Oil & Gas

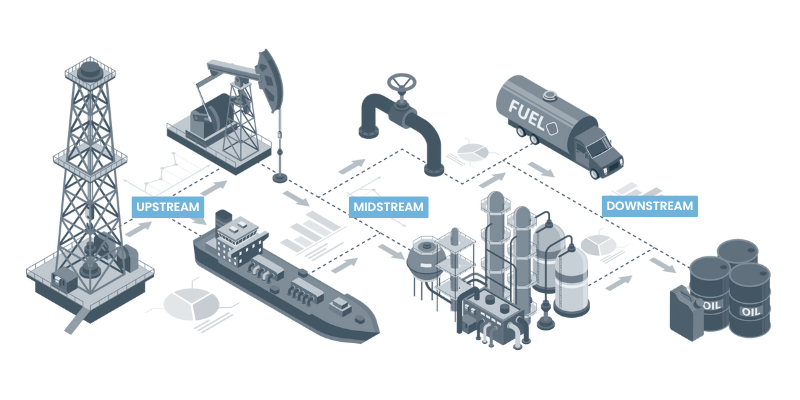

The Oil and Gas industry faces substantial challenges across Upstream, Midstream, and Downstream segments. Complex fluid behaviors, multiphase flow issues, pressure surges, pulsation-induced vibrations, structural fatigue, and equipment failures significantly impact performance, safety, environmental compliance, and profitability.

Dynaflow provides specialized engineering analysis services to directly address these challenges. These services deliver critical insights, optimize operations, enhance asset reliability, and improve safety standards, helping clients mitigate risks, maintain compliance, and maximize operational efficiency.

OIL & GAS SOLUTIONS

Upstream Services

Efficient and safe extraction requires careful management of complex fluid behaviors, multiphase flows, and maintaining flow assurance in harsh environments.

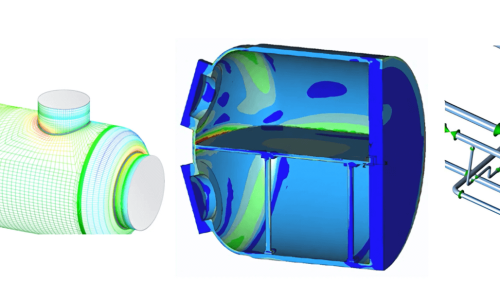

In upstream operations, managing multiphase flows and ensuring flow assurance are critical. Dynaflow’s CFD capabilities enable accurate modeling of complex fluid behaviors in production systems, separators, and offshore equipment. Our expertise helps operators optimize fluid handling, prevent slugging, and mitigate erosion risks, ensuring stable and efficient production.

Dynaflow specializes in analyzing multiphase flow phenomena, addressing challenges such as slugging, hydrate formation, and erosion. Using industry-standard software such as BOSfluids, we help operators maintain steady production, reduce downtime, and enhance equipment reliability.

Dynaflow provides comprehensive flow assurance analysis to predict and mitigate hydrodynamic risks such as severe slugging, pressure surges, and transient multiphase flow effects. Our advanced simulations help operators maintain steady, safe, and efficient production, minimizing operational disruptions and maximizing system reliability.

Midstream Services

Midstream operators must ensure efficient, safe, and reliable transport and storage of oil and gas products, minimizing the risks associated with pipeline integrity, leaks, corrosion, pressure surges, and storage tank stability.

We improve pipeline efficiency by analyzing and optimizing fluid flow patterns, reducing operational costs and enhancing throughput. Dynaflow’s CFD studies identify bottlenecks, pressure drops, and inefficiencies, providing actionable solutions.

Pressure surges pose significant risks to pipeline integrity. Dynaflow’s surge and waterhammer analysis identifies critical points and recommends effective surge protection measures, safeguarding pipelines and reducing operational risks.

Dynaflow conducts pulsation studies to analyze and mitigate harmful pressure oscillations in pipeline systems and reciprocating equipment. Our solutions reduce vibration-induced fatigue, extend equipment life, and enhance operational reliability.

Dynaflow evaluates erosion and corrosion phenomena in pipelines and equipment, providing predictive insights to prevent failures and optimize maintenance scheduling, prolonging asset lifespan.

Downstream Services

Downstream operations must optimize refining processes, manage heat exchange efficiency, ensure proper mixing and separation procedures, and control vibrations and environmental emissions to maximize productivity and safety.

Dynaflow applies CFD to optimize downstream processes, improving efficiency in refining and chemical processing units. Our simulations identify bottlenecks, enhance throughput, and reduce energy consumption.

Dynaflow’s CFD expertise optimizes heat exchanger performance, identifying flow distribution issues and improving thermal efficiency. This reduces energy consumption and operational costs in refining facilities.

Effective mixing and separation are critical for product quality. Dynaflow’s CFD analysis ensures optimal mixing and separation performance, reducing processing time and enhancing product purity.

Dynaflow identifies and mitigates vibration-induced fatigue in downstream equipment, such as pumps, compressors, and piping systems. Our vibration analysis services prevent equipment failures, reduce maintenance costs, and enhance operational reliability.

PROJECTS, ARTICLES & WEBINARS

Oil & Gas Insights

Innovative Modeling Techniques for Simulating Pipeline Systems: A Deep Dive into Firewater System Simulations