Fiberglass Replacement Pipe: Surge Analysis Case Study

Introduction In a large industrial plant located in the southern Netherlands, a complex pipeline network traverses multiple sections separated by two major highways. This network,

Introduction In a large industrial plant located in the southern Netherlands, a complex pipeline network traverses multiple sections separated by two major highways. This network,

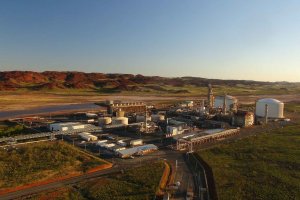

A new off-loading system is under consideration for an ammonia storage plant, designed to transfer ammonia (NH3) from a jetty to three storage tanks. This

The exploration of various methods to enhance the Finite Element Analysis (FEA) of a 6-bed polybed vessel focuses on addressing potential fatigue issues. A Finite

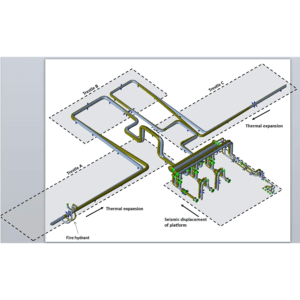

During the design phase of a sea jetty for an oil terminal, Dynaflow Research Group (DRG) conducted a comprehensive stress analysis for the glass reinforced

A comprehensive vibration analysis was conducted on a water feed line operating in a slug flow regime. Slug flow, characterized by large intermittent fluid slugs

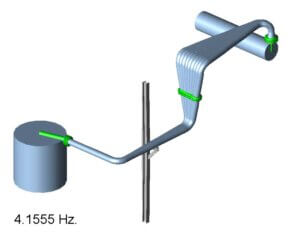

This case study focuses on the vibration assessment of a pentane line, specifically evaluating vibration stresses and the risk of fatigue issues at the nozzle/shell

A fatigue analysis has been done for a reactor feed pressurization drum. The vessel operates under cyclic pressure ranging from 25 psig to 200 psig

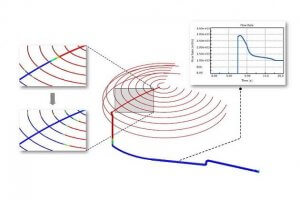

Pressure surges ocurr in piping systems whenever there are sudden changes in flow resistance from steady operation. Surges can cause significant damage, also at locations

Hydrogen generation equipment has an inherent risk for internal explosions, posing an issue to safety. The hydrogen piping and equipment are required to withstand internal

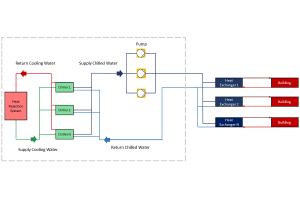

A District Cooling System (DCS) fits the sustainability challenges that our society is challenged with. It provides cooling capacity from a central facility; chilled water

Shell is building a biofuels facility at the Shell Energy and Chemicals Park Rotterdam, the Netherlands (Pernis Refinery) that will have an annual production capacity

Why Pay Attention to a Line Filling Process? During a start-up/line filling process a wave front of fluid progresses it’s way through the empty* parts

DYNAFLOW RESEARCH GROUP (“DRG”) Enters into Reseller Agreement with Quality Professional Software (“QPS”) RIJSWIJK, The Netherlands – January 24, 2024 (Dynaflow Research Group BV) –

Dynaflow Research Group and Seawind Ocean Technology announce collaboration focusing on technical readiness of floating offshore wind applications in the Mediterranean Sea. This landmark partnership

Phone: +31 (0)85 058 0046

E-mail: infoaanvraag@dynaflow.com

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV