Presentations by keynote speaker Prof. Dr. ir. Ruud Henkes (Shell / TU Delft) and Dr. Andrew Jackson (Engys UK)

The abstracts for the presentations by keynote speaker Prof. Dr. ir. Ruud Henkes (Shell / TU Delft) and Dr. Andrew Jackson (Engys UK) are now available. During the DFC2015 Prof. Dr. ir. Ruud Henkes will present a possible new development concept for Floating LNG while Dr. Andrew Jackson will present a new CFD solver for high accuracy multiphase flow simulations in Oil & Gas.

Splitting of Multiphase Flow from a Single Flowline into a Dual Riser

Dr. ir. Ruud Henkes

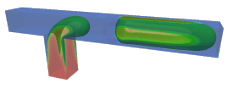

A possible new development concept for Floating LNG may include a single flowline along the sea floor that splits into dual or more flexible risers. Since the gas co-produces condensate and water, design rules are needed for the splitting of the phases at the riser base manifold. Ideally the phase volume ratio of the multiphase flow should be fully equal over the two risers and remain the same as in the flow line. The hypothesis is that maldistribution can occur if the gas flow rate in the risers is so low that it gives churn flow or hydrodynamic slug flow in the risers, whereas an equal split is expected if the gas flow rate is sufficiently high to produce annular flow. To study this we have carried out lab experiments and CFD simulations.

The flow facility at the Shell Technology Centre in Amsterdam transports air and water through a 2”, 100 m long flowline, splitting into dual 15 m high risers, having a diameter of 2” or 1.25”. The pressure is atmospheric at the riser top. For the splitting configuration, we tested both a non-symmetric lay-out (so called Branching Tee) and a symmetric lay-out (so-called Impacting Tee).

A new CFD Solver for High Accuracy Multiphase Flow Simulations in Oil & Gas

Dr. Andrew Jackson

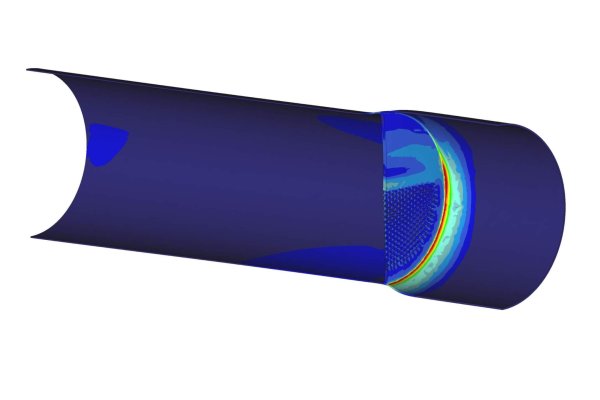

Packed beds and multiphase flows are two common features of industrial processes such as furnaces [1] and reactor vessels [2], and yet the combination of the two is sparsely covered by the literature on numerical modelling. Further applications include wave action on harbour breakwaters [3] and multi-fluid flows in rock beds [4]. In this presentation, we describe our efforts to improve upon the multiphase porous modelling capabilities in the OpenFOAM® toolset.

These developments comprise improvements to the handling of free surfaces on non-orthogonal meshes, as well as a numerical method for handling arbitrary heterogeneous porosity fields, possibly including discontinuities, without introducing instabilities or spurious oscillations. This allows for a general porosity distribution to be specified as just another field. For the two-fluid (free-surface) modelling the volume of fluid (VoF) method is used with the HiRAC [5] interface capturing algorithm. Flow through the porous medium is modelled using the volume averaging scheme of Whittaker [6] and Ergun’s standard model of porous drag [7].

For more information please contact:

Frank Bos

Project Manager

+31 85 058 00 46