Fluid Flow Analysis & Simulation

Flow issues can critically impact the efficiency, safety, and reliability of your pipeline or installation. Dynaflow Research Group specializes in identifying and resolving these challenges through advanced fluid flow services, including Computational Fluid Dynamics (CFD), surge analysis, and pulsation studies.

Our expertise ensures optimal operation across your system’s entire performance envelope.With years of experience and cutting-edge tools, we provide tailored solutions to analyze and mitigate flow-related problems. Whether it’s enhancing system design, improving performance, or safeguarding profitability, our services are designed to keep your operations running smoothly and efficiently.

Flow Analysis Expertise

Optimize Flow Efficiency with Advanced Fluid Flow Services

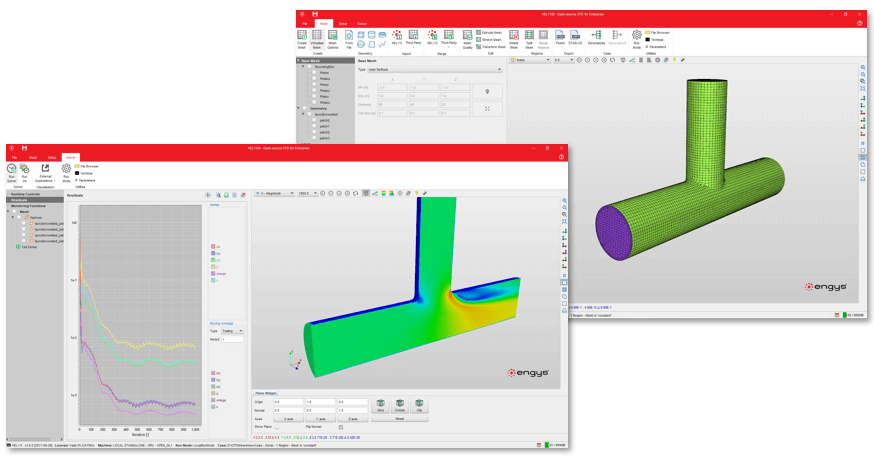

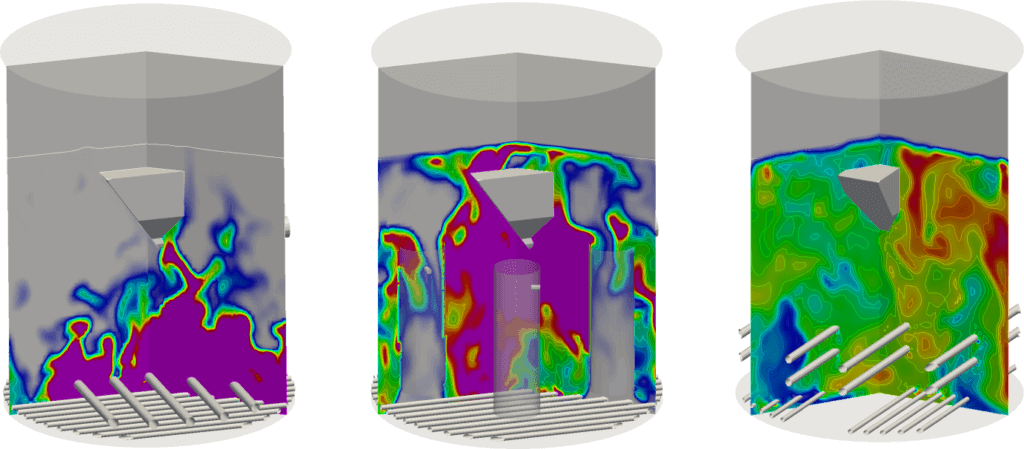

CFD simulations offer a detailed understanding of complex flow patterns within your systems, such as slug catchers, separators, and multi-phase flow lines. By using industry-leading tools, we provide accurate modeling of fluid behavior, ensuring that your system functions efficiently under a variety of operating conditions.

Benefits

- Enhanced flow distribution and performance.

- Reduced risk of slugging, erosion, or other flow disturbances.

- Optimized design for multi-phase flow equipment.

Benefits

- Prevention of damage due to sudden pressure changes.

- Extended lifespan of piping and equipment.

- Improved safety and operational reliability in high-pressure environments.

Pulsations in pipelines, particularly in multi-phase systems, can cause structural vibrations and mechanical failures. Through our pulsation studies, we analyze acoustic and mechanical vibrations to identify pulsation sources and provide mitigation strategies that enhance system safety.

Benefits

- Minimized risk of mechanical failure from pulsations.

- Reduced acoustic resonance and vibration in piping systems.

- Improved reliability and longevity of compressor and pump operations.

APPLICATIONS

Fluid Flow Project Examples

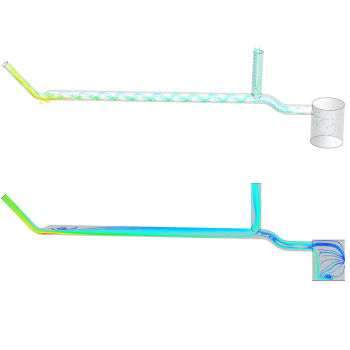

CFD Analysis of the Two-Phase Flow in the Finger of a Slug Catcher

The two-phase flow in a finger-type slug catcher is analyzed using CFD techniques to ensure stratified flow for liquid separation, employing Ansys CFX and OpenFOAM simulation tools.

