Using CFD for optimizing multiphase process engineering – Q&A Session

What are the key challenges in applying CFD to simulate and optimize multiphase processes in complex industrial systems? The main challenge here is the ability

What are the key challenges in applying CFD to simulate and optimize multiphase processes in complex industrial systems? The main challenge here is the ability

Do CAESAR II formulas for thermal bowing and output results match with FEA? Short Answer: There can be significant differences between the results of CAESAR II and FEA.Explanation:The

A Glass Reinforced Epoxy (GRE) fire water header, installed on a Liquefied Natural Gas (LNG) jetty, comprises DN700 pipes and is subjected to seismic accelerations.

The above-ground seawater supply header is designed to transport seawater from two tie-ins in a discharge manifold of the seawater pumps to AGA. A comprehensive

At an LNG terminal, an unexpected settlement of 12 inches of soil, containing several sections of Vacuum Insulated Piping (VIP), occurred. Because the above-ground pipe

This case study explores the static stress assessment of a continuous steam generation system (SGS) using finite element method analysis. The focus is on a

Table of Contents A Good GRP Code Covers a Large Variety of Products and Loading Conditions A robust Glass Reinforced Plastic (GRP) piping code must

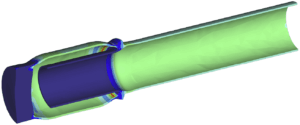

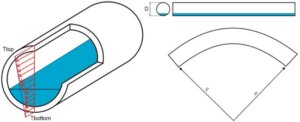

Thermal bowing is a structural phenomenon that arises when a temperature gradient exists across the cross-section of a pipe or vessel. In typical pipe design,

Table of Contents As the demand for flexible, energy-efficient, and reliable compressor operation grows—particularly in hydrogen and process gas applications—our clients increasingly turn to stepless

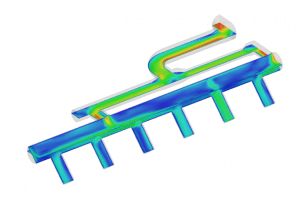

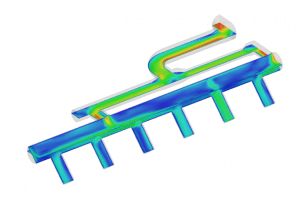

Table of Contents Multiphase flow is a recurring challenge in process engineering, where multiple fluid phases—such as gases, liquids, or solids—interact within a single flow

In the chemical and energy industries, liquid products such as LNG, ammonia, or naphtha are commonly transferred between ships and onshore storage tanks. These transfers

In the engineering domain, accurately simulating transient events in pipeline systems is critical, particularly for essential safety mechanisms such as firewater systems. These systems, typically

On-Demand Webinar In this session, you will be able to learn more about how to quickly and easily add fluid flow analysis to your existing

Excessive vibrations were detected in the discharge piping of compressor C801 at BP Rotterdam. The observed vibration frequencies corresponded to the compressor’s running speed and

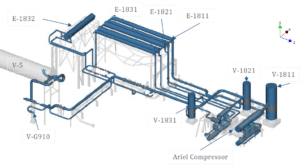

The API 618 DA3 study at the Q8 Terminal, commissioned by Wintershall Noordzee and executed by Dynaflow Research Group, was initiated to ensure the mechanical

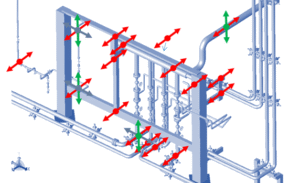

Building directly on the preceding site verification and model augmentation phase, the objective of the stress assessment was to ensure the mechanical integrity and regulatory

Following the initial review of the pulsation and vibration analysis for the Q8 Terminal compressor station, a detailed site visit was conducted to resolve ambiguities

This case study presents a critical review of the pulsation and vibration analysis carried out by a third-party supplier, focusing on the Q8 Terminal compressor

The Ærfugl MEG (Monoethylene Glycol) injection skid, engineered by Hitec Products AS for deployment on the Skarv FPSO, is a critical system designed to inject

DYNAFLOW RESEARCH GROUP (“DRG”) Enters into Reseller Agreement with Quality Professional Software (“QPS”) RIJSWIJK, The Netherlands – January 24, 2024 (Dynaflow Research Group BV) –

Dynaflow Research Group and Seawind Ocean Technology announce collaboration focusing on technical readiness of floating offshore wind applications in the Mediterranean Sea. This landmark partnership