Introduction

In this case study, we examine the static stress analysis performed on eight metering skids designed for a flow station. These skids, intended for either gas or liquid flows, varied in diameter from 6 to 32 inches. DRG was commissioned to carry out a comprehensive static stress analysis encompassing both the process piping and the supporting structural steel frame.

Analysis

The stress analysis was conducted using CAESAR II pipe stress software. DRG developed CAESAR II models that included both the piping and the structural steel framework of the metering skids. The analysis adhered to the ASME B31.3 design code for process piping. However, CAESAR II does not support code compliance checks for structural assemblies, prompting DRG to develop an in-house software routine for evaluating the structural steel frame.

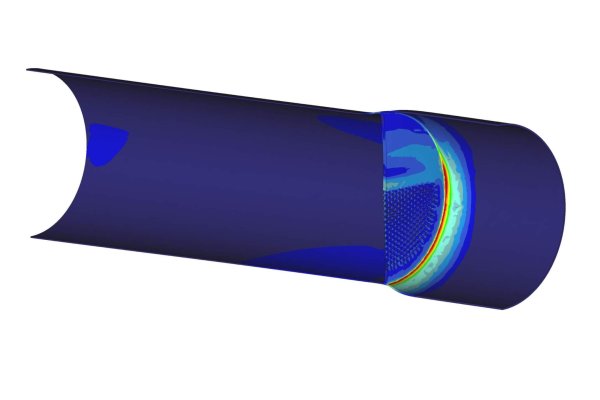

Additionally, a code compliance check for the pipe saddles in two of the skids was necessary. DRG employed Finite Element Methods (FEM) for this purpose, utilizing the FEPipe software package to ensure accuracy.

Results

The analysis revealed that while most of the metering skid designs met the design code requirements, several critical issues were identified.

One significant issue was related to the differing rates of thermal expansion within the piping of one metering skid, resulting in non-compliance with the B31.3 design code. Given the client’s requirement for the metering skid to be compact and fit within a specific floor space, DRG collaborated closely with the client to redesign the skid. This redesign ensured code compliance while maintaining the required compact footprint.

In addition, several structural beams within the frames were found to be overstressed, primarily due to their inadequate torsional resistance. To address these issues, DRG recommended modifications to the structural steel frame to eliminate the regions where large torsional moments were generated.

Conclusion

The static stress analysis conducted by DRG highlighted critical areas in both the process piping and the structural steel frame of the metering skids. By addressing these issues through redesign and modification, DRG ensured that the skids complied with the relevant design codes and met the client’s spatial requirements. This case study underscores the importance of thorough stress analysis in the design and implementation of metering skids in flow stations.