Using CFD for optimizing multiphase process engineering – Q&A Session

What are the key challenges in applying CFD to simulate and optimize multiphase processes in complex industrial systems? The main challenge here is the ability

What are the key challenges in applying CFD to simulate and optimize multiphase processes in complex industrial systems? The main challenge here is the ability

Do CAESAR II formulas for thermal bowing and output results match with FEA? Short Answer: There can be significant differences between the results of CAESAR II and FEA.Explanation:The

A Glass Reinforced Epoxy (GRE) fire water header, installed on a Liquefied Natural Gas (LNG) jetty, comprises DN700 pipes and is subjected to seismic accelerations.

The above-ground seawater supply header is designed to transport seawater from two tie-ins in a discharge manifold of the seawater pumps to AGA. A comprehensive

At an LNG terminal, an unexpected settlement of 12 inches of soil, containing several sections of Vacuum Insulated Piping (VIP), occurred. Because the above-ground pipe

This case study explores the static stress assessment of a continuous steam generation system (SGS) using finite element method analysis. The focus is on a

Table of Contents A Good GRP Code Covers a Large Variety of Products and Loading Conditions A robust Glass Reinforced Plastic (GRP) piping code must

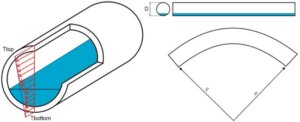

Thermal bowing is a structural phenomenon that arises when a temperature gradient exists across the cross-section of a pipe or vessel. In typical pipe design,

Table of Contents As the demand for flexible, energy-efficient, and reliable compressor operation grows—particularly in hydrogen and process gas applications—our clients increasingly turn to stepless

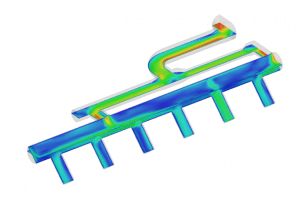

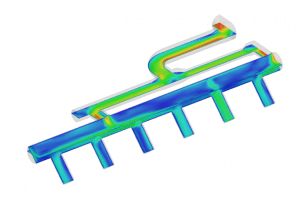

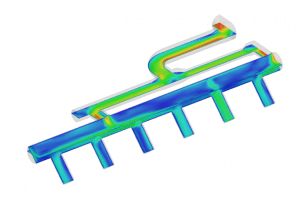

Table of Contents Multiphase flow is a recurring challenge in process engineering, where multiple fluid phases—such as gases, liquids, or solids—interact within the same system.

In the chemical and energy industries, liquid products such as LNG, ammonia, or naphtha are commonly transferred between ships and onshore storage tanks. These transfers

In the engineering domain, accurately simulating transient events in pipeline systems is critical, particularly for essential safety mechanisms such as firewater systems. These systems, typically

On-Demand Webinar Choosing the right GRE piping standard: a comparison of ISO 14692 and ASME NM.2 This webinar offers a detailed technical comparison of ISO

On-Demand Webinar Increasing demand is placed on reciprocating compressors to have more control over the flow rates. Therefore, this session examines how stepless capacity control

On-Demand Webinar Get access to this on-demand webinar that dives into the critical issues of water hammer and fluid transients in pipeline systems. This session

On-Demand Webinar Webinar Overview The webinar on water hammer and fluid transients highlights the significant risks these issues pose to the reliability and integrity of

On-Demand Webinar In this session, we dive into the fundamentals of thermal bowing, exploring its origins in cross-sectional temperature gradients and the potential consequences for

On-Demand Webinar Multiphase flows present significant design challenges across industrial processes. This webinar demonstrates how Computational Fluid Dynamics (CFD) delivers actionable insights for process engineers

Within Europoort Rotterdam, a tankpit of 37m diameter and 21m height was intended to be repurposed for storing a blend of Naphtha and Reformate. Reformate,

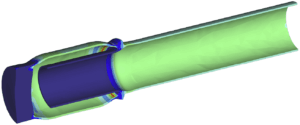

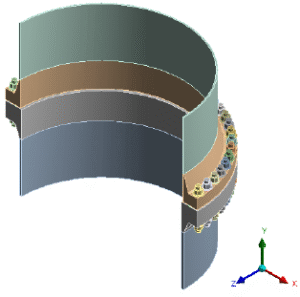

For a coil-wound liquified natural gas (LNG) heat exchanger, an existing 66” and new 72” bolted flange joint have been analysed and reviewed for mechanical

Dynaflow Research Group (DRG) has performed a stress and surge analysis using BOSfluids at Rotterdam Maasvlakte on an extension to their firewater system to accommodate

An existing fiberglass firewater piping system was expanded to enhance its capacity, necessitating validation for the newly added components. The client, engaged in the RDCG

Our client was looking to repurpose a liquid transport and storage system for a different fuel. The new fuel blend has a larger viscosity and

Our client reported multiple cracks at weld locations on a separation tank. These cracks are suspected to be caused by dynamic flow effects from the

DYNAFLOW RESEARCH GROUP (“DRG”) Enters into Reseller Agreement with Quality Professional Software (“QPS”) RIJSWIJK, The Netherlands – January 24, 2024 (Dynaflow Research Group BV) –

Dynaflow Research Group and Seawind Ocean Technology announce collaboration focusing on technical readiness of floating offshore wind applications in the Mediterranean Sea. This landmark partnership