Floating Head Heat Exchanger Fatigue Analysis

In a new industrial process, an existing floating head heat exchanger is being repurposed. The operational conditions involve cyclic loading, which were not originally considered during its design phase. To evaluate the impact of these cyclic loads on the heat exchanger, Dynaflow Research Group conducted a comprehensive fatigue analysis. Analysis The analysis focused on critical […]

Thermal Analysis of Top Tubesheet Flange Connection in Tail Gas Heater

Introduction Following the replacement of an older tail gas heater, issues with leakage from the top tubesheet flange connection have emerged during production. Despite attempts over two years to mitigate this through different bolt types, materials, and configurations, the problem persists particularly during the heating of the tail gas heater. In response, Dynaflow Research Group […]

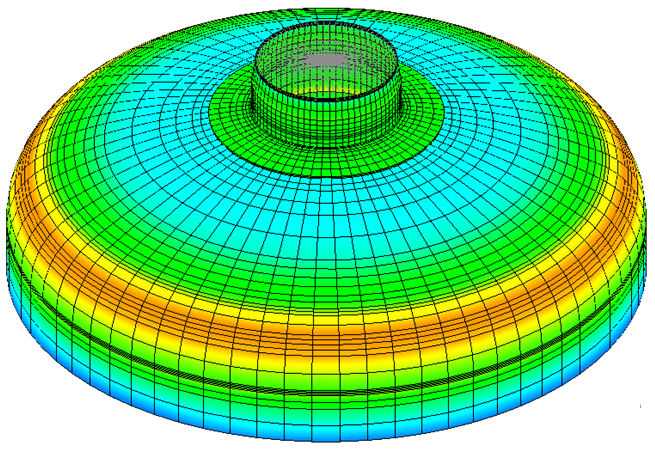

GRP Vessel Sizing: Determination of Wall Thickness According to ASME RTP-1

This case study details the determination of wall thickness for a Glass Reinforced Epoxy (GRE) tank. Analysis The process of defining the wall thickness was conducted in two steps. The initial step involved sizing according to the design rules specified by RTP-1 Subpart 3A “design by rules.” The subsequent step verified deviations from this code […]

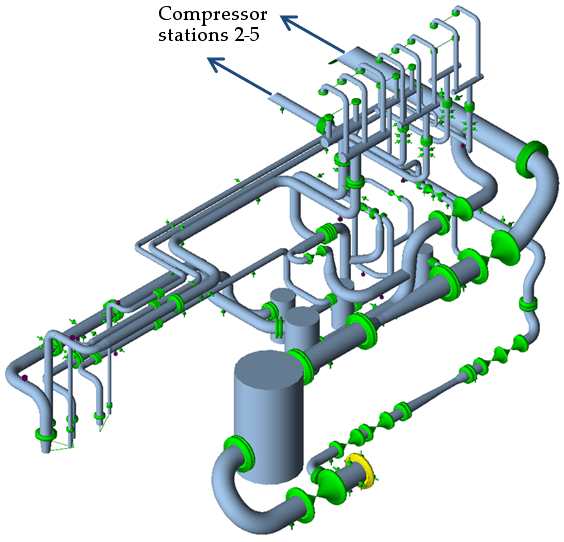

Gas Compressor Station Assessment

A gas compressor station, comprising five similar compressor units connected by an inlet and outlet header, is planned for offshore construction in Mexico. Each unit features three compressor stages that elevate the gas pressure from ambient levels to 95 bar. This substantial pressure increase is accompanied by a significant temperature rise, necessitating the installation of […]

Pipe Stress Analysis for an Oil and Gas Extraction Facility

Dynaflow Research Group (DRG) conducted comprehensive pipe stress analyses for a large oil and gas extraction facility. This facility comprises three onshore flow stations, one offshore flow station, and a gas export compressor station. Crude oil and gas are transported from the wells to the flow stations, where the crude oil and gas are separated. […]

Strength Assessment of a GRE Dump Caisson

A large-diameter seawater dump caisson, constructed from Glass Reinforced Epoxy (GRE), required a comprehensive strength assessment. This caisson featured five nozzles, with one positioned in the blind flange at its top, all subject to external piping loads. The primary objective was to determine the necessary reinforcement for the intersection of the caisson and the nozzles. […]

