Filament Wound Pipe Coupler: Finite Element Analysis

A finite element analysis (FEA) was requested for a fiberglass coupler used in centrifugal cast fiberglass pipes. The aim was to evaluate the structural integrity

A finite element analysis (FEA) was requested for a fiberglass coupler used in centrifugal cast fiberglass pipes. The aim was to evaluate the structural integrity

Two identical spherical tanks, designed and commissioned in the 1960s for the storage of pressurized liquid butane, require re-evaluation for a new purpose. Each tank

A branch connection linking to a high-pressure steam attemperator has experienced a failure, similar to a previous incident. Observations on-site indicate periodic movement of the

This project involves a feasibility study for designing a flue gas duct in a carbon capture and storage plant. The scope includes conceptualizing two large-diameter,

A dryer vessel is designed for the purpose of removing water from ‘wet’ propylene liquid, where ‘wet’ denotes the presence of a small quantity of

A stress analysis was conducted on a tubular heat condenser utilizing finite element analysis (FEA). This condenser configuration includes a rotational asymmetric tube bundle secured

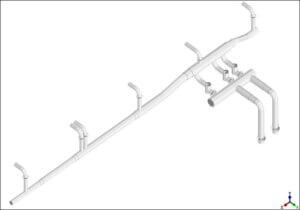

Dynaflow Research Group (DRG) conducted comprehensive pipe stress analyses for a large oil and gas extraction facility. This facility comprises three onshore flow stations, one

Dynaflow Research Group (DRG) conducted a static analysis of a rectifier or afterwash column, which consisted of a carbon steel shell with a 15 mm

DRG was engaged to conduct a comprehensive stress analysis for three sulphur recovery burners, in accordance with ASME VIII Division 1 of the Boiler and

The customer needed to determine the flow split between six cooling towers within a cooling tower arrangement. Analysis The six cooling towers were fed from

Phone: +31 (0)85 058 0046

E-mail: infoaanvraag@dynaflow.com

Laan van Oversteen 20

6th floor

2289 CX Rijswijk

The Netherlands

© Dynaflow Research Group BV