Verification of a Continuous Steam Generation System (SGS): Static Stress Assessment

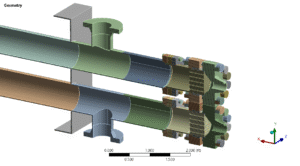

This case study explores the static stress assessment of a continuous steam generation system (SGS) using finite element method analysis. The focus is on a

This case study explores the static stress assessment of a continuous steam generation system (SGS) using finite element method analysis. The focus is on a

This case study presents a comprehensive review of gasholder sizing within a cokes gas network. The primary objective is to evaluate the impact of adjusting

DRG was engaged to conduct a stress analysis for two sulphur recovery burners, adhering to ASME VIII Division 1 Boiler and Pressure Vessel Code. This

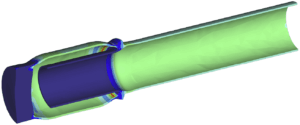

This case study focuses on the finite element analysis (FEA) conducted for a filament wound coupler designed for 42-inch centrifugal cast fiberglass pipes. The objective

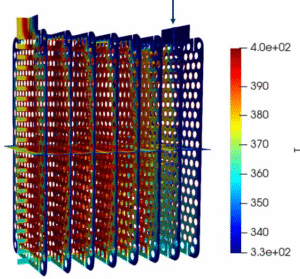

A comprehensive finite element method (FEM) analysis was conducted on a molten salt/oil heat exchanger used in a solar plant facility. This heat exchanger is

In maintenance operations involving a vacuum tower approximately 50 meters in height, additional scaffolding is necessary. This scaffolding introduces increased wind loads, which, in turn,

Introduction Pressure vessels are critical components in a wide range of industries, including power generation, petrochemical processing, and industrial manufacturing. These vessels are designed to

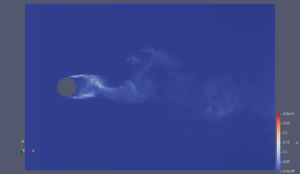

When Theodor von Kármán first discovered vortex shedding in 1911, he likely had no idea how pivotal his work would become for modern engineering, particularly

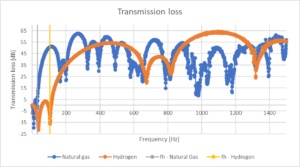

In a previous article, we introduced the risks and design considerations of repurposing an existing natural gas compressor system for hydrogen. That discussion focused on

Hydrogen is considered to be a key element in the energy transition. This molecule is the most notable option for the decarbonisation of hard-to-abate sectors

As part of our responsibilities at DRG, we conduct both standard pressure drop calculations and surge/slug analyses for firewater systems. Our involvement spans various stages,

Geothermal energy is a promising renewable energy source, but it comes with its own set of challenges. Two significant issues in geothermal well operations are

On-Demand Webinar Webinar Overview The webinar on water hammer and fluid transients highlights the significant risks these issues pose to the reliability and integrity of

On-Demand Webinar In this session, we dive into the fundamentals of thermal bowing, exploring its origins in cross-sectional temperature gradients and the potential consequences for

On-Demand Webinar Multiphase flows present significant design challenges across industrial processes. This webinar demonstrates how Computational Fluid Dynamics (CFD) delivers actionable insights for process engineers

DRG CONFERENCE – 35TH ANNIVERSARY The “Innovations that Change the Engineering Industry” conference recently brought together visionaries, professionals, and enthusiasts for an inspiring conference discussing the latest

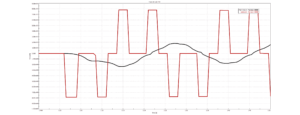

On-Demand Webinar Cyclic loading of both pressures and temperatures can lead to significant structural issues, particularly at welded locations. Fatigue is often the primary cause

On-Demand Webinar During this webinar, Project Engineer, Edwin Schimmel dives into the intricacies of fiberglass pipe stress analysis. This comprehensive webinar will guide you through

This case study presents a technical assessment of the Glass Reinforced Plastic (GRP) piping system installation at a power plant, based on a visit conducted

The client experienced multiple unexpected failures in the underground firewater (FW) network at one of their facilities. The network utilizes fiberglass-reinforced plastic (FRP) piping. To

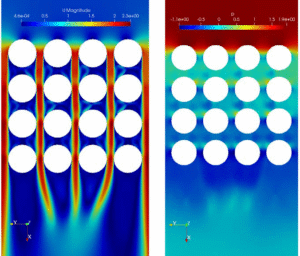

A heat exchanger was found to have fluid leakage from the tube side into the shell side after approximately 3 years of operation. Initial inspections

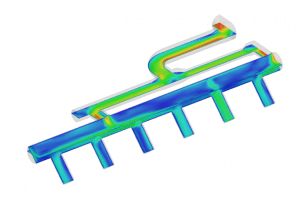

This project presents a detailed technical assessment of two vertical tube cooker (shell-and-tube heat exchanger) designs using Computational Fluid Dynamics (CFD). The analysis was conducted

Dynaflow Research Group was asked to conduct a comprehensive finite element (FE) analysis on a custom hairpin heat exchanger. The primary objective was to assess

Effective mixing in bioreactors is essential for maximizing mass transfer, homogenizing chemical species, and ensuring uniform biological activity. The client undertook a computational fluid dynamics

DYNAFLOW RESEARCH GROUP (“DRG”) Enters into Reseller Agreement with Quality Professional Software (“QPS”) RIJSWIJK, The Netherlands – January 24, 2024 (Dynaflow Research Group BV) –

Dynaflow Research Group and Seawind Ocean Technology announce collaboration focusing on technical readiness of floating offshore wind applications in the Mediterranean Sea. This landmark partnership