Stress Analysis of LNG Bunkering Line: Dynamic and Static Evaluations

At a Liquefied Natural Gas (LNG) plant, a new LNG bunkering line is being constructed to supply ships with liquid LNG. This project involves the

At a Liquefied Natural Gas (LNG) plant, a new LNG bunkering line is being constructed to supply ships with liquid LNG. This project involves the

Since the early 1980s, cracks have been observed in the off-gas cleaning section of the ethylbenzene hydroperoxide (EBHP) reaction unit. To address environmental concerns, EBHP

Finite Element Analysis (FEA) is conducted on the skirt-to-head weld of an Acetylene Converter to evaluate the impact of a hot-box installation. Positioned on the

This case study examines a stress analysis conducted in accordance with ASME VIII Division 1 Boiler and Pressure Vessel Code for a main burner system.

This case study explores the findings from a detailed flow analysis conducted on three different wastewater treatment reactors. In these reactors, component ‘A’ is intended

This case study examines the findings from a comprehensive flow analysis conducted on two identical suction lines connected to VIS Breaker Bottom Pumps. The existing

Flow-induced vibrations in piping systems are a critical aspect of mechanical engineering, impacting the reliability and integrity of various industrial setups. The Japan Society of

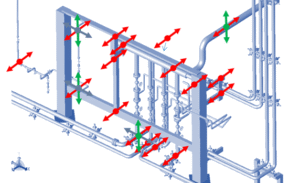

Introduction In the field of engineering design, the precision of pipe flexibility analysis models is critically important for accurately assessing nozzle loads in steel piping

In 2013, a major incident occurred in a Louisiana chemical plant. In a nonroutine operation, plant operators attempted to start a heat exchanger which had

To understand pressure surges in large piping systems, a good place to start is at home. When you finish washing your hands, turning off the

Brief introduction to piping vibrations Vibrations are an oscillatory motion about an equilibrium. The oscillatory movement causes alternating stresses in the system, which, if excessive

The pulsation challenge of a variable speed reciprocating compressorA pulsation analysis according to the API 618 is a good method of preventing excessive vibrations in

On-Demand Webinar Acoustic Induced Vibrations (AIV) and Flow-Induced Vibrations (FIV) are critical phenomena that can lead to significant operational challenges and even catastrophic failures in

On-Demand Webinar Slug flow is a phenomenon that can occur in piping systems, and it’s crucial to evaluate its impact on the system’s integrity. This

On-Demand Webinar In this webinar, we will cover the capabilities of BOSfluids to import PCF files. These files can be generated by different piping design

On-Demand Webinar In this webinar, Frank Bos, partner at Dynaflow Research Group, provides a comprehensive overview of flow-induced vibrations caused by two-phase flow, its mechanism,

On-Demand Webinar A well-designed cooling water system design takes into account the possibility of upset scenarios such as pump failure and water hammer events. For

on-demand webinar En este webinar aprenderas cómo agregar rápida y fácilmente análisis de dinámica de fluidos a su trabajo de análisis y modelado de presión

Excessive vibrations were detected in the discharge piping of compressor C801 at BP Rotterdam. The observed vibration frequencies corresponded to the compressor’s running speed and

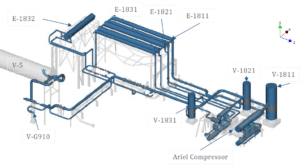

The API 618 DA3 study at the Q8 Terminal, commissioned by Wintershall Noordzee and executed by Dynaflow Research Group, was initiated to ensure the mechanical

Building directly on the preceding site verification and model augmentation phase, the objective of the stress assessment was to ensure the mechanical integrity and regulatory

Following the initial review of the pulsation and vibration analysis for the Q8 Terminal compressor station, a detailed site visit was conducted to resolve ambiguities

This case study presents a critical review of the pulsation and vibration analysis carried out by a third-party supplier, focusing on the Q8 Terminal compressor

The Ærfugl MEG (Monoethylene Glycol) injection skid, engineered by Hitec Products AS for deployment on the Skarv FPSO, is a critical system designed to inject

DYNAFLOW RESEARCH GROUP (“DRG”) Enters into Reseller Agreement with Quality Professional Software (“QPS”) RIJSWIJK, The Netherlands – January 24, 2024 (Dynaflow Research Group BV) –

Dynaflow Research Group and Seawind Ocean Technology announce collaboration focusing on technical readiness of floating offshore wind applications in the Mediterranean Sea. This landmark partnership