Floating Head Heat Exchanger Fatigue Analysis

In a new industrial process, an existing floating head heat exchanger is being repurposed. The operational conditions involve cyclic loading, which were not originally considered

In a new industrial process, an existing floating head heat exchanger is being repurposed. The operational conditions involve cyclic loading, which were not originally considered

Introduction Following the replacement of an older tail gas heater, issues with leakage from the top tubesheet flange connection have emerged during production. Despite attempts

This case study examines the detailed fatigue stress analysis conducted on a heat exchanger used to heat Polyol before it entered a refinery reactor. The

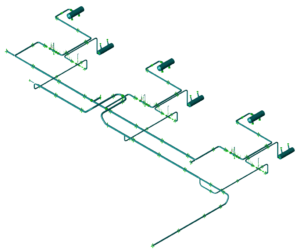

Introduction In the past, visible vibrations were observed in the piping connected to hydrogen compressors. These vibrations were particularly noticeable in the small-bore pipes branching

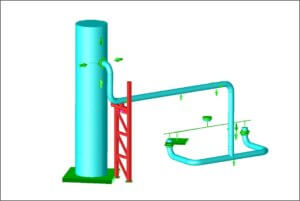

Introduction During the start-up and normal operation phases of a Gasoil Hydrofiner system, significant vibrations were observed in its piping. These vibrations, described as “large

Introduction In this case study, we encountered undesirable vibrations in the downstream line of an angle control valve within a wash oil line. Initially, the

Introduction In this case study, we addressed a notable vibration issue observed in the main 16” line at a chemical plant, which was suspected to

Introduction A serious crack next to a weld in the circulating water flow system was found but it was unclear what had caused this crack.

When do you need to perform a fatigue analyses according ASME BPVC? This webinar explains the screening methods that are provided in ASME-VIII – Div 2.

Piping models that you produce are not 100% accurate. To make sure that uncertainties in design do not immediately result in failures in your piping