Introduction

In the context of a gas facility, the addition of new units necessitated the enhancement of the existing firewater system. This system was designed to ensure a reliable source of firewater storage, make-up, and distribution capacity to effectively address the plant’s fire safety requirements.

Analysis

The objectives of the surge analyses were as follows:

- Establish maximum and minimum pressures and fire water flow rates under steady-state conditions and various upset scenarios, including:

- Case 1: Pump startup

- Case 2: Hydrant closure

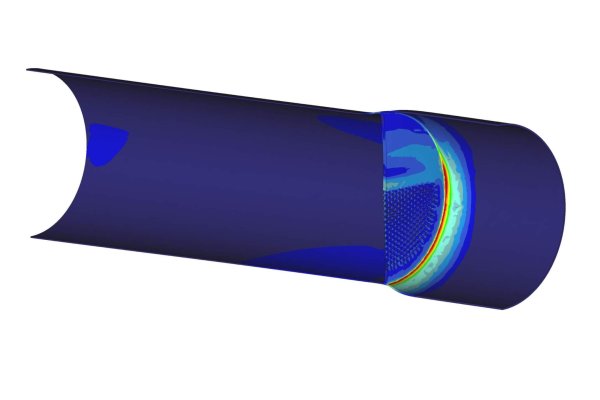

- To protect the firewater network from excessive pressures or vacuums exceeding allowable pipe values measures such as robust tensile-resistant joints (including surge drums, vacuum breakers, and pressure relief devices) were deemed necessary.

- Additionally, it was crucial to determine the rate of pressure change and time histories at specific locations.

Results

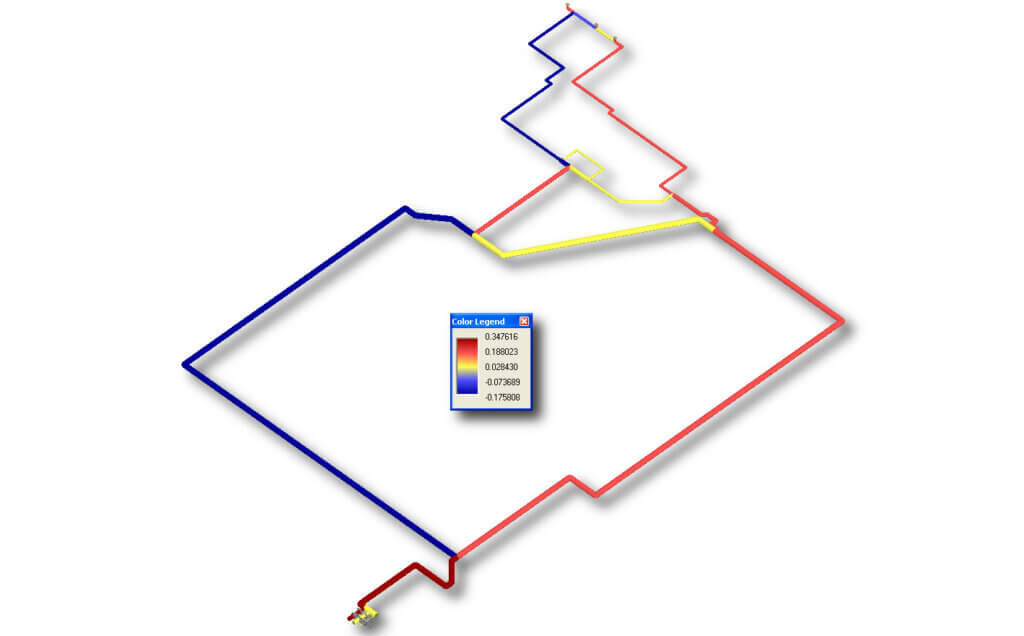

Before the main firewater pump startup and during the opening of hydrants, the pressure in the firewater transfer line dropped to -0.84 barg. Given that the firewater lines were designed to be fully vacuum-resistant under buried conditions, this low-pressure level was deemed acceptable. Furthermore, maximum pressure levels remained within acceptable limits after the main firewater pump was activated.

Of particular significance was the scenario involving hydrant closure. It was identified as a critical case where rapid valve closure could lead to transient pressure peaks surpassing allowable levels.

“One of the most critical cases was the hydrant closure”

To address this, measures were necessary to distribute the closure of open hydrants over a specified time interval and prevent the intermediate time between valve closures from dropping below 0.5 seconds. Alternatively, extending the closure time for each hydrant beyond the 1 second/inch of line size threshold was recommended. By basing closure times on 11/3 seconds/inch of line size, resulting peak pressures could be maintained within allowable limits.