DRG’s Richard Fawcett looks at the importance of designing for pressure surges in an LNG bunkering line.

February 2017

In the February issue of LNG Industry Richard Fawcett looks at the importance of designing for pressure surges in an LNG bunkering line.

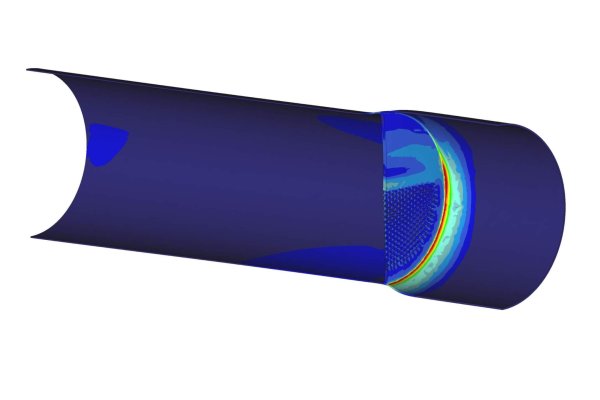

Surge in an LNG bunkering line arises due to rapid upset conditions such as the fast closure of a valve, for instance the ESD valve on the loading arm, or the unexpected tripping of the pump. In the worst case these upset conditions can lead to failure due to excessive pressure or short duration unbalanced forces on the piping.

In this article it is demonstrated how a computation simulation can be used to predict these effects and to show that adequate protection mechanisms are in place. By using this method a robust LNG bunkering line from the perspective of pressure surge can be ensured.

For more information, please contact:

Iris Joele

Marketing & Sales

+31 85 058 00 46

LNG magazine issue February 2017