Challenge of Variable Speed Reciprocating Compressor

The pulsation challenge of a variable speed reciprocating compressorA pulsation analysis according to the API 618 is a good method of preventing excessive vibrations in

Accumulators are used to reduce pressure pulsations from reciprocating pumps by adding volume to the piping. In the preliminary design stage the size and position of the accumulator needs to be determined before the piping design is completed. The performance of the system including the pump and connected piping is a complex interaction between pump excitation frequency and piping/accumulator response. The study to correctly size the accumulator strongly affects noise production, pump valve lifetime and shaking forces. Wrong accumulator sizing can result in system damage at start-up and significant after-installation redesign.

The typical sizing rule used by Original Equipment Manufacturers, shown below, is based on combining the estimated fluctuating fluid volume generated by a pump with the ideal gas law equation. The goal of the analytical sizing method is to determine the minimum gas volume required to reduce the maximum pulsation level to a prescribed percentage of the mean line pressure.

In contrast to this simple approach the outflow of a positive displacement pump has a large frequency component as shown in Figure 1.

Figure 1: Flow rate profile for quintuplex pump, single cylinder (left), combined profile five cylinders (right).

The pulsation levels can be quickly assessed by a computational acoustical simulation (for example in the commercially available software BOSpulse from DRG) using a simple model of a pump, accumulator and simplified connecting piping shown in Figure 2.

Figure 2: Overview of initial quintuplex model used for the computational design method using BOSpulse.

The analytical method has no frequency dependence as shown in Figure 3. The computational acoustical method shows however a large difference in the expected pulsation levels based on the harmonic of the pump rpm.

Figure 3: Initial peak-to-peak pressure pulsation frequency spectrum (no dampener). Triplex (left), quintuplex (right).

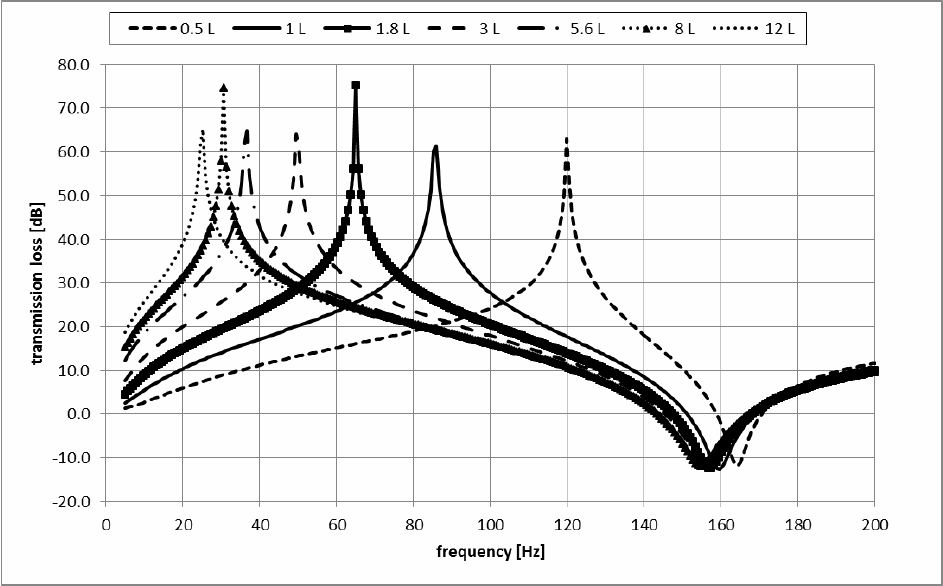

Not only the pump discharge but also the damper has a strong frequency dependence. Using a computational model provides the opportunity to tune the damper to the pulsation frequencies that do not pass the API 674 allowable. The computation acoustic method makes use of the frequency dependence of the accumulator as shown in the transmission loss or damping diagram for various accumulator volumes in Figure 4.

Figure 4: Transmission loss for branch type accumulator with different gas volumes.

The level of safety of the pressure at a certain frequencies with respect to the API 674 allowable maximum pressure is significantly increased by selecting the right accumulator volume (see Figure 5). The estimated pulsation levels based on the analytical method would result in the selection of a 7 liter volume with marginal safety levels. The peak-to-peak pulsation level diagram as function of accumulator volume shows that the parametric (computational) method results in a 3 liter accumulator volume with a high level of safety.

Figure 5: Comparison predicted initial peak-to-peak pulsations analytical method and computational method with API limits, Triplex pump (left), quintuplex pump (right).

The cost of choosing the wrong pulsation damper is many times the cost of a computational acoustical study, and so it makes sense to consider the frequency dependence of the pump and dampener by using a computational model. It is worth emphasising here that the benefits can be gained without modelling the entire piping network.

For more information please check the full paper:

Curious or need more information:

Pulsation analysis done by DRG (including API618/API674)

About DRG as engineering consultant

BOSpulse, pulsation software analysis package

The pulsation challenge of a variable speed reciprocating compressorA pulsation analysis according to the API 618 is a good method of preventing excessive vibrations in

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV