Table of Contents

A Good GRP Code Covers a Large Variety of Products and Loading Conditions

A robust Glass Reinforced Plastic (GRP) piping code must address the full spectrum of products, manufacturing processes, and loading conditions encountered in industrial applications. Unlike steel, GRP cannot yield, so codes must account for unique failure mechanisms such as axial and hoop shear. A good code provides clear guidance on material property limitations—strength, maximum temperature, and long-term behavior—and prescribes how these should be measured.

It also offers recommendations for avoiding failures, such as preventing contact with hard objects, and outlines the analyses required to ensure compliance. Importantly, a comprehensive GRP code encompasses all manufacturing methods (hand lay-up, filament winding, centrifugal casting), resin systems (polyester, vinyl ester, epoxy), and installation scenarios (above ground, buried, pressurized, or ambient duty).

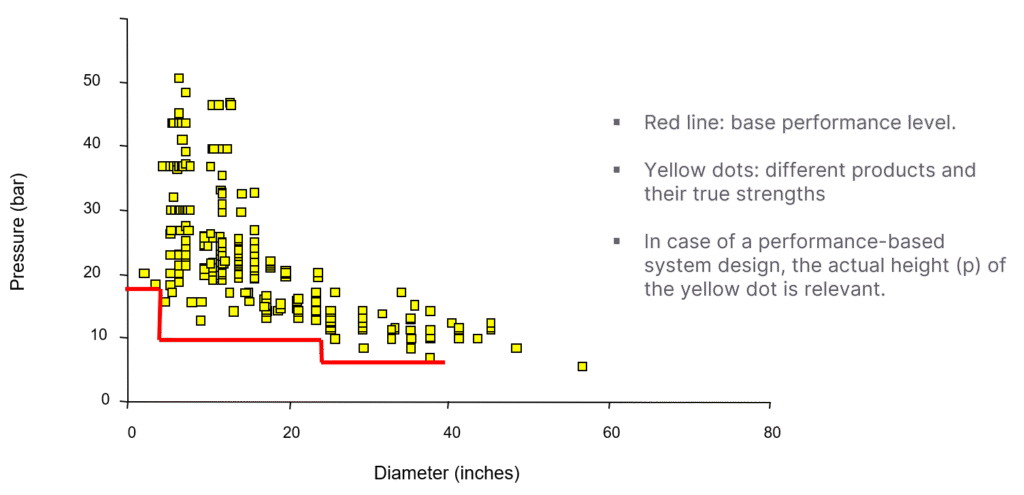

Base Performance Level vs. Performance-Based System Design

GRP standards are built on two fundamentally different design philosophies. The base performance level approach ensures that all products meet a set minimum requirement, regardless of their actual properties. This means that even if a manufacturer produces a superior product, there is no recognition or benefit for exceeding the minimum standard. As a result, manufacturers are incentivized to meet, but not surpass, the baseline at the lowest possible cost.

In contrast, the performance-based system design philosophy tailors the design to the true, tested properties of the GRP components. Here, the actual strength and performance of the product are determined through rigorous testing, allowing for more cost-efficient and innovative designs. Manufacturers are motivated to improve their products, as better performance can directly translate into more competitive system designs.

Example of Both Philosophies

The distinction between these philosophies is evident in the codes themselves. For example, steel piping codes such as ASME B31.3 operate on a base performance level, specifying minimum yield and tensile strengths. Engineers design systems using these minimum values, often unaware of the true properties of the materials used.

Conversely, ISO 14692 for fiberglass piping is performance-based. Here, the actual properties are established through regression and qualification tests, and system calculations are based on these tested strengths. This means that the final design can only be completed once the specific pipe vendor and type are selected, as properties vary between manufacturers.

Choosing the right GRE piping standard: a comparison of ISO 14692 and ASME NM.2

Material Compatibility for Performance-Based System Design

While performance-based design encourages innovation, it introduces challenges regarding material compatibility. Any change in the composition—such as resin, curing agent, or glass type—officially requires a full requalification, including expensive and time-consuming long-term tests. This can severely limit flexibility and slow down innovation.