Static Analysis of a Vessel’s Dividing Wall

Dynaflow Research Group (DRG) conducted a static analysis of a rectifier or afterwash column, which consisted of a carbon steel shell with a 15 mm thick dividing plate welded from wall to wall. The column stood approximately 70 meters tall, with the dividing wall spanning 70% of its height. Both the vessel and the dividing […]

Assessment of a Jetty Pipeline: Combined Pressure Surge and Dynamic Stress Analysis

A steel pipeline was under construction for offloading naphtha from ships arriving at a jetty. A surge analysis was conducted to evaluate the pipeline’s capability under various transient upset scenarios. Following this, a dynamic stress and flexibility study was performed based on the calculated pressure surges. Analysis A transient one-dimensional fluid model of the entire […]

Sulphur Recovery Burners Stress Analysis and Assessment

DRG was engaged to conduct a comprehensive stress analysis for three sulphur recovery burners, in accordance with ASME VIII Division 1 of the Boiler and Pressure Vessel Code. This analysis included both Division 1 calculations and Finite Element Analysis (FEA) to evaluate the impact of loads at the junctions of the nozzles. Each burner assembly […]

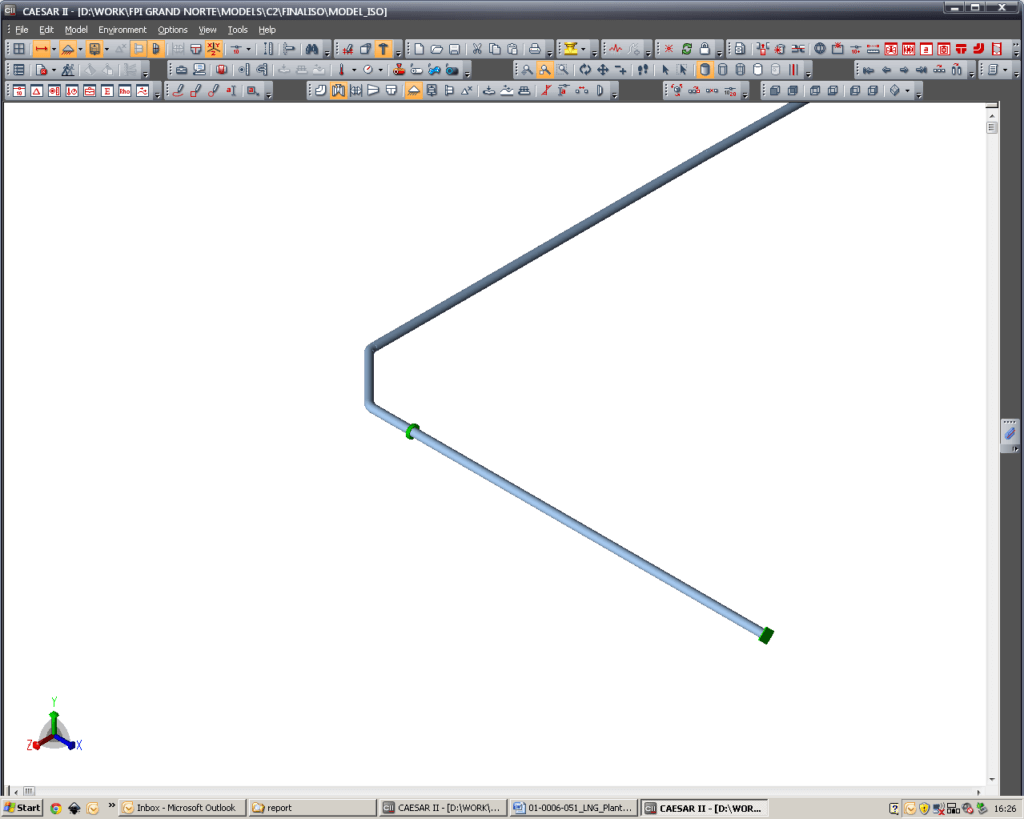

Fire Water System on an LNG Plant: Stress and Surge Analysis

A comprehensive stress and surge analysis was performed for the firewater piping system of an LNG plant located in South America. The system, constructed using Glassfiber Reinforced Epoxy (GRE) pipes, underwent a dynamic response analysis to account for the largest and most critical unbalanced forces. Surge Analysis The existing firewater system comprised two pump connections: […]