Introduction

A detailed pulsation analysis was conducted to evaluate the sensitivity of a new Measurement Proving Facility to disturbances. This facility, a piping installation designed to calibrate flow measurement equipment, required an in-depth assessment to understand its response to pressure and flow pulsations. The goal was to ensure accurate and reliable calibration of flow meters by examining the potential impacts of these pulsations.

Analysis

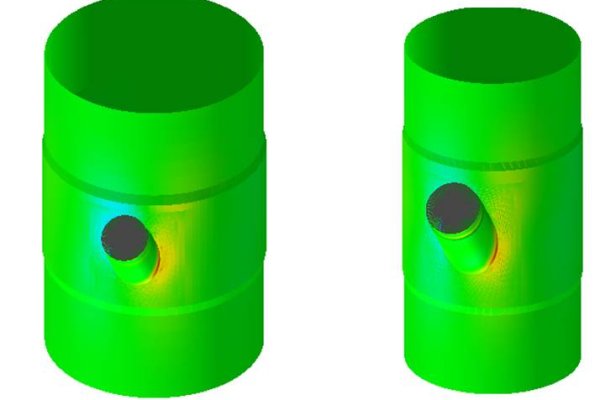

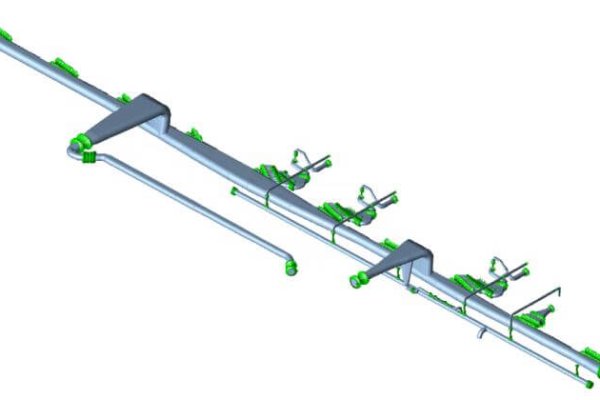

Within the Proving Facility, various flow measurement devices, including turbine and ultrasonic flow meters, were calibrated. The facility was connected to an existing natural gas supply line, which was powered by centrifugal compressors. These compressors introduced flow pulsations that could potentially excite the system’s acoustic and mechanical natural frequencies. Acoustic resonance, which amplifies pressure pulsations, could result in excessive noise, induce structural vibrations in the piping network, and affect the system’s operation.

A sensitivity study was performed to understand how pressure fluctuations from the upstream centrifugal compressors influenced pressure levels at different calibration points. This analysis considered various scenarios with different configurations of operating filters, heat exchangers, and measurement devices. Due to uncertainties in the precise location of the compressors, a harmonically varying input pressure was assumed to represent the compressors. The study varied both the frequency and amplitude of the pressure disturbances to obtain a comprehensive understanding of the system’s sensitivity to these pulsations. The analysis followed guidelines from the VDI and API standards.

Results

By varying the parameters of pressure pulsations, the sensitivity of the Proving Facility was thoroughly explored. This exploration provided valuable insights into how pressure pulsations at the calibration locations related to the induced pulsations from the centrifugal compressors. The results led to recommendations on mitigating the effects of these pulsations to ensure accurate calibration of flow measurement equipment.

Conclusions

The pulsation analysis of the Measurement Proving Facility highlighted the importance of understanding and managing pressure and flow disturbances. By assessing the sensitivity of the calibration system to these pulsations, the study provided crucial advice on how to relate pressure pulsations at calibration points to those induced by centrifugal compressors. This analysis ensures the facility’s ability to perform precise and reliable calibrations, ultimately enhancing the accuracy of flow measurement equipment in practical applications.