GRE Fire Water Header on a Jetty: Static Stress and Seismic Load Analysis

A Glass Reinforced Epoxy (GRE) fire water header, installed on a Liquefied Natural Gas (LNG) jetty, comprises DN700 pipes and is subjected to seismic accelerations.

A Glass Reinforced Epoxy (GRE) fire water header, installed on a Liquefied Natural Gas (LNG) jetty, comprises DN700 pipes and is subjected to seismic accelerations.

The above-ground seawater supply header is designed to transport seawater from two tie-ins in a discharge manifold of the seawater pumps to AGA. A comprehensive

At an LNG terminal, an unexpected settlement of 12 inches of soil, containing several sections of Vacuum Insulated Piping (VIP), occurred. Because the above-ground pipe

The installation of a new Glass Reinforced Epoxy (GRE) saltwater system at a chemical processing site required comprehensive support layout planning and stress assessment. This

Introduction In a large industrial plant located in the southern Netherlands, a complex pipeline network traverses multiple sections separated by two major highways. This network,

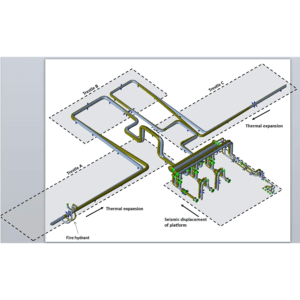

During the design phase of a sea jetty for an oil terminal, Dynaflow Research Group (DRG) conducted a comprehensive stress analysis for the glass reinforced

In the framework of a testing program for glass-reinforced epoxy (GRE) pipes, the long-term material strength properties at a high temperature of 150°C are determined

The client requested a static stress analysis for two cooling water headers, which were to be replaced with headers made from Glass Reinforced Epoxy (GRE).

At an oil refinery plant in Saudi Arabia, a fiberglass-reinforced plastic (FRP) pipe fire water system has been installed, predominantly buried underground. Since its installation,

A 5-inch glass-reinforced epoxy (GRE) transportation line has been installed underground, featuring several above-ground steel pipe connections. Designed to withstand a pressure of 150 bar

Phone: +31 (0)85 058 0046

E-mail: infoaanvraag@dynaflow.com

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV