Fiberglass Engineering - Design Support

Optimized design from the start is key to preventing future operational issues. With our design support services, we focus on creating durable and efficient fiberglass piping systems by selecting the right materials, optimizing pipe thickness, and ensuring proper support layouts.

Using tools such as Finite Element Analysis, we ensure your fiberglass components, including vessels and tanks, are built to handle operational demands, reducing time and costs over the project’s life cycle.

FIBERGLASS EXPERTISE

Fiberglass Design and Quality Control Engineering Services

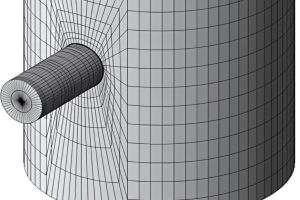

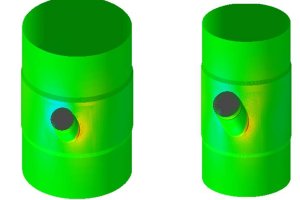

In fiberglass piping, non-standard component geometries can make traditional testing methods costly and impractical. At Dynaflow Research Group, we address this with Finite Element Analysis, offering a solution for challenging geometries.

Why Choose DRG’s FEA for Special Components?

- Accurate Modeling: Our FEA models reflect the unique, non-uniform fiberglass material properties found in real-world production, providing reliable data on stress and strain limits.

- Cost-Effective Optimization: By simulating performance and reducing the need for multiple prototypes, we minimize qualification testing failures and cut qualification costs.

- Versatile Applications: Ideal for large bore pipes, vessels, and tanks where hydrotesting is challenging, our tailored FEA solutions ensure reliable, long-lasting performance.

We specialize in determining and reviewing the optimal wall thickness for Fiberglass Reinforced Plastic piping systems. Our approach is tailored to your specific application needs and integrates vendor-specific design standards to ensure your pipes are built for purpose. By thoroughly analyzing your project’s unique specifications, DRG ensures your FRP piping system remains safe, durable, and fully compliant with industry regulations.

Why Choose DRG for Wall Thickness Design?

- Customized Calculations: We evaluate the exact requirements of your system, ensuring that the selected wall thickness meets both performance and durability expectations, while complying with ISO 14692 standards.

- Material Qualification: Our calculations are aligned with a rigorous material qualification program to ensure long-term operational reliability.

- Analysis for Complex Components: Special fittings and components may require Finite Element Analysis (FEA) to assess additional lamination needs based on stress analysis data and composite properties.

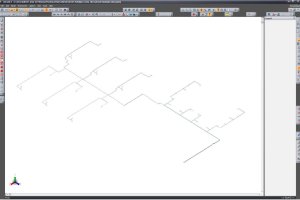

A well-designed pipe support layout is crucial for a reliable, code-compliant piping system. At DRG, we leverage extensive experience across diverse piping systems and operating conditions to design and optimize support arrangements tailored to your project’s requirements and budget.

Why Choose DRG for Pipe Support Design?

- Customized Solutions: We design support systems that align with structural steel locations, ensuring they can handle operating loads in both static and dynamic conditions.

- Specialized Designs: For fiberglass piping, we provide custom-made solutions such as tailored support shoes that account for the unique challenges of FRP compared to steel piping.

- Advanced Mechanical Analysis: When needed, we apply Finite Element Analysis to validate that both the pipe sections and support shoes meet strength and functionality requirements.

Setting up a new fiberglass product line demands rigorous testing and strict quality control to meet industry standards and ensure performance reliability. This is why we provide expert support in designing fiberglass components such as flanges and fittings, while also helping you develop complete Qualification and Inspection Test Plans (ITPs).

Why Choose DRG for Your Fiberglass Testing and Q.C?

- Optimal Material Selection: We guide you in selecting the best raw materials based on your application, ensuring the ideal balance of strength, stiffness, and chemical resistance.

- Performance Verification: With most fiberglass standards being performance-based, we emphasize pressure testing to confirm each component’s strength and ensure the system meets all specifications. These tests generate critical data for stress analyses and system integrity assessments.

- End-to-End Quality Assurance: DRG ensures quality at every stage of production by reviewing and advising on ITPs and attending vendor meetings to ensure robust testing protocols are in place. We also perform factory inspections and audits to verify the entire production process, from adhesive bonding to pipe handling and storage.

Fiberglass composites are widely used in industrial systems for tanks and pressure vessels (PV) due to their exceptional corrosion resistance. However, precise design and evaluation are crucial to ensure these components meet the operational demands of your system. Dynaflow Research Group (DRG) provides the specialized expertise needed for designing high-performance fiberglass equipment.

Why Choose DRG for Fiberglass Equipment Design?

- Expert Engineering: Our engineers understand the unique mechanical behavior of fiberglass composites, using Finite Element Analysis to accurately size and design wall thicknesses for tanks and vessels, ensuring structural integrity under all operating conditions.

- Optimized Design Process: Our advanced approach minimizes the need for costly physical testing by refining designs through FEA, saving time and resources while maximizing reliability.

- End-to-End Support: DRG guides you through the entire process—from initial design through manufacturing and inspection—addressing safety concerns and ensuring compliance with all quality and safety standards.

Fiberglass Engineering Applications

Fiberglass Engineering Project Examples

Stress Analysis of a GRE Firewater Piping System

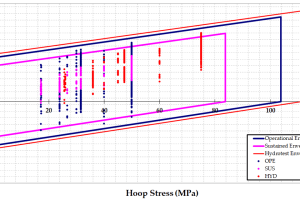

Stress analysis of a GRE firewater piping system identified necessary design modifications to ensure ISO 14692 compliance and system reliability.

Fiberglass Fire Water System: Stress Analysis

Stress analysis of an FRP firewater system identified vulnerabilities, including thrust block settlements and high stresses, with recommendations for reliability improvements.

Static Stress Analysis of GRE Cooling Water Headers

Static stress analysis of GRE cooling water headers identified stress challenges, requiring design modifications, flange assessments, and rerouting for ISO 14692 compliance.

Stress Assessment of GRP Sea Water Dump and Produced Water Caissons

Stress assessment of GRP caissons identified excessive nozzle stresses, requiring increased pipe pressure ratings and laminate thickness for ISO 14692 compliance.

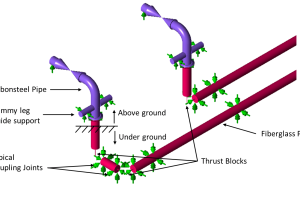

Stress Analysis of Underground Fiberglass Sea Water Network

Stress analysis of an underground fiberglass seawater network identified necessary reinforcements, protective measures, and anchor placements for ISO 14692 compliance.