Local wall corrosion of piping and pipe fittings occurs over the system lifetime. The reduced wall thickness of the component can result in the system being deemed unsafe and unfit for service. In these scenarios the corroded component can either be replaced, or an API-579 -part 5 assessment can be performed. If it passes the assesment it confirms the components fitness for service and extending its remaining lifetime.

There are 3 assessment levels to an API-579 part 5 analysis. The level of assessment depends on the type of component and the proximity of the local metal loss to structural discontinuities. Each level increases the complexity of the calculation. Level 3 assesment requires analysis through a finite element analysis package (Note that these assessments are not accepted if the material loss is located on a weld).

Dynaflow Research Group has recently performed several level 1 and 3 assessments resulting in either extended service lifetimes or recommendation of component replacement.

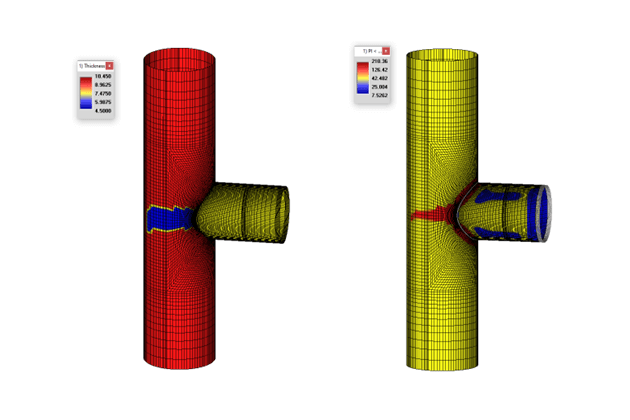

The accompanying image shows one such level 3 assessment, where a 0.037m2 region of local metal loss was found on the run pipe of a tee intersection. Due to the close proximity to the structural discontinuity that is the piping intersection, an API-579-5 level 3 assessment was deemed necessary, with the tee and material loss being modelled explicitly within the FEA package FEPipe. The result of the analysis allowed for an extension of the components serviceable lifetime by 12 years when accounting for predicted corrosion rates.

For more information, please contact:

Harald Ottens

Project Engineer

Phone: +31 85 058 00 46

Visit our Pipe Stress Analysis and Code Compliance page

Visit our Finite Element Analysis page