Introduction

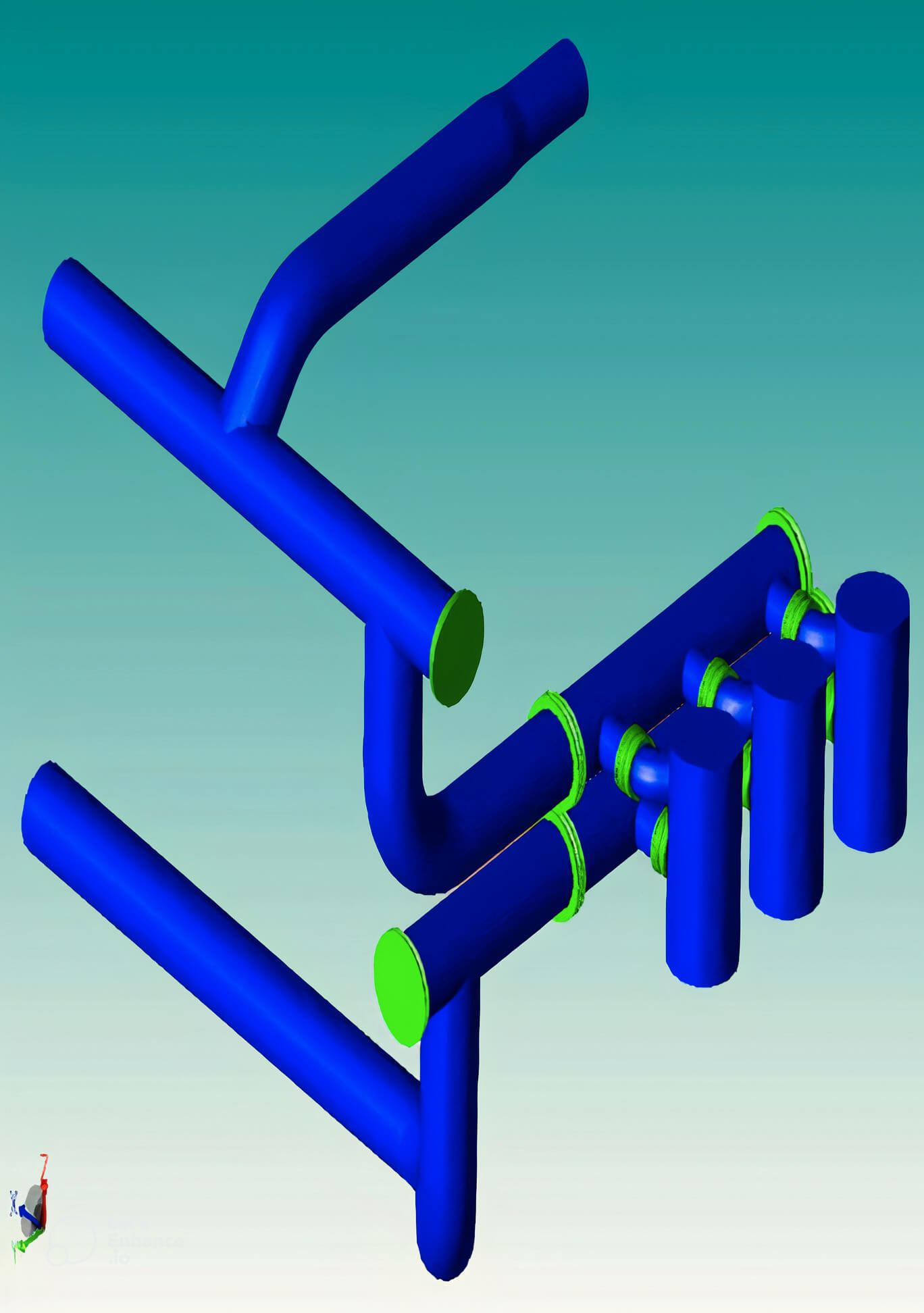

In the current project, a static stress analysis was conducted to assess the performance of GRE headers connected to filter vessels. The purpose was to ensure structural integrity and operational safety. The steel vessels were incorporated into the analysis model to accurately depict the system’s configuration, including overlaps. These vessels were supported and anchored to a steel framework. Additionally, a portion of the associated piping was included in the model.

The client provided crucial data regarding the geometrical specifications, supporting mechanisms, and material properties of the connected FRP headers. This information was pivotal for the analysis process.

Analysis

To carry out the analysis, the CAESAR II pipe stress analysis program was employed. This software enabled the modeling and examination of the entire system. The output yielded valuable insights into pipe stresses, support/nozzle loads, and displacements at various restraint locations. Notably, the highest stresses were evaluated against the standards outlined in ISO 14692. Data necessary for constructing the allowable stress envelope were sourced from the pipe vendor.

Efforts were made to extend the model to encompass realistic boundary conditions pertinent to the scope of the project. However, it was observed that as the model expanded towards its boundaries, the accuracy of the analysis results diminished. Consequently, the results could not be reliably used for assessing the stress levels in the connected piping. It’s worth mentioning that the design standards for the connected pipe adhered to UKOOA guidelines rather than ISO 14692.

Results

Regarding the results, the wall thicknesses of the spool were determined based on the internal pressure design, in accordance with client-specified safety factors. Across all load cases, encompassing both normal operating conditions and design scenarios, the system stresses remained within acceptable limits, aligning with ISO 14692 standards. Although moment loads at the GRP flange connection towards the filter vessel were notable, they resulted from a combined pressure loading of 32 barg, which remained below the qualified pressure threshold for the relevant flanges.