Introduction

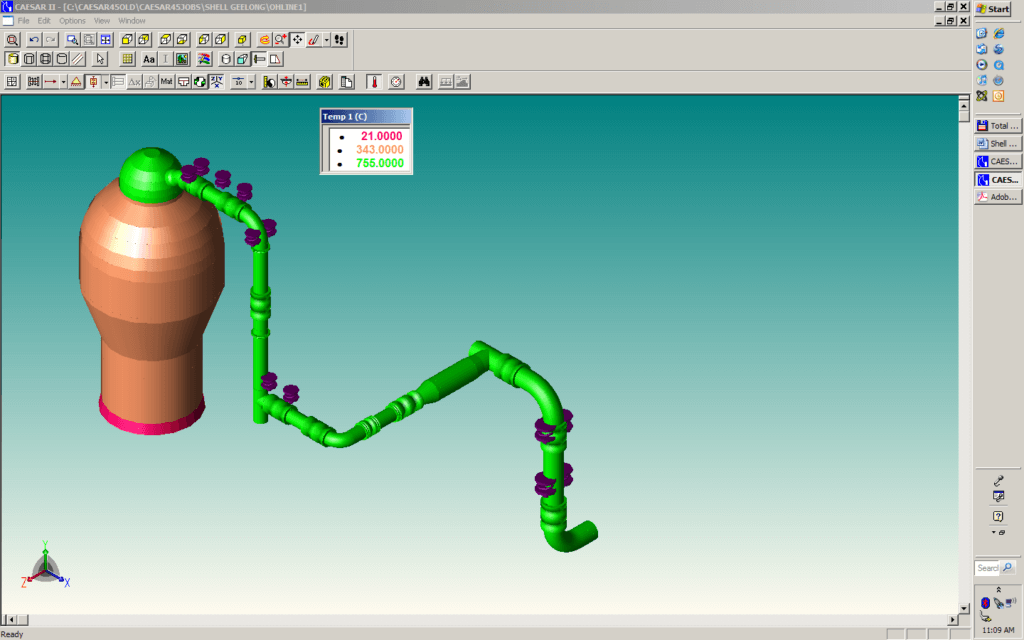

In this case study, we delved into the stress analysis findings regarding the revised flue gas overhead line in Singapore connecting a third-stage separator to a waste heat boiler. This line operates at high temperatures, leading to a relatively low allowable material stress. Additionally, due to the thermal expansion of the system line and the thermal growth of the separator, adequate pipe flexibility is crucial.

Analysis

The analysis was conducted based on the layout and support arrangement provided in the isometrics supplied by the client. The overhead line between the separator and the boiler was divided into two sections for analysis: one upstream and one downstream of the boiler. A “modified” layout was employed, involving a truncated arrangement where the flow through the expander was obstructed by the introduction of blind flanges or end caps, effectively disconnecting the duct from the expander. Various iterations were undertaken to analyze and configure the support arrangement (spring arrangement) for the section downstream of the separator.

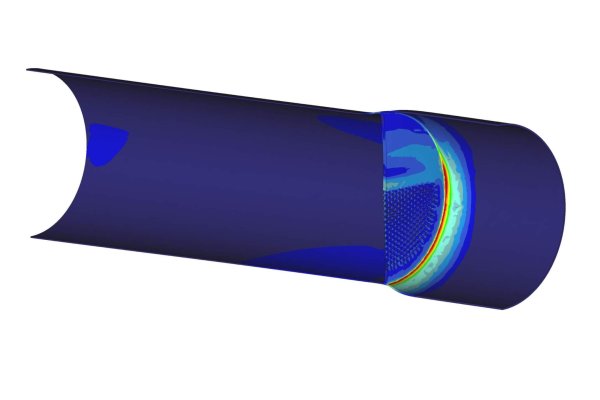

Expansion joints, comprising six Gimbal-type joints and three hinged-type joints, were utilized to introduce an additional 15 degrees of freedom in the section downstream of the TSS. The deflections of these expansion joints were evaluated, with their stiffnesses and weights obtained from relevant supplier drawings.

Results

The analysis results confirmed the adequacy of the support arrangement for the flue gas overhead line between the separator and waste heat boiler. The identified support arrangements ensure the structural integrity of the duct system for at least 20 years of sustained operation under working conditions.

“Using expansion joints, 15 additional degrees of freedom were introduced in the section downstream of the TSS”

Notably, the study did not assess waste heat boiler nozzle loads. The arrangement featuring an anchor immediately upstream of the waste heat boiler nozzle consistently yielded artificially high nozzle loads. Despite this, the arrangement remained unchanged and has demonstrated suitability for operation in the past.