In practice, some manufacturers may rely on their track record or perform only short-term burst tests to justify material changes, but this does not provide the same assurance as full qualification. The cost and duration of long-term testing remain significant barriers to rapid product development.

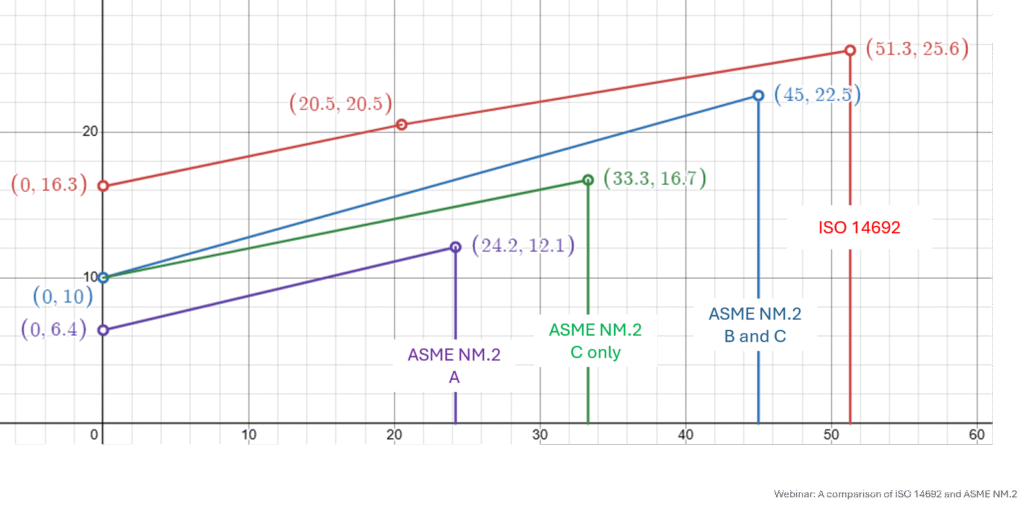

Comparison of ISO 14692 and ASME NM.2

ISO 14692 and ASME NM.2 represent two distinct approaches to GRP piping design and qualification. ISO 14692, first published in 2002, is strictly performance-based and applies to a wide range of applications, including onshore, offshore, and buried piping.

ASME NM.2, introduced in 2018, allows both performance-based and minimum performance system design. However, its scope is limited to piping with internal pressures below 17 bar and a pressure-diameter product below 12.62 bar·m. This means that, for example, a 16 bar pipe must be less than DN750, and a DN1200 pipe must have a design pressure below 10.5 bar.

Overview of Two GRP Codes

ISO 14692 is designed for broad applicability and long-term reliability, requiring extensive testing to establish the true properties of each manufacturer’s product. ASME NM.2, while newer and less widely adopted, offers more flexibility by permitting both performance-based and rules-based design. This flexibility is balanced by higher safety factors when less testing is performed.

