Screw compressors generate pulsations similar to other displacement machines such as reciprocating pumps and compressors. The pulsation suppression devices for screw compressors are also called silencers and are specifically designed to dampen the pulsations generated by screw compressors while also being capable of accommodating the dynamic mechanical loading exerted on the internal area of the silencers.

The silencers of screw compressors typically are different in design mainly because the excitation frequencies are often higher than for reciprocating compressors. This results in differently sized chamber and additional focus vessel wall vibrations.

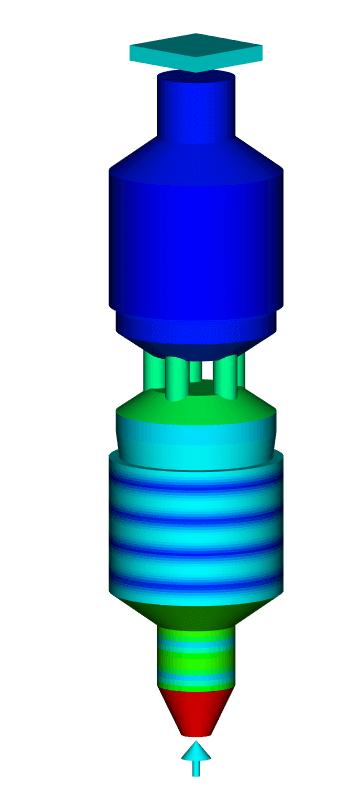

Dynaflow conducted a pulsation analysis using BOSpulse in order to predict the performance of the silencers to reduce the screw compressor excitation. For this purpose, the screw compressor and silencer were modelled using the pulsation analysis software BOSpulse v4.1. No influence of the connecting system was considered for the analysis and the connection to the remaining system was modelled using an anechoic boundary condition. The analysis therefore focused on the performance of the silencers to dampen the pressure fluctuations generated by the screw compressor. The transient (time-dependent) solver of BOSpulse was used for the calculations.

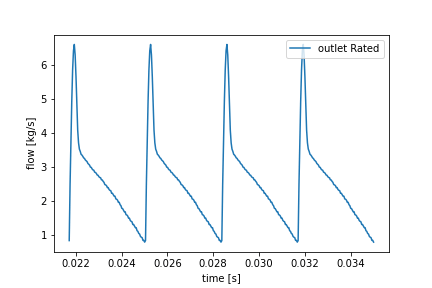

An additional proprietary in-house program was used to calculate the screw compressor flow versus time for both the inlet and outlet at the different process conditions.

The outcome of the study showed performance of the silencers at the different operating conditions in terms of:

- Pulsations transmitted in the connection piping.

- Operating frequency/condition at which silencer performance is optimal.

- Operating frequency/condition at which silencer performance is worst.

- Possibility for improvement in the silencer design including changes lengths of the components and the effect of using Multi-Bore Restricting Orifices.

- Quantifying effects of operations in under and over compression of the screw compressor.

Please see www.bospulse.com and our pulsations and vibrations page for more information.