Infield inspections Oman – enhancing processes & performance

July 2016

The link between assessment and performance

As engineers, we are happiest when we are out in the field making our customers’ projects run more smoothly. DRG’s niche is the link between assessment and performance, and two projects in Oman recently gave us a chance to combine both worlds for the customer’s benefit.

Enhancing a turnaround project

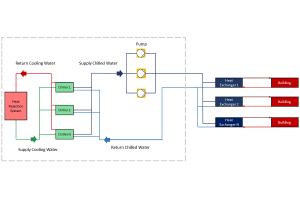

The Refinery Turnaround project for a large Oil & Gas customer took place between February and April. The company was conducting a three-month turnaround project for their refinery, and asked DRG to help investigate and supervise their seawater cooling system. “The system had experienced some ruptures and leaks,” explains Mick Bouman. “As a result, the plant shut down. Starting in 2014, we began to investigate these failures – why they happened, what parts of the system were affected, what were the properties of the materials involved and so on. Then we made our recommendations based on our expertise in stress assessments and surge analysis.”

From documentation to ad hoc engineering

As the team was producing their recommendations, the company selected a contractor, chose their materials and prepared to apply the changes during the turnaround period. They asked DRG to perform two main activities. “First, we reviewed contractor documentation during the months leading up to the turnaround,” explains Bouman. “Then, we used our expertise in GRP piping to provide quality assurance and inspections during the turnaround. We made sure installation was performed correctly and according to good practices by people who were qualified to do the work.” The team also performed ad hoc engineering, providing advice and on-the-spot analysis to assist the contractor on the ground.

Field inspections to optimize performance

A second project helped the Oil & Gas company build a second refinery with increased capacity, incorporating a new seawater cooling system with GRP piping. DRG assisted with the documentation review process, performed field supervision of the EPC contractor, and conducted field inspections to prevent possible long-term stress-related issues.

The customer was pleased with the result: “I would like thank DRG for its support and cooperation during project execution as well as during the existing system inspection. Together, we could identify areas of concern in our existing system and take preventive actions. Similarly for the project work – your support has helped us to quickly find solutions for many problems we faced.” Client Manager Inspection Services.

Both projects were a great way for DRG to do what we do best – help customers enhance their processes and improve the quality of their performance.

For more information, please contact:

Email: Mick Bouman

Project Engineer

+31 85 058 00 46