Introduction

In the analysis conducted for the gas-inlet top box of a heat exchanger, which forms a part of the Torrefaction Tower, emphasis was placed on evaluating its response to static and fatigue loading. Initially, the box was constructed from 253MA material, with a thickness of 5 mm, devoid of any reinforcements. The design aimed for a square geometry, with the top plate directly connecting to the vertical side plates, aligning with production preferences.

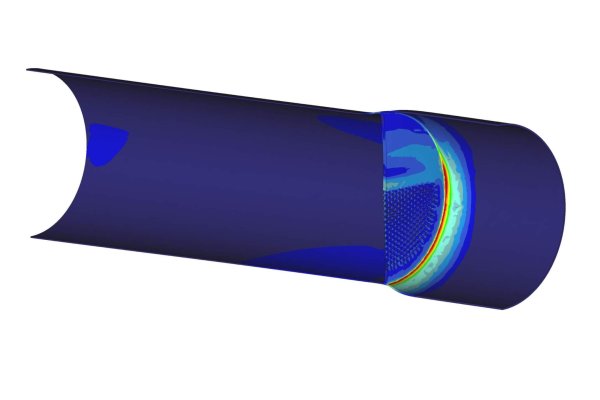

Analysis

Examining the configuration, a 16” inlet box nozzle linked to an 8” stainless steel duct via a flanged reducer was noted. Operating at a temperature of 850°C, the 8” duct necessitated insulation to maintain metal temperatures below 200°C. Additionally, an 1800 mm duct nozzle opposite to the 16” nozzle and an 800 mm diameter manhole for accessibility were observed, with the internal maximum pressure assumed to be 100 mBarg.

Results

The preference for a square geometry, with the top plate directly connecting to the vertical side plates, was reiterated throughout the assessment. Results from the analysis showcased the integrity of the proposed configuration, validating its suitability from both static and dynamic perspectives. Stress evaluations adhered to the rigorous standards outlined in the Pressure Vessel and Boiler Code: ASME VIII Division 2, leveraging sophisticated FE analysis rules tailored for assessing pertinent geometries.