Main Burner Stress Analysis Case Study

This case study examines a stress analysis conducted in accordance with ASME VIII Division 1 Boiler and Pressure Vessel Code for a main burner system.

This case study examines a stress analysis conducted in accordance with ASME VIII Division 1 Boiler and Pressure Vessel Code for a main burner system.

This case study explores the findings from a detailed flow analysis conducted on three different wastewater treatment reactors. In these reactors, component ‘A’ is intended

This case study examines the findings from a comprehensive flow analysis conducted on two identical suction lines connected to VIS Breaker Bottom Pumps. The existing

A comprehensive stress analysis was conducted on an assembly comprising two burners and two interconnected chambers. Each burner generates a substantial flame, which combusts waste

The combustion air system of an incinerator is a crucial component for its operation, consisting of a fan, two skids, interconnecting piping, and the incinerator

The installation of a new Glass Reinforced Epoxy (GRE) saltwater system at a chemical processing site required comprehensive support layout planning and stress assessment. This

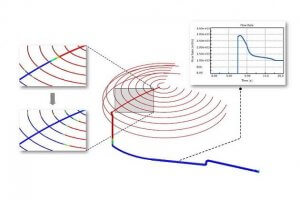

The pulsation challenge of a variable speed reciprocating compressorA pulsation analysis according to the API 618 is a good method of preventing excessive vibrations in

Benefit of computational simulation of a pulsation dampener compared to an analytical method Accumulators are used to reduce pressure pulsations from reciprocating pumps by adding

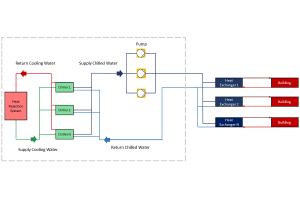

A District Cooling System (DCS) fits the sustainability challenges that our society is challenged with. It provides cooling capacity from a central facility; chilled water

Shell is building a biofuels facility at the Shell Energy and Chemicals Park Rotterdam, the Netherlands (Pernis Refinery) that will have an annual production capacity

Why Pay Attention to a Line Filling Process? During a start-up/line filling process a wave front of fluid progresses it’s way through the empty* parts

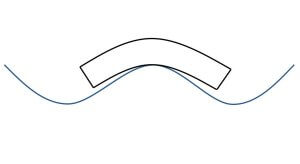

What is Hogging and Sagging and what are the effects on piping? When waves pass over the length of a ship, the ships profile rises

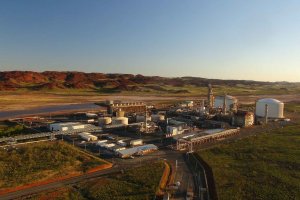

For an ammonia plant in Western Australia, cooling water is supplied by a Sea Cooling water (SCW) as well as a Fresh Cooling Water (FCW)

Dynaflow Research Group has performed a root-cause analysis for a cooling water system that had 3 recent leakages. The failures were in 10” pipe and

DYNAFLOW RESEARCH GROUP (“DRG”) Enters into Reseller Agreement with Quality Professional Software (“QPS”) RIJSWIJK, The Netherlands – January 24, 2024 (Dynaflow Research Group BV) –

Dynaflow Research Group and Seawind Ocean Technology announce collaboration focusing on technical readiness of floating offshore wind applications in the Mediterranean Sea. This landmark partnership

Phone: +31 (0)85 058 0046

E-mail: infoaanvraag@dynaflow.com

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV