving at a jetty. A surge analysis was conducted to evaluate the pipeline’s capability

A steel pipeline was under construction for offloading naphtha from ships arriving at a jetty. A surge analysis was conducted to evaluate the pipeline’s capability

DRG was engaged to conduct a comprehensive stress analysis for three sulphur recovery burners, in accordance with ASME VIII Division 1 of the Boiler and

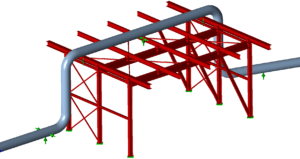

A comprehensive stress and surge analysis was performed for the firewater piping system of an LNG plant located in South America. The system, constructed using

The customer needed to determine the flow split between six cooling towers within a cooling tower arrangement. Analysis The six cooling towers were fed from

This project presented the assessment results of the analysis of the pressure-containing part of an actuator. The focus was on evaluating the actuator’s integrity through

In this study, the details and results of the stress analysis performed for the design of two platforms attached to the reinforcement rings of a

This case study detailed the static and dynamic assessment of a Wintrack Tower. Wintrack Towers represented a new geometrical design for suspension towers for high-tension

Dynaflow Research Group conducted a comprehensive stress analysis on three critical components of a high-pressure heat exchanger: the stationary tubesheet, cone-shaped channel, and shell with

On-Demand Webinar Acoustic Induced Vibrations (AIV) and Flow-Induced Vibrations (FIV) are critical phenomena that can lead to significant operational challenges and even catastrophic failures in

Typical scope of work and activities Phase 0 – Initial recommendations Phase 1 – Modelling of the system and identifying all operating conditions Phase 2a:

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV