Actuator Verification and FEM Analysis Conforming to PED Standards

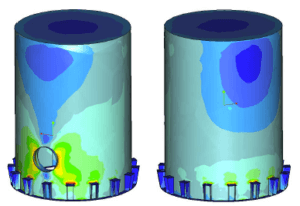

This project presented the assessment results of the analysis of the pressure-containing part of an actuator. The focus was on evaluating the actuator’s integrity through

This project presented the assessment results of the analysis of the pressure-containing part of an actuator. The focus was on evaluating the actuator’s integrity through

In this study, the details and results of the stress analysis performed for the design of two platforms attached to the reinforcement rings of a

This case study detailed the static and dynamic assessment of a Wintrack Tower. Wintrack Towers represented a new geometrical design for suspension towers for high-tension

Dynaflow Research Group conducted a comprehensive stress analysis on three critical components of a high-pressure heat exchanger: the stationary tubesheet, cone-shaped channel, and shell with

This case study examines the thermal stress analysis conducted on three critical components of a high-pressure heat exchanger: Stationary tubesheet Cone-shaped channel Shell including cone

During a certain period, scaffolding was required around three 30m tall depropanizer columns. Since the scaffolding was laterally supported from the columns, all wind loads

Introduction This study presents the findings from a comprehensive stability and stress analysis conducted on a planned high scaffolding construction surrounding a 30-meter-high column. The

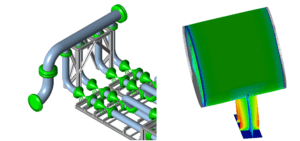

Introduction In this case study, we examine the static stress analysis performed on eight metering skids designed for a flow station. These skids, intended for

This case study discusses the results of a stress analysis conducted on the external section of the pressure equalizing piping at a reactor. The analysis

In this study, the dividing wall of a vessel was subjected to a design pressure differential of 0.03 bar, while the shell had a design

Phone: +31 (0)85 058 0046

E-mail: infoaanvraag@dynaflow.com

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV