To understand pressure surges in large piping systems, a good place to start is at home. When you finish washing your hands, turning off the tap halts the flow of water. In certain homes and when closing the tap very quickly, you may hear a soft bang as you do so. This is because the water is stopped suddenly which causes a pressure wave to travel through the system: surge.

A pressure surge is an abrupt change of pressure in a piping system, triggered by a transient event such as closing a valve (or the tap). While harmless at home, larger systems can experience excessive surge pressures leading to pipe failure due to the shaking forces caused by these surges. Pressure surge in piping is therefore a phenomenon that needs to be taken into account in the design of a piping system. This includes the structural considerations related to the ability to withstand the shaking forces and operational aspects such as valve opening and closing times and pump start-up scenarios.

What Is Surge?

Surge is a pressure wave that travels through the system. The pressure wave is caused by a change in fluid velocity. The magnitude of the surge depends mainly on the fluid’s velocity change, density, and wave speed. The velocity of the fluid is more important than the operating pressure, surge problems can therefore also occur in low-pressure systems.

Why Is Surge A Problem?

The surge pressure is an addition to the operating pressure and the combination can easily exceed the design pressure in a system. This can lead to permanent deformation and even rupture. In many codes and standards, a higher allowable pressure is specified for surge events as it is a short-term load instead of a sustained load. However, the magnitude of the maximum pressure is not the only problem that a pressure surge can cause.

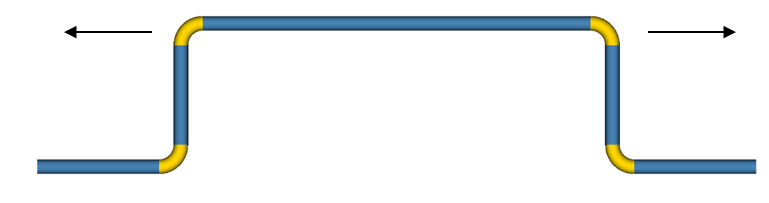

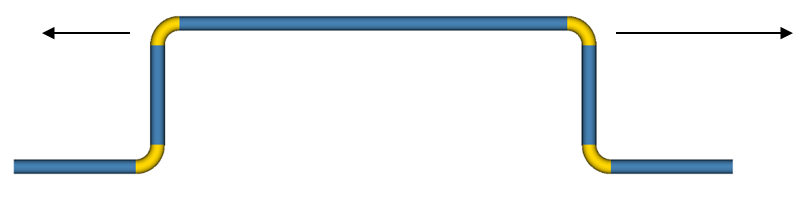

The transient nature of the pressure can also cause problems, as the magnitude of the total pressure can be different in different parts of the system. Normally, the forces due to pressure are balanced, it pushes equally and opposite in a straight section between two bends.

When a pressure wave passes, however, the pressure rises at one bend and not at the other resulting in a net force over that pipe section. This is an unbalanced force.

As the pressure wave travels further into the system, the first bend may be back at its normal pressure while the second has a higher pressure. This causes a net force in the opposite direction.

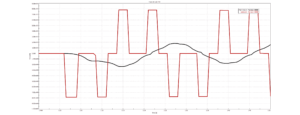

The pressure wave does not just disappear when it reaches the end of the system, instead, it is reflected back and travels back and forth until damped out for example by friction. These unbalanced forces can therefore also go back and forth hence the name shaking forces. This cyclic nature of the forces due to surge means that fatigue could also become an issue.

Piping Issues Due To Surge

Overall, several issues can arise in a piping system due to pressure surges:

- High pressures can cause permanent deformation or rupture of a pipeline.

- Low pressures could cause the total collapse (buckling) of a pipeline or leakage at joints and seals.

- Cavitation and column separation can occur when the pressure drops below the vapor pressure. This in turn can cause high-pressure peaks.

- Reverse flow can be the result of surge pressures and lead to damaging the pump seals and brush gear on motors. This could also lead to the draining of storage tanks and reservoirs.

- Low flow velocity is a realistic problem that occurs in slurry lines, causing settlement of entrained solids and line blockage.

- Large unbalanced loads are the result of traveling surge pressure waves. These loads could cause issues with restraints, flanges, and nozzle connections, i.e. pumps, tanks, and equipment.

- Vibrations and pipeline movement of the mechanical structures can cause high cycle fatigue issues with pipe supports or the pipe itself.

All of this can lead to catastrophic failure of the piping system and equipment or fatigue failure of pipe supporting, instrumentation, and equipment.

Preventing Problems Due To Surge

Predicting and preventing surge is an important step in the design of a piping system. Steady-state and transient calculations must therefore be performed for the most critical scenarios to identify events that can cause pressure surges. The most common transient events that can cause surge are:

- Valve operations (closing or opening control valves)

- Tripping or starting a pump (including the impact of check valves)

- Failure of equipment (heat exchangers)

- The rapid opening of fire hydrants or monitors

With the results of a surge analysis, mitigating measures can be planned to improve the system’s reliability, safety, and performance. Mitigation can include valve operation planning, recirculation lines at pumps, or pressure suppression devices.

For surge analysis, the use of BOSfluids is recommended. This software predicts both steady-state and transient behavior, allowing analysis of maximum surge pressures and dynamic forces. These forces can then be used to perform a structural analysis using the structural interface with a third-party structural stress solver. Mitigation measures can also be tested in BOSfluids, ensuring timely prediction and prevention of surge problems.

With proper planning and design, the effects of pressure surge in a system can be minimized. Whether you prefer a hands-on approach utilizing BOSfluids or seek the expertise of our DRG professionals, we offer comprehensive solutions.

Our expert engineers will conduct a thorough surge analysis for you to identify potential risks for the operation of your system while supporting you in developing measures to mitigate these risks. Mitigation strategies may involve the implementation of surge vessels, vacuum breakers, air valves, changing valve closure or opening times or even re-routing the piping layout. Working hand in hand with your team, our experts will evaluate these measures within the constraints of time and cost, providing tailored solutions for optimal results.

Author: Daniëlle de Jong, Senior Engineer

Resources

Further Reading

Training Available

Learn more about our surge analysis services

Get in touch with one of our team members

Related Articles

Surge Awareness In Firewater Systems

As part of our responsibilities at DRG, we conduct both standard pressure drop calculations and surge/slug analyses for firewater systems. Our involvement spans various stages,

Well Integrity For Fiberglass-Casing Based Well Design

Geothermal energy is a promising renewable energy source, but it comes with its own set of challenges. Two significant issues in geothermal well operations are

Understanding Flow-Induced Vibrations in Piping Systems

Flow-induced vibrations in piping systems are a critical aspect of mechanical engineering, impacting the reliability and integrity of various industrial setups. The Japan Society of