Dynaflow performed an pulsation analysis study for a client where a silencer check was required to dampen the pulsations generated by a rotary lobe blower. A rotary lobe blower is a positive displacement pump which operates by pumping a gas with a pair of lobes. Gas is trapped in pockets surrounding the lobes and carried from the intake side to the discharge side.

The focus of the pulsation analysis was the performance of the silencers to dampen the pressure fluctuations generated by the blower. The transient (time-dependent) solver of BOSpulse was used for the calculations. This type of pulsation analysis considers plane-wave pressure pulsations only.

The shape of the flow pulse coming from the blower needed to be determined. The pulse included both the pulse caused by the gas displacement due to the impeller rotation as well as the backflow pulse into the outlet port due to the higher discharge pressure. The Whispair™ feature was added to the backflow pulse, which consisted of two slots that levels the pressure in the pockets almost to the discharge pressure. A proprietary in-house program was used to calculate the blower flow versus time for outlet at different process conditions.

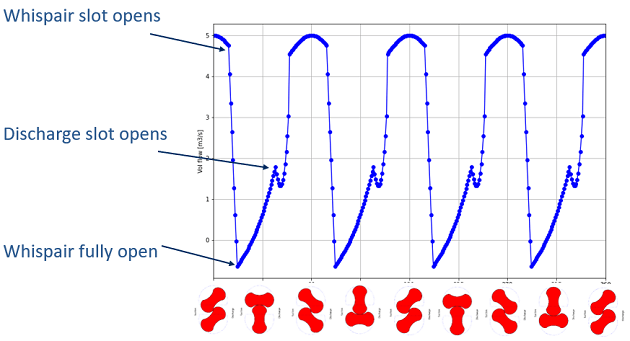

The figure shows the flow pulse shape of the air blower per full revolution. In total four pockets of air are generated per full revolution. When the Whispair™ slot opens, air from the discharge side flows into the pocket due to the higher discharge pressure. This results in a back flow at the discharge side of the blower. The backflow is limited by the size of the Whispair™ slot. When the air pocket reaches the discharge slot, the remaining pressure difference between the pocket and discharge side is equalized. Note that the flow pulse shape depends on the pocket size of the blower, the Whispair™ and discharge slots and the pressure difference over the blower.

Adding the flow pulse of the air blower to BOSpulse demonstrated the flexibility to perform pulsation studies for all types of compressors using BOSpulse.

Please see www.bospulse.com and our pulsations and vibrations page for more information.

Harald Ottens

Project Engineer

+31 85 058 00 46