Introduction

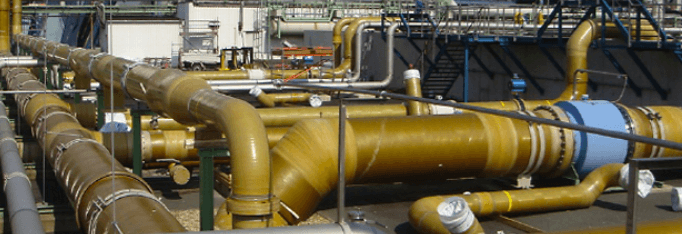

In the context of a greenfield project centered on the construction of a power plant, fiberglass-reinforced plastic (GRP) pipes with diameters of approximately 2.5 meters were selected for the intake and discharge of seawater for cooling purposes. The intake GRP pipes spanned from the pumphouse, which was a component of a concrete structure within a sea dike, extending underground to the condenser of multiple energy generation units. Similarly, GRP pipes extended from the outlet of the condenser, again underground, to the outfall, which was a substantial concrete structure integrated into the sea dike.

To ensure compliance with strength and flexibility requirements, the pipe manufacturer conducted calculations. These calculations were conducted in accordance with the piping code AWWA M45, evaluating circumferential strength and flexibility. However, due to the interaction of the GRP pipes with the sea dikes, Dutch authorities required an additional assessment based on the Dutch codes NEN-3650 and NEN-3651. This assessment, undertaken by DRG, was compared to the AWWA M45 assessment. Nonetheless, NEN-3651 imposed more stringent requirements with higher safety margins, particularly considering the presence of the primary sea wall.

Analysis

The analysis encompassed a comprehensive set of formulas, often referred to as “manual calculations”, addressing various aspects such as ring stiffness, deflection, instability, buoyancy, anchor length, and stress in axial and circumferential directions. These assessments took into consideration numerous factors including overpressure, vacuum conditions, temperature, long-term settlements, installation settlements, soil pressure, traffic loads, and stress concentrations in elbows. Additionally, uncertainties in soil properties were factored in by applying uncertainty factors. In instances where the formulas provided by NEN-3650 and NEN-3651 were inadequate for assessing GRP pipes, calculation methods were devised to facilitate a thorough evaluation. For instance, in the absence of a stress concentration factor for GRP elbows in NEN-3650, principles from the GRP piping code ISO 14692 were utilized.

“The additional assessment proved compliance with Dutch regulations”

Results

The additional assessment demonstrated compliance with Dutch regulations. The calculations incorporated safety factors pertinent to pipes in proximity to sea walls, including a stress safety factor of 0.8 and a pressure increase factor of 1.2. These values were determined based on factors such as population density and the risk of material damage, as prescribed by NEN-3651. The analysis concluded that the installed GRP pipes met the requirements of NEN-3650 and EN-3651, factoring in these safety considerations.