Introduction

A serious crack next to a weld in the circulating water flow system was found but it was unclear what had caused this crack. The objective of this case was to find the mechanism, or events, that may have caused the crack in the system and to find a possible solution to prevent other cracks from occurring in the future.

Analysis

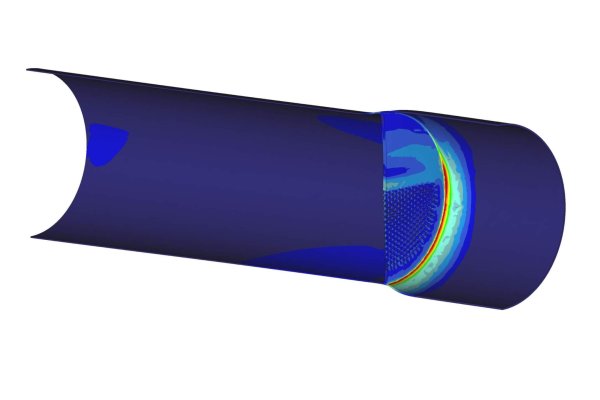

Various events and mechanisms have been analyzed. The mechanism closest to a full explanation is the recirculation water pump trip resulting in unbalanced loads in the piping. The resulting movements and inertia of the piping have introduced an alternating stress of a high enough level for LCF (low cycle fatigue) to occur, eventually resulting in a failure next to the weld.

Results

The mechanical response analysis shows that 200-300 pump-trips are required for the weld to fail due to low cycle fatigue. This amount of pump trips may have occurred during the year. On the other hand, detailed metallurgical investigation of the crack did not unambiguously indicate low cycle fatigue as the obvious failure mechanism. However, the same investigation did not reject low-cycle fatigue as a possible mechanism.

“What caused the crack next to a weld in the circulating water flow system?”

The analysis concluded that a series of pump trips over time is the most likely source of the failure. All other possible causes have been investigated and all of them have a much lower impact and are much less likely to be the source of the crack.