Many industrial processes involve the transport of granular particles in flowing fluids. Simulation of these granular fluid flows is not trivial because of the different time and lengths scales involved, and because of the different nature of the inter-particle and particle-fluid interactions. DRG is trying to overcome these difficulties by developing a coupled CFD-particle solver that is based on OpenFOAM and the in-house particle solver named HADES.

Propagation of polymetallic nodules

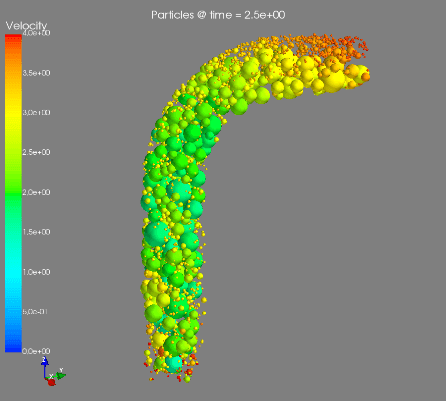

A recent project at DRG involved simulating the propagation of polymetallic nodules through a riser pipe. The aim was to determine the optimal mixture velocity and critical volume concentration for a given riser diameter. A completely resolved interaction between the nodules and the fluid was established, making use of the immersed boundary interface module from the CFDEM®coupling framework.

A vertically oriented straight riser section was modelled, through which nodules of a given size range were propagating upwards. Due to the Buoyant force larger nodules were moving slower than smaller ones, causing various flow patterns to arise. Advanced friction models were applied to both the inter-nodule contact and the nodule-riser contact, allowing the nodules to spin. A bended riser section was modelled to increase chances of nodule blockage while simulating large volume concentrations. The coupled interaction with the fluid was replaced by a special drag force model, taking into account the local flow velocity and mean volume concentration, to allow for sufficient computational performance of these detailed simulations. Time estimates of the effective volume concentration and mean nodule velocity were visualized, to gain valuable insight into the nature of the nodule transport. This would not have been possible with CFD simulations alone; simulation of the particle interactions was essential.

Future Developments

The combination of OpenFOAM and our particle simulator HADES has shown its potential for simulating granular fluid flow. We are currently working on extending HADES and the OpenFOAM interface with better particle-wall contact models and with a more efficient way to handle particles with different shapes and sizes. This will enable us to perform even more complex granular fluid flow simulations in the future.

For more information, please contact:

Harald Ottens

Project Engineer

+31 85 058 00 46