As part of our responsibilities at DRG, we conduct both standard pressure drop calculations and surge/slug analyses for firewater systems. Our involvement spans various stages, from design validation to conducting root cause analyses after system failures. Current codes and guidelines for firewater systems generally require a comprehensive surge analysis only if there is a likelihood of water hammer. This requirement often leaves room for interpretation, typically left to the discretion of the contractor. In this article, we will elaborate on the factors to consider when determining the likelihood of water hammer.

Understanding Water Hammer

Water hammer occurs when the velocity of an incompressible fluid changes rapidly, leading to a proportional change in pressure. The rapidity of this change depends on the system’s response time to the local velocity change. Information travels through piping systems at the speed of sound, which varies from approximately 800 m/s in fiberglass piping to about 1300 m/s in steel piping. Thus, the system’s response time is determined by the total distance the information must travel and the speed of sound in the material.

If the system’s response time exceeds the duration of the velocity change, the pressure change can be described using the Joukowsky equation:

- ∆p is the change in pressure,

- ρ is the fluid density,

- c is the speed of sound,

- ∆c is the change in velocity.

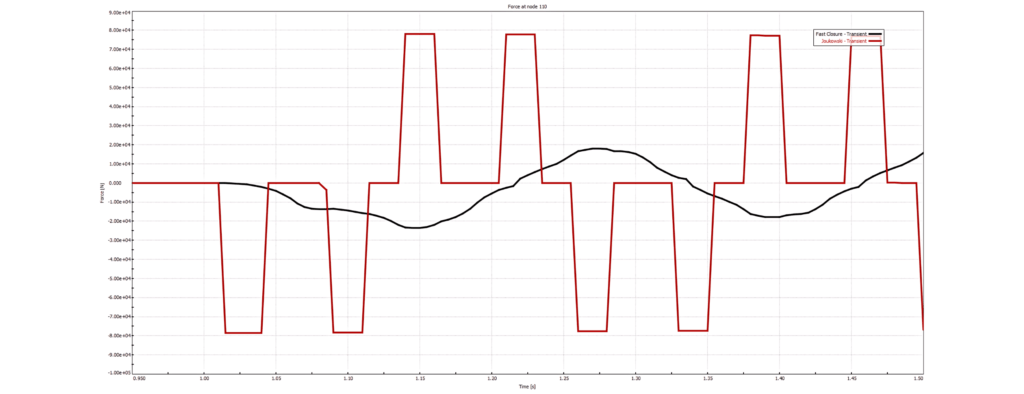

This equation indicates that a velocity change of just 1 m/s can cause a pressure increase of up to 13 barg. However, if the event duration is comparable to or longer than the system’s response time, the pressure peak will be less pronounced. High-pressure surges can lead to system failure due to unbalanced forces and cavitation pockets.

Consider a steel piping system that is 500 meters long, with a pump at the beginning and an open valve at the end, with no other in/out-flows. Under normal operating conditions, the total flow through the system is approximately 6000 L/min, and the flow velocity at the valve is around 6 m/s (6-inch pipe). The system’s response time is calculated as follows:

Therefore, if the valve closes in less than 0.8 seconds, this can result in a pressure increase of 78 barg. If the valve closes more slowly, the pump will have time to react, and the pressure increase will be less significant but still noteworthy.

Causes Of Water Hammer

DRG has encountered many instances of system failures due to water hammer. Some common causes include:

- Slug impact on flow-restricting equipment such as air valves, orifices, partially closed valves, monitors, and sprinklers (e.g., during startup).

- Rapid closing or opening of valves.

- Pump trips.

Most of these failures could have been prevented with a prior surge analysis. To determine whether water hammer could be an issue for your firewater system, consider the following:

- Identify events during system operations that involve changes in velocity (e.g., startup, shutdown).

- Determine the event time for each event (e.g., closure time of a monitor).

- Calculate the system response time for each event.

If the response time of the system is comparable to the event time for any scenario, waterhammer might be a significant concern for your system.

Conclusion

In conclusion, understanding and mitigating the risks associated with water hammer is crucial for the reliability and safety of firewater systems. By conducting thorough surge analyses and understanding the dynamics of fluid velocity changes, system designers and operators can significantly reduce the likelihood of catastrophic failures. It is essential to evaluate potential events that could induce rapid velocity changes and compare these with the system’s response time.

Implementing preventative measures based on these analyses not only ensures compliance with relevant codes and guidelines but also enhances the longevity and operational efficiency of the system. We encourage all stakeholders to prioritize surge analysis in the design and maintenance of firewater systems to prevent avoidable failures and ensure continuous protection against fire hazards.

Related Resources

Further Reading

Training

Share this article

Get in touch with one of our team members