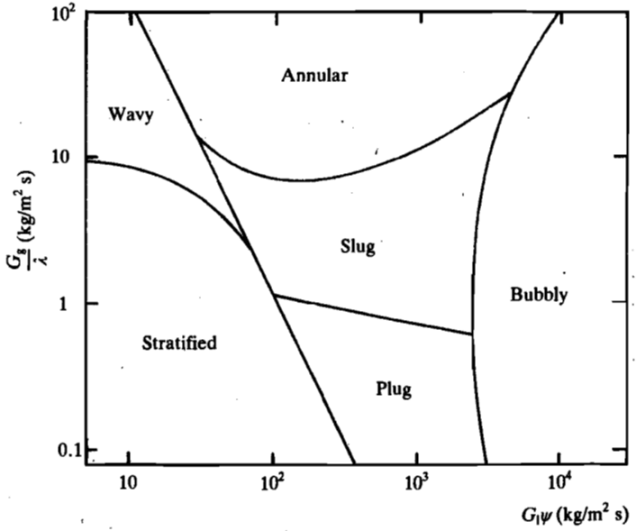

A fuel jetty terminal operator expressed concerns about potential two-phase flow issues during off-loading operations. The client indicated that trapped nitrogen used for purging lines could mix with the liquid being off-loaded when empty ship tanks were flushed with inert nitrogen.

This scenario raised the possibility of slug flow development, which could generate fluctuating impulses at reaction surfaces. The magnitude of these unbalanced forces depended heavily on liquid velocity and specific weight.

Additionally, the client questioned the adequacy of installed directional stops, which utilized DIN3567 clamps. These clamps were thinner and narrower than their British Standard counterparts for equivalent pipe sizes, prompting concerns about their load-bearing capacity.

Analysis

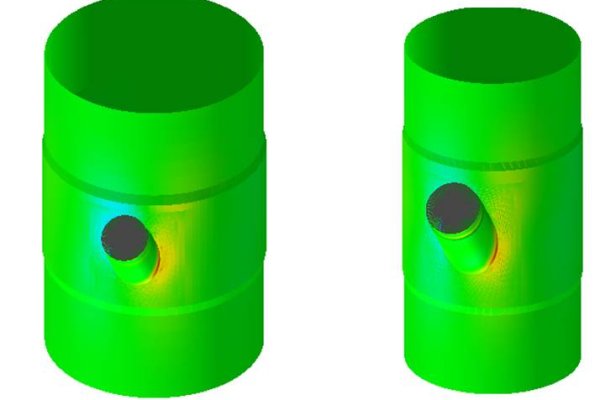

Engineers conducted a comprehensive study to assess the likelihood of slug formation in the loading and unloading piping systems. Their findings confirmed the potential for slug formation under the conditions described by the client. Subsequently, they calculated the impact of these slugs in terms of unbalanced forces.

The analysis revealed that the unbalanced forces resulting from slug flow were relatively low. Importantly, the calculated loads fell within the capability of the supports installed on-site, alleviating some of the client’s initial concerns.

Results

The study yielded several key conclusions regarding slug flow and support capability:

- Slug Formation: The analysis confirmed that slug formation could occur during piping operations. While the calculated slug loads were mild compared to the axial stops’ capabilities, engineers strongly advised conducting a surge analysis to account for other potential dynamic effects that could cause excessive loads.

- Support Capability: Previous calculations performed on equivalent supports using DIN pipe clamps produced an allowable load table identical to the one provided by the client. This finding indicated no reason to derate the axial stops’ capability.

Key Takeaways

- Two-phase flow analysis is crucial for assessing potential operational risks in fuel jetty terminals.

- Slug flow can occur when trapped nitrogen mixes with off-loaded liquid, but its impact may be less severe than initially feared.

- DIN3567 clamps, despite being thinner and narrower, demonstrated adequate load-bearing capacity for the application.

- Surge analysis is recommended to account for additional dynamic effects beyond slug flow.

- Thorough engineering analysis can often alleviate client concerns based on incomplete on-site observations.

This case study highlights the importance of rigorous engineering analysis in addressing operational concerns in complex fluid handling systems. By combining theoretical modeling with practical considerations, engineers can provide valuable insights to optimize system performance and safety.