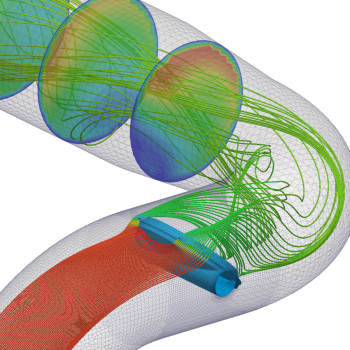

CFD Analysis of the Flow Around a Butterfly Valve

The study analyzed flow around a butterfly valve using OpenFOAM to verify actuator sizing, focusing on torque-valve opening relationships, stationary flow behavior, and minimal piping influence on forces and moments.

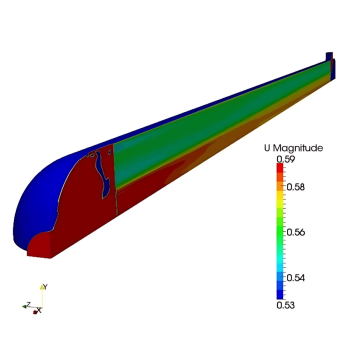

CFD and Thermal Calculations of the Pre-heating of a Heat Exchanger

A CFD study using OpenFOAM predicted hot air velocity distribution in a heat exchanger to analyze thermal gradients between tubes, preventing buckling. Detailed thermal results were obtained via custom FEA software.

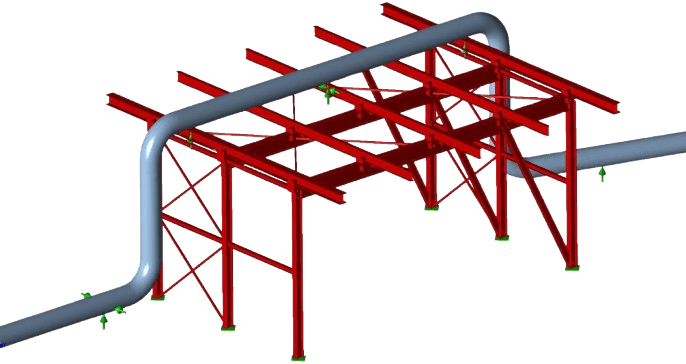

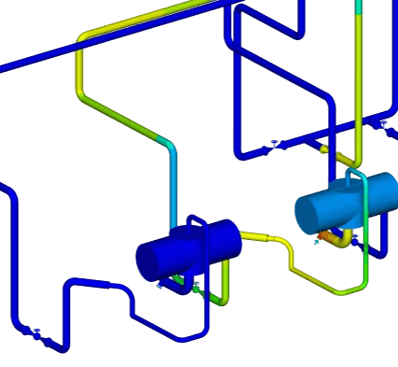

LNG Bunkering System: Surge Analysis

A surge analysis for a 600-meter LNG bunkering line was conducted to ensure safe operations, focusing on worst-case scenarios, surge mitigation strategies, and optimizing emergency valve and pump coordination.

Preventive Analysis Of A Fiberglass Ballast System On A Vessel

A surge and static stress analysis for an FRP ballast water system identified excessive surge pressures from rapid valve closures and layout rigidity causing stress issues. Flexibility improvements were recommended to prevent recurrence.

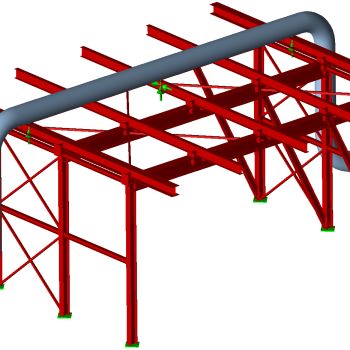

Analysis of a 1.6 km Long Jetty Pipeline

A jetty pipeline’s surge and dynamic stress analyses identified excessive stresses during transient upsets. Valve closure adjustments were proposed to mitigate unbalanced forces, ensuring compliance with design code limits.

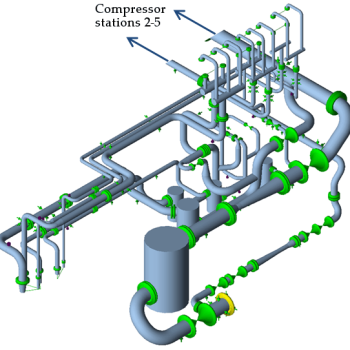

Gas Compressor Station Assessment

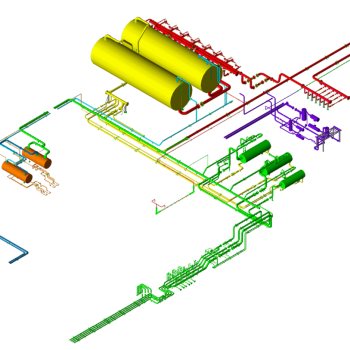

Pipe Stress Analysis for an Oil and Gas Extraction Facility

DRG conducted static and dynamic pipe stress analyses for an oil and gas facility, resolving overstress issues via support modifications, rerouting, and flange upgrades, ensuring structural integrity and operational efficiency.

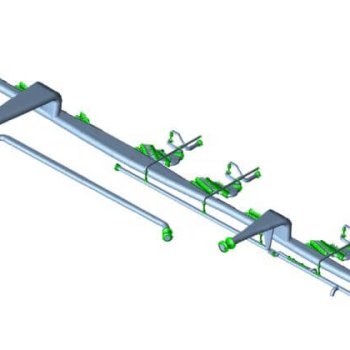

Pulsation Analysis for a Flow Station

DRG resolved vibration issues at a Nigerian Flow Station by conducting pulsation and mechanical response analyses, recommending support modifications to mitigate dynamic stresses, ensuring system reliability, and enhancing performance.