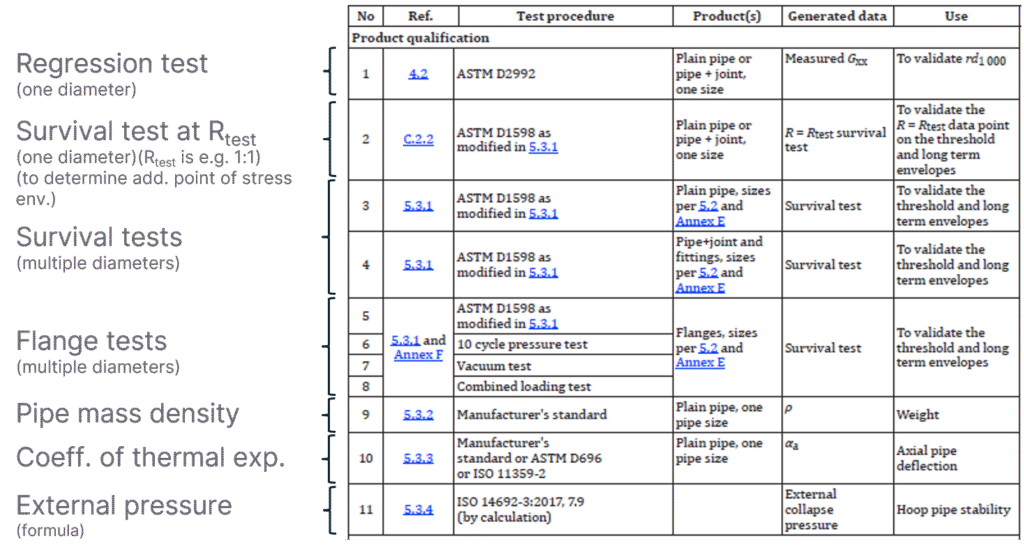

Qualification Requirements in ISO 14692

Qualification under ISO 14692 is rigorous and multi-faceted. It begins with a long-term regression test (ASTM D2992) on a selected diameter of straight pipe, which determines the long-term strength and regression gradient. This test result applies to all diameters and fittings of the same construction.

To verify long-term strength, a 1000-hour survival test is performed for multiple diameters, component types (pipes, fittings, flanges), and joint types (adhesive, laminated, threaded). Additional tests, such as flange tests, coefficient of thermal expansion, pipe mass density, and external pressure resistance, complete the qualification program. Scaling formulas are used to extend results to untested sizes and variants.

Overview of Complete Qualification Program

The ISO 14692 qualification program is structured to ensure that all components meet stringent long-term performance criteria. After the initial regression test, survival tests are conducted at specific biaxial and non-biaxial loading ratios to define the allowable stress envelope. These tests, combined with additional property verifications, provide a comprehensive assessment of the system’s reliability over its intended service life.

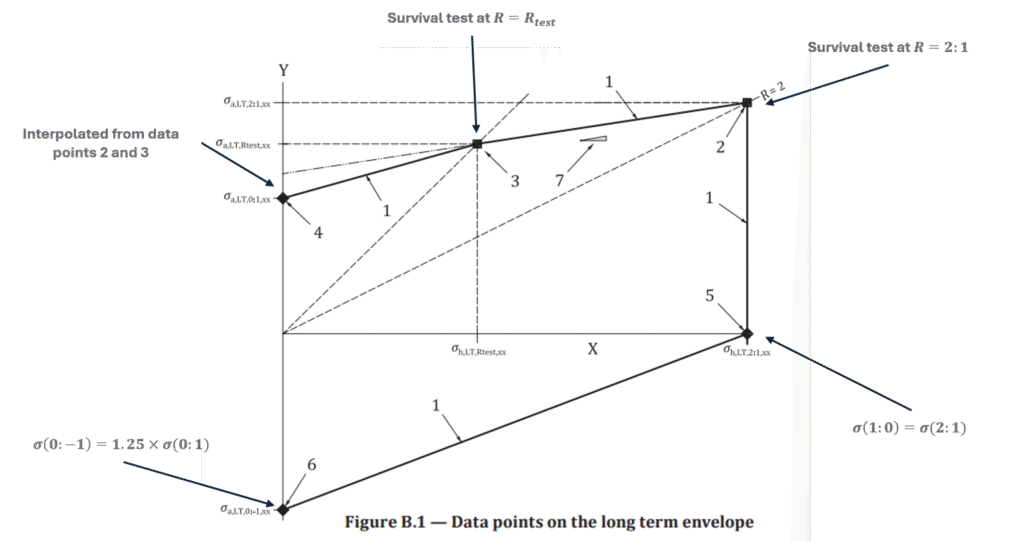

Stress Envelope Obtained from Long-Term Testing

The stress envelope in ISO 14692 is derived from long-term

testing data. Survival tests at different loading ratios—such as 2:1 (pressure

on unrestrained pipe) and 1:1—provide key data points. These are interpolated

to define allowable stresses for axial, hoop, and compressive loads. The

resulting envelope ensures that the design reflects the actual long-term

behavior of the material, rather than relying on conservative estimates or

short-term properties.

