Introduction

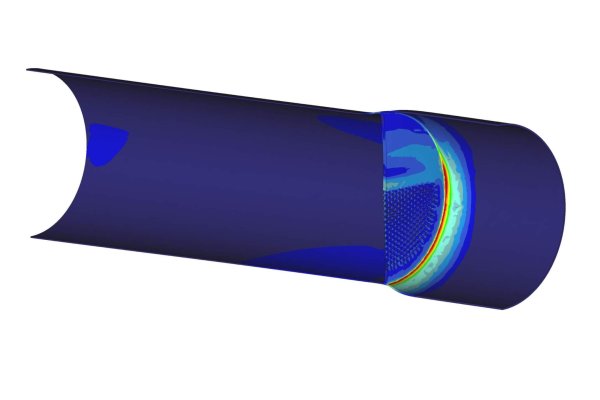

The seawater system was classified as a class A system per the Service Limit State (SLS) standards. Constructed from reinforced fiberglass piping, it comprised a pump manifold housing three pumps, each boasting a rated capacity of 5,500 m3/h. This manifold was connected to two vaporizers via two buried pipes with a diameter of 1200 mm, operating under a design pressure of 8 barg.

Conducting a surge analysis, DRG assessed the system in accordance with the relevant ISO 14692 code governing fiberglass systems. Considering future expansion plans involving a total of five pumps and four vaporizers, the analysis focused on scenarios with two and four pumps in operation, with particular attention to preventing vacuum formation.

Analysis

The analysis performed revealed that the critical scenario involved a pump stop within two seconds, potentially affecting multiple pumps. Ordinarily, the pumps took around 30 seconds to spin down due to their inertia, making a stop within two seconds typically indicative of a mechanical issue, such as a bearing problem. However, the likelihood of more than one pump halting within this short timeframe due to mechanical issues was deemed improbable.

Results

The results indicated that in the event of a pump rundown due to power failure, the predicted spin-down time was sufficiently lengthy to prevent vacuum formation. Similarly, when only one pump was active and stopped within two seconds, the flow rates and velocities remained low, with insufficient inertia in the flowing water to generate significant sub-atmospheric pressures. Even with multiple pumps running and one stopping abruptly, the remaining pumps supplied ample pressure to prevent vacuum formation.

“Installation of vacuum breakers necessary or not?”

Contemplating the necessity of installing vacuum breakers, the analysis of various scenarios led to the conclusion that such installations were unnecessary based on the system’s performance under different operational conditions.