Fiberglass Engineering - Analysis Support

We offer a range of analysis services focused on fiberglass piping, including stress, surge, and vibration analysis for both new and existing systems. Our experienced team uses advanced techniques to identify potential risks and ensure your systems meet ISO 14692 industry standards.

Our fiberglass experts provide clear insights and practical solutions, including onsite assistance and supervision during installation, maintenance, or root cause analysis after a failure. We are committed to helping you improve the performance and durability of your fiberglass piping infrastructure.

Fiberglass EXPERTISE

Comprehensive Fiberglass Piping Stress and Vibration Analysis

Fiberglass Reinforced Plastic piping is widely used in industrial settings. However, ensuring its safety and performance under various conditions requires stress analysis services. Identifying potential issues early will help you prevent costly failures and ensure long-lasting, reliable operation for your FRP piping systems.

Why Choose Dynaflow for Your FRP Stress Analysis?

- Expert Evaluation: Our engineers analyze pipe stress, flange loads, and nozzle loads to confirm they fall within safe, allowable limits. We focus on system flexibility, ensuring all components meet critical design code requirements.

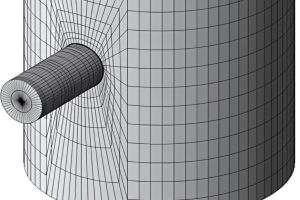

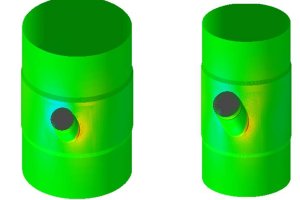

- Advanced Techniques: We employ advanced methods such as Finite Element Analysis (FEA) for more complex systems and in-depth evaluations.

- Up-to-date Standards: We integrate the latest Stress Intensification Factors (SIFs) and flexibility guidelines for tees and bends, ensuring complete static integrity.

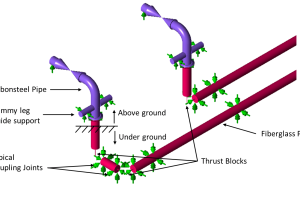

Buried piping introduces unique challenges such as soil settlement, backfill resistance, and road crossing loads, all of which can lead to uneven stress distribution and deformation. We specialize in addressing these complexities, ensuring the structural integrity of buried Fiberglass Reinforced Plastic systems.

Why Choose Dynaflow for Your Buried Piping Stress Analysis?

- Comprehensive Evaluation: We assess critical factors such as ground movement, soil pressure, and expansion restraint to prevent overstress conditions.

- Dynamic Interaction Analysis: Our team evaluates the interaction between the pipe and surrounding soil, identifying stress points at bends and joints to minimize risk.

- Tailored Solutions: We consider key factors like soil type, compaction, and pipe stiffness, offering solutions such as thrust blocks or flexible joints to absorb stresses.

In addition to analytical solutions, DRG provides on-site supervision and expert advice during installation and failure investigations, ensuring proper trench sizing, bedding, and backfill compaction for the long-term reliability of your buried FRP systems.

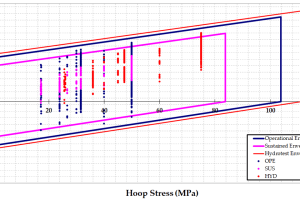

Surge events and water hammer pose significant risks to fluid systems, particularly those made with fiberglass piping, which is more susceptible to high-pressure peaks than steel. Sudden flow changes from valve operations or pump trips can cause excessive surge pressures, leading to an increase in pipe stress, which could cause potential system failure.

Why Choose Dynaflow for Surge Analysis?

- Transient Modeling: We model surge and transient events in detail, identifying their impact on the system’s structural integrity.

- Targeted Risk Mitigation: Based on our analysis, we provide practical solutions to reduce surge pressures, unbalanced loads, and related risks such as cavitation and reverse flow.

- Protection for Fiberglass Systems: Our surge analysis ensures that your FRP systems are safeguarded from pressure peaks and structural damage, keeping your operations safe and efficient.

Whether it is a new or existing system, DRG’s multidisciplinary approach ensures you can take the right mitigation measures to protect your fiberglass piping against the pressure shocks arising from surge events.

Vibrations in piping systems, often caused by interactions between the transported medium and mechanical components, can lead to energy waste, noise, and mechanical failures due to fatigue. Fiberglass piping, with its lower stiffness and susceptibility to resonance, is particularly vulnerable to these vibrations.

Why Choose Dynaflow for Vibration Analysis?

- Root Cause Identification: Using vibration measurements, modal analyses, and mechanical response assessments, we diagnose the underlying causes of harmful vibrations.

- Tailored Solutions: We combine structural and transient flow analyses to address vibrations caused by varying flows, pumps, or process conditions, preventing fatigue and pulsation failures.

- Focused Expertise: Our experience with fiberglass pipelines ensures that we effectively mitigate vibration risks, preserving the integrity of your system.

Fiberglass Engineering Applications

Fiberglass Engineering Project Examples

Stress Analysis of a GRE Firewater Piping System

Stress analysis of a GRE firewater piping system identified necessary design modifications to ensure ISO 14692 compliance and system reliability.

Fiberglass Fire Water System: Stress Analysis

Stress analysis of an FRP firewater system identified vulnerabilities, including thrust block settlements and high stresses, with recommendations for reliability improvements.

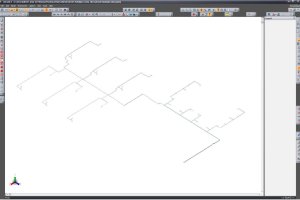

Static Stress Analysis of GRE Cooling Water Headers

Static stress analysis of GRE cooling water headers identified stress challenges, requiring design modifications, flange assessments, and rerouting for ISO 14692 compliance.

Stress Assessment of GRP Sea Water Dump and Produced Water Caissons

Stress assessment of GRP caissons identified excessive nozzle stresses, requiring increased pipe pressure ratings and laminate thickness for ISO 14692 compliance.

Stress Analysis of Underground Fiberglass Sea Water Network

Stress analysis of an underground fiberglass seawater network identified necessary reinforcements, protective measures, and anchor placements for ISO 14692 compliance.