Introduction

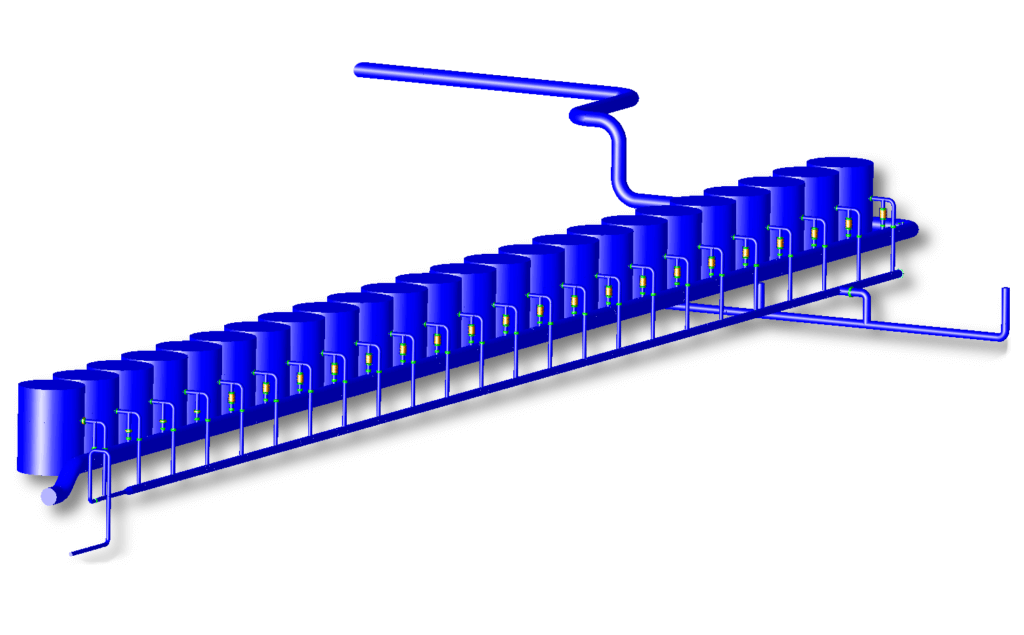

In this case study, we delve into a static stress analysis concerning a distillate water header within a remineralization unit of a desalination plant. This unit comprises two headers, one measuring 1100 mm and the other 600 mm, each featuring 24 tie-in points with branches of 300 mm. Specifically, we examine the necessity of incorporating an additional expansion below to accommodate the thermal expansion of the flushing header.

Analysis

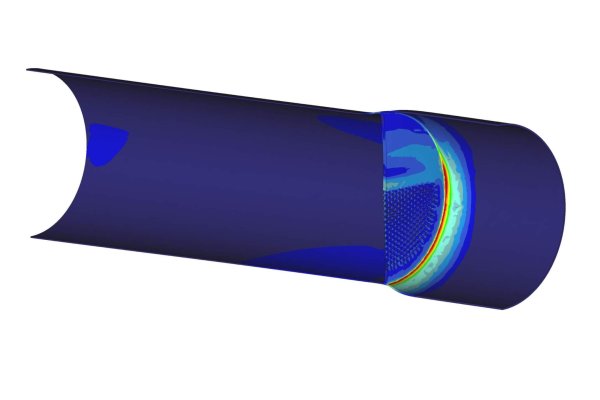

The piping system predominantly consists of above-ground fiber-reinforced plastic (FRP) pipes, while the tanks are constructed of carbon steel with attached nozzles made of stainless steel. To conduct our analysis, we utilized the pipe stress analysis software CAESAR II.

Material properties of the pipes and allowable stresses were derived from data provided by the pipe manufacturer, with stress assessments performed in accordance with ISO 14692 guidelines.

Results

Following our analysis, we arrived at the following design recommendations for a design pressure of 7.0 Barg:

- Installation of an extra expansion bellow on the vertical pipe, to be situated in a pit.

- Application of polystyrene wrapping around the buried pipe section at the junction of the dirty cleaning water header.

- Additional reinforcement of pipes.

Notably, due to the increased displacements of the flushing header pipe, the loadings on the flanges exceed the allowable values for three of the tanks. Hence, we propose the incorporation of heavy-duty flanges at two of these tanks. By utilizing heavy-duty flanges, which possess increased thickness, the tanks can withstand the nominal pressure load.

Upon implementation of the recommended reinforcements, the stresses fall within the allowable stress envelopes for both operating (4.5 Barg) and design (7.0 Barg) conditions.