Equipment for 𝑹𝒕𝒆𝒔𝒕 Survival Test

To perform the 𝑹𝒕𝒆𝒔𝒕 survival test, specialized equipment is used to create precise biaxial stress conditions. This typically involves two pressure chambers that balance internal and external pressures, allowing for accurate control of the hoop-to-axial stress ratio. The test is conducted over an extended period (e.g., 1000 hours) to capture long-term performance under realistic loading scenarios.

Choosing the right GRE piping standard: a comparison of ISO 14692 and ASME NM.2

Four Design Methods Allowed by ASME NM.2

ASME NM.2 offers four distinct design methods, providing flexibility in how components are qualified:

- Design by Rules (Method A): Uses prescribed allowable stresses based on a fraction (typically 1/8) of the laminate’s short-term strength. No component testing is required, and sizing is done using standard equations.

- Design by Long-Term Testing (Method B): Relies on long-term regression testing to determine hydrostatic design strength, with a total safety factor of at least four from short-term strength.

- Design by Short-Term Testing (Method C): Uses short-term burst and tensile tests, with allowable stresses limited to one-sixth of the short-term strength.

- Design by Stress Analysis (Method D): Employs finite element analysis (FEA) or other stress analysis methods, with allowable stresses based on test-based or default strain limits (factors of six or eight from short-term strength).

Proof-of-Design Testing Requirements in NM.2

When components are not sized using design by rules, ASME NM.2 requires proof-of-design testing. This includes a short-term hydrostatic strength test (one minute at 4.5 times design pressure for a single component, or 3.75 times for three or more components) and a long-term static pressure test (168 hours at 2.5–3 times design pressure).

For filament-wound pipes, a one-hour burst test at four times design pressure is required, though failure is not mandatory. These tests are intended to verify both short-term and long-term reliability, though they do not always capture long-term failure mechanisms as comprehensively as ISO 14692.

Key Differences in Stress Analysis Requirements

Stress analysis requirements differ significantly between the two codes. ISO 14692 provides highly detailed stress intensification factors (SIFs) for various load directions and includes pressure stress multipliers. Load type factors are also more nuanced, with different multipliers for sustained, thermal, occasional, and hydrotest loads. ASME NM.2 simplifies SIFs (using a single value of 1.5) and applies them only to adjacent pipe, not fittings. It also allows for FEA-based qualification, which ISO 14692 does not permit. While FEA offers advantages for unique or complex components, it cannot detect workmanship issues or systematic manufacturing defects, which are better revealed through physical testing.

Hydrotest Requirements

Hydrotest protocols also reflect the differing philosophies. ISO 14692 requires a hydrostatic test at 1.33 times design pressure for 10 minutes, which is far from the failure point and may not reveal weak spots in the system. ASME NM.2 mandates a more robust hydrotest—1.5 times design pressure for up to four hours—bringing the system closer to its long-term allowable stress and increasing the likelihood of detecting poorly designed or manufactured components.

Conclusion

The choice between ISO 14692 and ASME NM.2 depends on the specific needs of the project and the desired balance between flexibility and long-term reliability. ISO 14692 offers a rigorous, performance-based approach that ensures long-term system integrity but requires significant investment in

testing and qualification. ASME NM.2 provides more options for qualification, accommodating a wider range of project requirements and component types, but compensates for reduced testing with higher safety factors. Understanding these differences is essential for engineers and decision-makers seeking to optimize GRP piping system design and ensure compliance with industry best practices.

For more details, check out the fiberglass engineering solutions Dynaflow Research Group offers.