Introduction

In this case study, the focus was on conducting a stress analysis of the GRE piping system utilized to link the pumps to the tanks at the drilling rig.

Analysis

The analysis operated under the assumption that the 6” and 12” pipes were fitted with rigid tensile-resistant joints. Additionally, it was presumed that the deck and bulkhead penetrations were executed as anchors, involving the welding of steel spool flanges on both sides of each penetration.

To address this, the flexibility of several bulkhead connections was incorporated into the analysis. These flexibilities were integrated into the beam models, which were developed based on the provided isometric drawings. The stress analysis was conducted using CAESAR II, and the resulting stress values were compared against the relevant stress limits outlined in the ISO 14692 code for GRP piping.

To ensure the adequacy of the steel flange, a detailed flange calculation was performed utilizing the AD-Merkblatter methodology.

“Several supports were introduced to reduce loads and stresses in the system.”

Results

From the stress analysis, several key findings could be concluded:

- The introduction of additional supports effectively mitigated loads and stresses within the system.

- Upon reevaluation of the piping layout, it was determined that all pipe stresses remained mild and compliant with the established code limits.

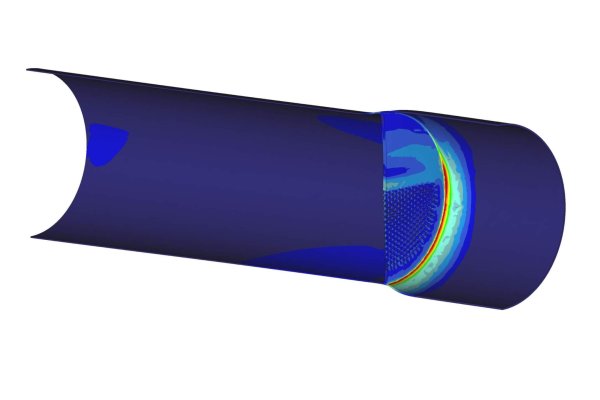

- Excessive flange loads were identified at various points, primarily due to the initial assumption of rigid bulkhead pipe connections. To rectify this, the flexibilities of these connections were assessed using finite element analysis. The revised configuration demonstrated that all stresses and loads fell within acceptable limits.